As the oil and gas industry continues to evolve, the role of technology in enhancing Operational Efficiency and safety cannot be overstated. One of the most transformative technologies in this sector is Artificial Intelligence (AI). AI, particularly in Predictive Maintenance for Oil Rigs, is revolutionizing the way the industry operates. This article will delve into the role of AI in Predictive Maintenance for Oil Rigs, with a special focus on how FAT FINGER, a digital workflow procedure builder, is contributing to this technological revolution.

Understanding Predictive Maintenance

Predictive Maintenance refers to the use of data-driven, proactive maintenance strategies that predict maintenance requirements for mechanical and operational systems. In the context of Oil Rigs, Predictive Maintenance can help prevent equipment failure, reduce downtime, and increase Operational Efficiency.

The Role of AI in Predictive Maintenance

AI plays a crucial role in Predictive Maintenance by analyzing vast amounts of data to predict equipment failures before they occur. Here are some ways AI contributes to Predictive Maintenance:

- Real-time Monitoring: AI systems can monitor equipment in real-time, identifying any anomalies or changes in performance that may indicate a potential failure.

- Data Analysis: AI can analyze vast amounts of data from various sources, including sensors, logs, and historical data, to identify patterns and trends that may indicate a potential problem.

- Predictive Analytics: Using Machine Learning algorithms, AI can predict potential failures based on the analyzed data, allowing for timely maintenance and prevention of costly downtime.

- Automated Reporting: AI can generate automated reports detailing the health of the equipment, potential issues, and recommended maintenance actions.

Case Study: AI in Action

A study by McKinsey & Company revealed that Oil Rigs using AI for Predictive Maintenance could reduce maintenance costs by 13%, extend the life of their equipment by years, and increase production by 10%. This is a clear indication of the transformative potential of AI in the oil and gas industry.

FAT FINGER and AI-Powered Predictive Maintenance

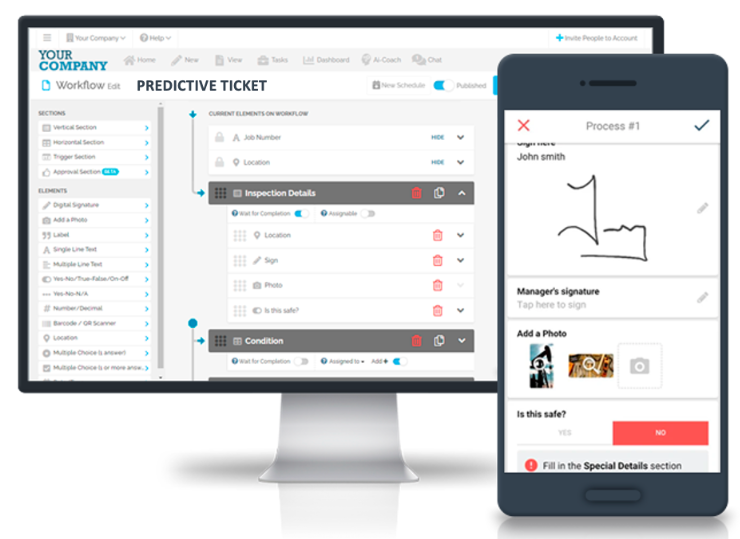

FAT FINGER is at the forefront of this AI revolution, providing a platform that empowers front-line teams to do their work correctly every time. FAT FINGER allows you to build checklists, workflows, and digital procedures that unlock operational excellence. Its features include a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and Artificial Intelligence coaching.

With FAT FINGER, oil rig operators can leverage AI to enhance their Predictive Maintenance strategies. The platform’s AI capabilities can analyze data from various sources, identify potential issues, and recommend maintenance actions. This not only helps prevent equipment failure but also enhances Operational Efficiency and safety.

Conclusion

The role of AI in Predictive Maintenance for Oil Rigs is transformative. By enabling Real-time Monitoring, comprehensive data analysis, predictive analytics, and automated reporting, AI can significantly enhance the efficiency and safety of oil rig operations. Platforms like FAT FINGER are leading the way in this AI revolution, providing tools that empower teams to leverage AI for Predictive Maintenance.

Are you ready to unlock the potential of AI for Predictive Maintenance in your oil rig operations? Sign up for FAT FINGER or request a demo today to learn how you can leverage AI to enhance your Operational Efficiency and safety.