In the era of Industry 4.0, Digital Transformation is revolutionizing every aspect of industrial operations, from supply chain management to customer service. One area where this transformation is particularly evident is in Facility Inspections and Production Rounds. With the advent of digital tools like FAT FINGER, a digital workflow procedure builder, the way these essential tasks are conducted is changing dramatically, leading to increased efficiency, accuracy, and safety.

Traditional vs. Digital: A Paradigm Shift in Facility Inspections and Production Rounds

Traditionally, Facility Inspections and Production Rounds have been manual, paper-based processes. Inspectors would physically walk around the facility, checking equipment and processes against a checklist, and then manually record their findings. This method, while functional, is time-consuming, prone to human error, and offers limited visibility into real-time operations.

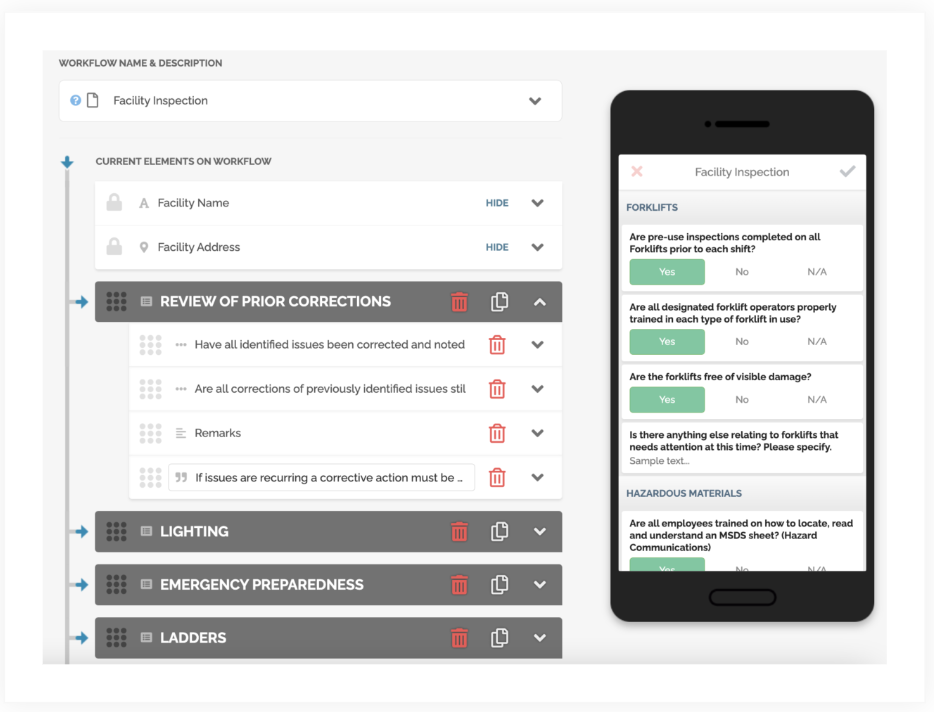

Enter Digital Transformation. With tools like FAT FINGER, these processes can now be automated and digitized. FAT FINGER allows front-line teams to build checklists, workflows, and digital procedures that ensure work is done correctly every time. This not only streamlines the inspection process but also provides real-time data that can be used to make informed decisions and drive Operational Excellence.

Key Benefits of Digital Transformation in Facility Inspections and Production Rounds

Digital Transformation offers several key benefits in the context of Facility Inspections and Production Rounds:

- Increased Efficiency: Digital tools automate many of the manual tasks associated with inspections, such as data entry and report generation, freeing up inspectors to focus on more value-added activities.

- Improved Accuracy: By eliminating the need for manual data entry, digital tools reduce the risk of human error, leading to more accurate and reliable data.

- Enhanced Safety: Real-time data and alerts can help identify potential safety issues before they become serious, reducing the risk of accidents and injuries.

- Better Decision Making: With access to real-time data, managers can make informed decisions based on current conditions, rather than relying on outdated reports.

Case Study: The Power of FAT FINGER in Action

To illustrate the impact of Digital Transformation on Facility Inspections and Production Rounds, let’s look at a real-world example. A large manufacturing company was struggling with inefficient, paper-based inspections that were leading to frequent equipment failures and costly downtime. After implementing FAT FINGER, the company was able to automate their inspection processes, leading to a 30% reduction in equipment failures and a significant increase in operational efficiency.

With FAT FINGER’s drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and artificial intelligence coaching, the company was able to transform their inspection processes, leading to improved productivity, safety, and bottom-line results.

Conclusion: Embracing Digital Transformation in Facility Inspections and Production Rounds

The Digital Transformation of Facility Inspections and Production Rounds is not just a trend, but a necessity in today’s fast-paced, data-driven industrial environment. By leveraging digital tools like FAT FINGER, companies can streamline their inspection processes, improve accuracy and safety, and make better, data-driven decisions.

As the case study above illustrates, the benefits of Digital Transformation in this area are clear. But to fully realize these benefits, companies must be willing to embrace change and invest in the right tools and technologies.

Are you ready to take your Facility Inspections and Production Rounds to the next level? Sign up for FAT FINGER or request a demo today to see how our digital workflow procedure builder can empower your front-line teams and unlock Operational Excellence.