As the manufacturing industry continues to evolve, the role of Connected workers has become increasingly crucial. These workers, empowered by digital tools like FAT FINGER, are the driving force behind flexible manufacturing systems. FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence.

Understanding Flexible Manufacturing Systems

Flexible manufacturing systems (FMS) are designed to adapt quickly to changes in product design and volume. They are characterized by their ability to handle various products simultaneously, reducing production time and costs. The key to their flexibility lies in the integration of advanced technologies and the role of Connected workers.

The Role of Connected Workers

Connected workers are those who utilize digital tools and technologies to enhance their productivity and efficiency. They play a pivotal role in enabling FMS by providing real-time data, facilitating communication, and ensuring seamless operations.

- Real-time Data: Connected workers provide real-time data that is crucial for decision-making processes. For instance, FAT FINGER’s dashboards offer real-time visibility into operations, enabling quick adjustments and improvements.

- Communication: Digital tools like FAT FINGER facilitate seamless communication among workers, ensuring everyone is on the same page and reducing the chances of errors.

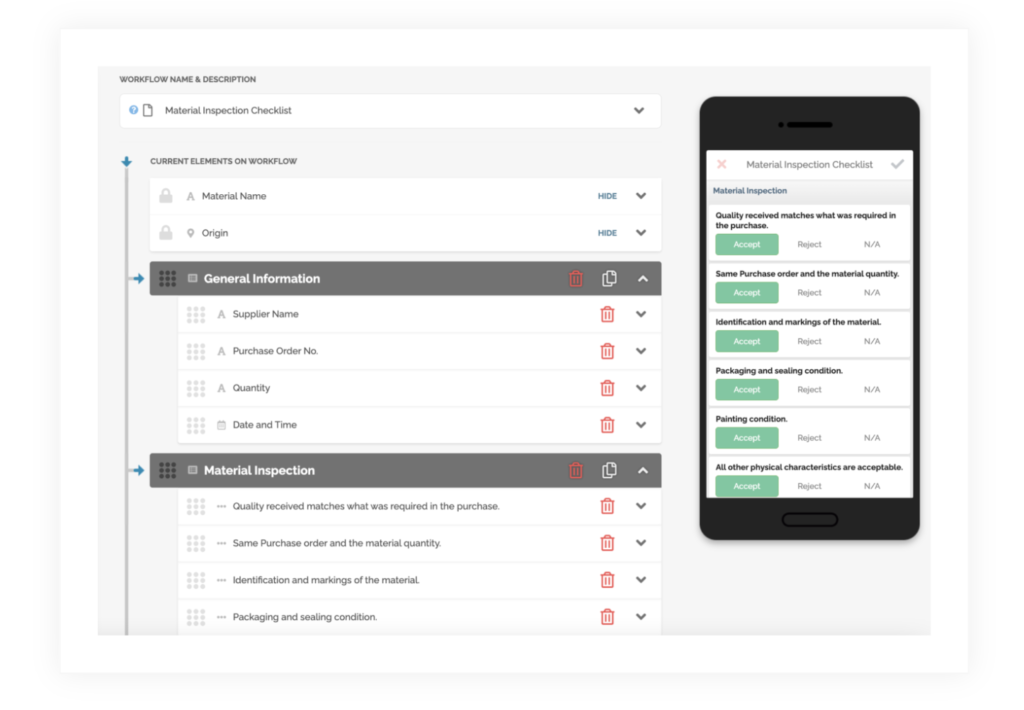

- Seamless Operations: With features like a drag & drop workflow builder, mobile & desktop workflows, and augmented reality, FAT FINGER ensures smooth operations, contributing to the flexibility of manufacturing systems.

Case Study: FAT FINGER in Action

A great example of the role of Connected workers in enabling FMS is seen in the use of FAT FINGER in various safety, maintenance, and operations areas. These include:

- Safety: Take 5 Safety, Near miss reporting, JSA / JHA, Risk Assessment, Incident reporting, Journey report

- Operations: Material Inspection, Quality Control, Shift Handover, Facility inspection / Production rounds, Line Changeover, Field ticket

- Maintenance: Work Order Checklist, Truck inspection checks, Mobile Asset Inspection, Shutdown / Turnaround form, Preventive maintenance inspection, Predictive Maintenance

By using FAT FINGER, companies can ensure that their workers are connected and empowered to perform their tasks efficiently and correctly every time, thereby enabling a more flexible manufacturing system.

The Future of Flexible Manufacturing Systems

As technology continues to advance, the role of Connected workers in enabling FMS will only become more significant. With the integration of IoT devices and artificial intelligence coaching, FAT FINGER is at the forefront of this evolution, providing the tools necessary for workers to stay connected and perform their tasks efficiently.

Conclusion

The role of Connected workers in enabling flexible manufacturing systems is undeniable. By utilizing digital tools like FAT FINGER, these workers can provide real-time data, facilitate communication, and ensure seamless operations, all of which are crucial for the flexibility of manufacturing systems. As technology continues to advance, the role of Connected workers will only become more significant, making tools like FAT FINGER even more essential.

Ready to empower your front-line teams and enable a more flexible manufacturing system? Try FAT FINGER for FREE or request a demo today.