As the global energy landscape continues to evolve, the integration of renewable energy sources in oil and gas operations has become a critical focus. This shift is driven by the increasing demand for cleaner energy, the need to reduce carbon emissions, and the potential for cost savings. In this context, digital workflow procedure builders like FAT FINGER are playing a pivotal role in facilitating this transition. FAT FINGER empowers front-line teams to do their work correctly every time, unlocking operational excellence through its comprehensive suite of features.

The Need for Renewable Energy in Oil and Gas Operations

The oil and gas industry is under increasing pressure to reduce its carbon footprint. This is due to a combination of regulatory requirements, public sentiment, and the economic potential of renewable energy sources. The integration of renewable energy can help the industry achieve these goals while also improving operational efficiency.

How Renewable Energy is Being Integrated

There are several ways in which renewable energy is being integrated into oil and gas operations. These include:

- Using solar or wind power to provide electricity for offshore platforms

- Replacing diesel generators with renewable energy sources

- Using renewable energy to power water treatment facilities

- Integrating renewable energy into the grid to reduce reliance on fossil fuels

The Role of Digital Workflow Procedure Builders

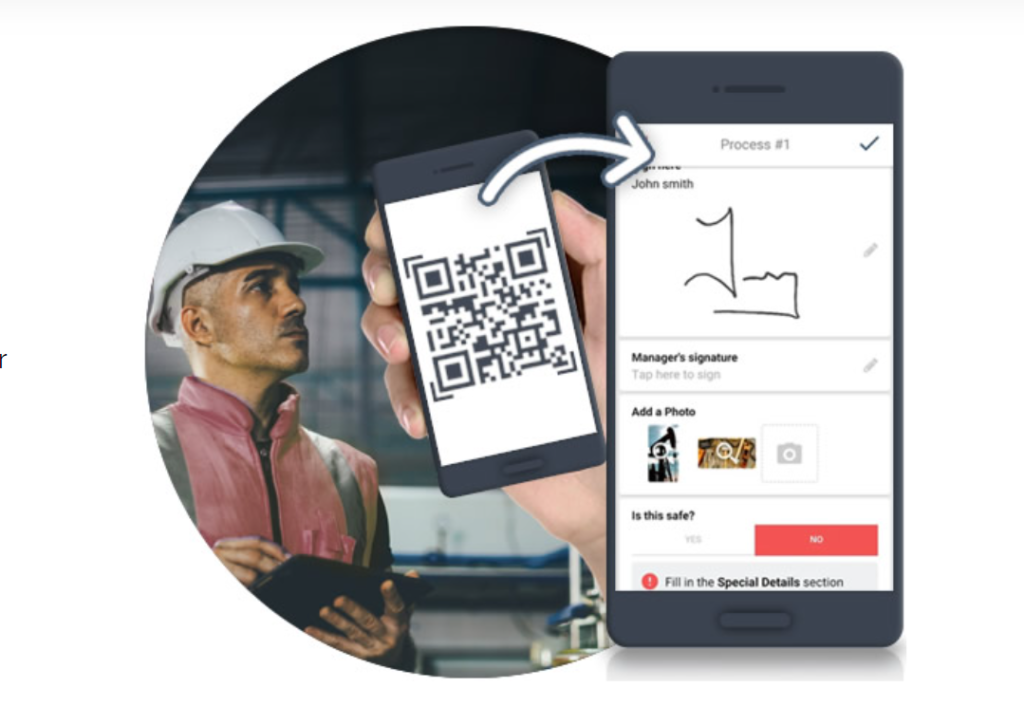

Digital workflow procedure builders like FAT FINGER are playing a crucial role in this transition. They allow companies to create checklists, workflows, and digital procedures that streamline operations and improve efficiency. This can be particularly beneficial when integrating renewable energy sources, as it can help to manage the complexities of this process.

Case Study: FAT FINGER in Action

One example of how FAT FINGER can support the integration of renewable energy is in the area of safety. The platform’s Take 5 Safety, Near Miss Reporting, and Incident Reporting features can be used to ensure that safety standards are maintained during the transition to renewable energy. Similarly, its Quality Control and Shift Handover features can help to manage operational changes.

Benefits of Using FAT FINGER

There are several benefits to using FAT FINGER in the integration of renewable energy sources. These include:

- Improved operational efficiency

- Reduced risk of errors

- Increased safety

- Ability to manage complex processes

- Real-time data and insights

Conclusion

The integration of renewable energy sources in oil and gas operations is a complex but necessary process. It requires careful planning, management, and oversight. Digital workflow procedure builders like FAT FINGER can play a crucial role in this transition, helping to streamline operations, reduce errors, and improve safety. With its comprehensive suite of features, FAT FINGER is well-positioned to support the oil and gas industry as it moves towards a more sustainable future.

If you’re interested in learning more about how FAT FINGER can support your operations, sign up today or request a demo.