As the manufacturing industry continues to evolve, the need for scalable solutions has become increasingly apparent. These solutions are essential for businesses to adapt to changing market demands, improve operational efficiency, and drive growth. One such solution that has proven to be a game-changer in the manufacturing industry is FAT FINGER, a digital workflow procedure builder that empowers front-line teams to do their work correctly every time.

Understanding Scalable Solutions

Scalable solutions are vital for businesses, especially in the manufacturing industry, as they provide the ability to accommodate and adapt to growth. The term ‘scalable’ refers to the capacity of a system, strategy, or process to handle increasing amounts of work or to be enlarged seamlessly. This concept is particularly relevant in the context of rapid business expansion or a significant increase in market demand for products.

In the context of manufacturing, scalability could mean several things. Firstly, it could refer to the ability to increase production capacity. This means the business has the capability to ramp up its manufacturing processes to produce more products as demand increases. A scalable solution in this scenario may involve automated manufacturing systems that can be expanded or enhanced, or the ability to easily introduce more production lines.

Secondly, scalable solutions might pertain to the streamlining of operations. As a business grows, it becomes more complex, and procedures that worked well when the company was smaller may become inefficient or unsustainable. A scalable solution in this case could involve implementing new management systems or operational processes that simplify tasks, reduce waste, or improve communication and coordination.

Thirdly, scalable solutions can also refer to the improvement of product quality as the business grows. Maintaining consistent quality during expansion can be challenging, but it’s crucial for maintaining a strong brand reputation. Scalable solutions here might include quality control systems that can handle larger production volumes, or training programs that ensure all staff members understand and adhere to quality standards.

In essence, scalable solutions in manufacturing are about preparing for growth and ensuring that the business can handle it effectively when it happens. These solutions help businesses stay efficient, maintain product quality, and meet increasing demand as they grow. The ability to scale is critical for businesses to remain competitive, adapt to market changes, and sustain long-term success.

Why Scalability Matters in Manufacturing

Scalability plays a crucial role in manufacturing for several reasons:

1. Increased Production Capacity: Scalability allows manufacturing companies to expand their production capabilities to meet increasing demand. If a manufacturing process is scalable, it can be ramped up quickly and efficiently, increasing output without a significant increase in costs.

2. Cost-Effective Operations: Scalability can help in reducing operational costs. When manufacturing processes are scalable, companies can produce larger quantities of a product at a lower cost per unit. This is because fixed costs such as machinery, facilities, and labor can be spread over a larger number of units, reducing the cost per unit.

3. Flexibility and Adaptability: Scalability provides flexibility and adaptability to changes in market demand. If demand suddenly increases, a scalable manufacturing process can ramp up production quickly. Conversely, if demand decreases, production can be scaled back, preventing wasted resources and excess inventory.

4. Competitive Advantage: Scalability can give a company a competitive edge. The ability to quickly and efficiently increase production can help companies respond more effectively to market changes, meet customer demand, and gain a larger market share.

5. Innovation and Growth: Scalability can also facilitate innovation and growth. By enabling companies to efficiently produce larger quantities of a product, scalability can free up resources that can be invested in research and development, leading to new products and services.

6. Sustainability: Scalable manufacturing processes can be more sustainable. They can lead to more efficient use of resources, less waste, and lower environmental impact. For instance, economies of scale can reduce energy consumption per unit of output.

7. Risk Management: Scalability can also play a crucial role in risk management in manufacturing. It allows companies to quickly adjust their production levels in response to external shocks such as sudden changes in market conditions or disruptions in supply chains, reducing the potential impact of these risks.

In conclusion, scalability is a key factor in the success and sustainability of manufacturing operations. It provides the flexibility and efficiency necessary to navigate market changes, manage risks, and drive growth and innovation.

Case Study: The Role of FAT FINGER in Manufacturing Scalability

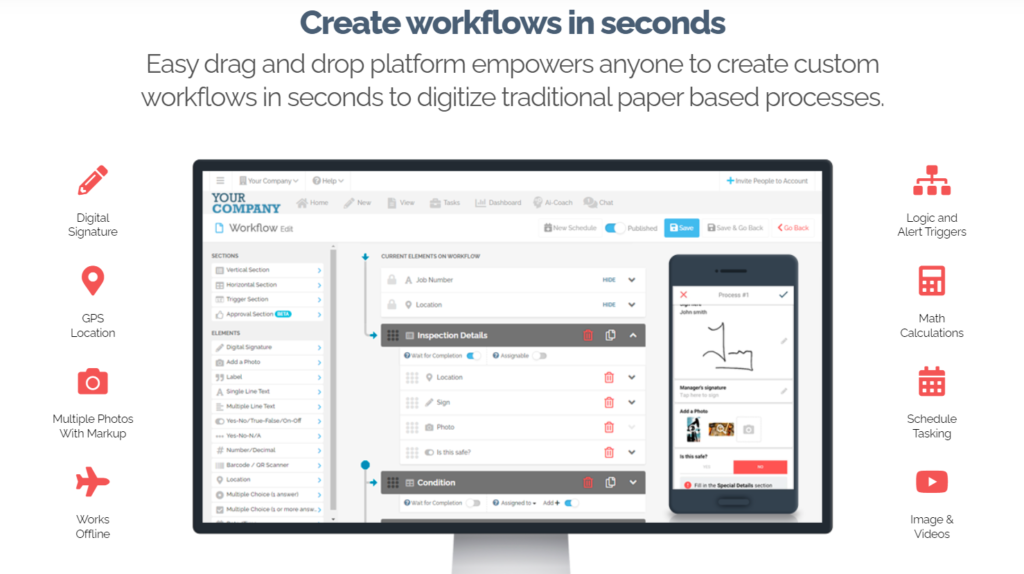

FAT FINGER is a prime example of a scalable solution that is driving growth in the manufacturing industry. This digital workflow procedure builder allows businesses to create checklists, workflows, and digital procedures that unlock operational excellence. With features like Drag & Drop Workflow Builder, Mobile & Desktop Workflows, Dashboards, Integrations, Augmented Reality, Connect IoT Devices, and Artificial Intelligence Coaching, FAT FINGER is revolutionizing the way manufacturing businesses operate.

For instance, a manufacturing company that previously relied on manual processes for quality control can use FAT FINGER to digitize these processes, making them more efficient and less prone to errors. As the company grows, these digital workflows can be easily scaled up to handle increased production volumes, ensuring consistent product quality and operational efficiency.

Statistics Highlighting the Importance of Scalability

According to a report by McKinsey, companies that prioritize scalability are 1.5 times more likely to achieve above-average growth in their industry. Furthermore, a study by Deloitte found that 85% of global manufacturing companies consider scalable solutions as a critical factor in their growth strategy.

Conclusion

Scalable solutions are no longer a luxury but a necessity in the manufacturing industry. They provide the flexibility and efficiency needed to adapt to changing market conditions, drive operational excellence, and foster growth. FAT FINGER, with its robust features and user-friendly interface, is leading the way in providing scalable solutions for the manufacturing industry. By leveraging such solutions, manufacturing businesses can position themselves for sustained success in an increasingly competitive market.

Ready to unlock the potential of scalable solutions for your manufacturing business? Sign up for FAT FINGER or request a demo today to see how our digital workflow procedure builder can empower your front-line teams and drive operational excellence.