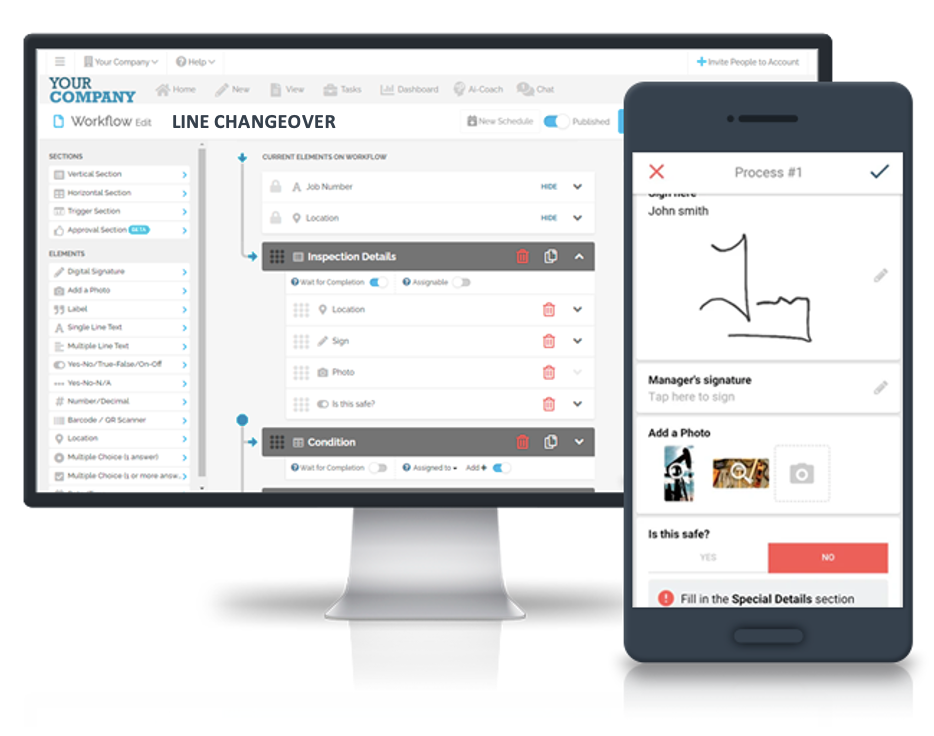

In the fast-paced world of manufacturing, the role of supply chain partnerships in smoothing line changeovers cannot be overstated. As production managers strive to reduce downtime, improve line efficiency, and increase product quality, the need for effective line clearance procedures becomes paramount. This is where FAT FINGER comes into play. FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. With its drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and artificial intelligence coaching, FAT FINGER is revolutionizing the way line changeovers are managed. Request a demo today to see how FAT FINGER can streamline your production line clearance process.

The Importance of Supply Chain Partnerships

Supply chain partnerships play a crucial role in the manufacturing industry. They facilitate the smooth transition of goods from one stage of production to another, ensuring that all components are available when needed. This is particularly important during line changeovers, where any delay can result in significant downtime and loss of productivity.

How FAT FINGER Facilitates Smooth Line Changeovers

With FAT FINGER, you can build digital line clearance procedures that facilitate seamless line changeovers. The software allows you to verify that all Line Changeover activities have been completed and that the line is ready to resume production. This reduces downtime, improves line efficiency, and increases product quality. As one production manager puts it, “FAT FINGER is a game changer for our production line clearance process. We can now streamline our production lines with confidence knowing that everything is right at our fingertips.”

Benefits of Using FAT FINGER for Line Changeovers

- Reduced Downtime: By ensuring that all line changeover activities are completed, FAT FINGER helps to minimize downtime and keep production lines running smoothly.

- Improved Line Efficiency: FAT FINGER’s digital workflows allow for a more efficient line clearance process, resulting in improved line efficiency.

- Increased Product Quality: With FAT FINGER, you can ensure that all line changeover activities are completed correctly, leading to increased product quality.

Conclusion

In conclusion, supply chain partnerships play a crucial role in smoothing line changeovers in the manufacturing industry. By leveraging the power of FAT FINGER’s digital workflow procedure builder, production managers can streamline their line clearance processes, reduce downtime, improve line efficiency, and increase product quality. Don’t let line changeovers be a bottleneck in your production process. Sign up for FAT FINGER today and unlock operational excellence in your manufacturing operations.

Discover the crucial role of supply chain partnerships in smoothing line changeovers. Learn how these partnerships can enhance efficiency, reduce downtime, and increase profitability. Visit here to delve deeper into this topic.