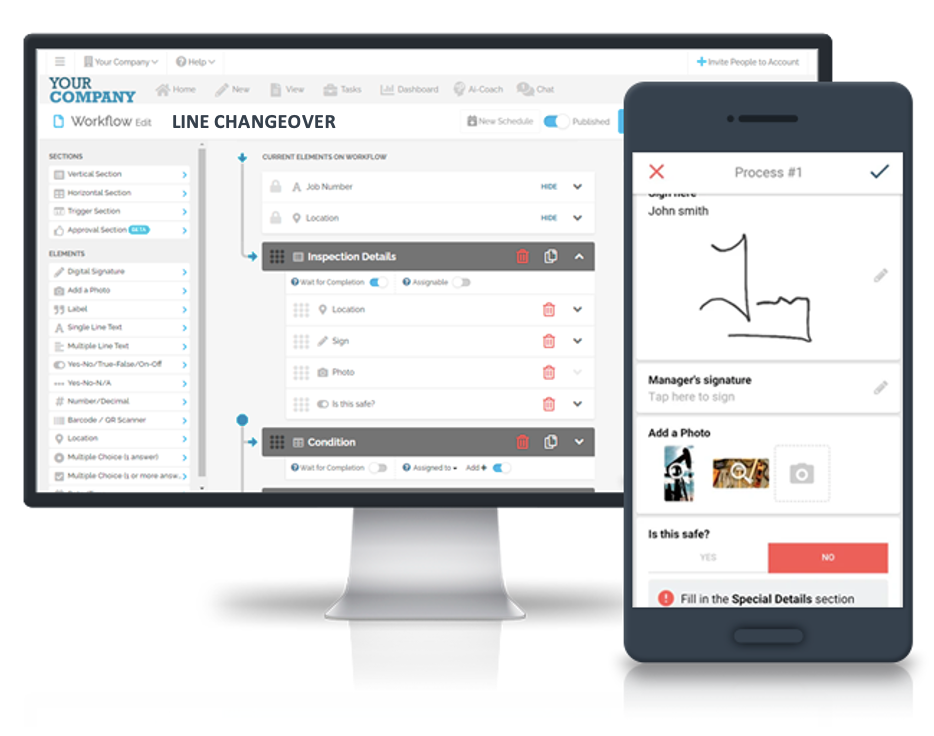

As the world of manufacturing continues to evolve, the need for seamless line changeovers has never been more critical. The key to achieving this lies in effective supply chain coordination. This is where FAT FINGER comes into play. FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. With features like Drag & Drop Workflow Builder, Mobile & Desktop Workflows, Dashboards, Integrations, Augmented Reality, Connect IoT Devices, and Artificial Intelligence Coaching, FAT FINGER is revolutionizing the way businesses operate. Production Managers have hailed FAT FINGER as a game changer for their production line clearance process. Request a demo today and see how FAT FINGER can streamline your production lines.

Understanding Supply Chain Coordination

Supply chain coordination is the process of integrating various parts of the supply chain to ensure smooth operations. It involves aligning the objectives and actions of different players in the supply chain to achieve optimal performance. This coordination is crucial during line changeovers, a process that verifies that all Line Changeover activities have been completed and that the line is ready to resume production.

The Importance of Seamless Line Changeovers

Seamless line changeovers are vital for several reasons:

- Reduced downtime: Efficient line changeovers minimize production downtime, leading to increased productivity.

- Improved line efficiency: Seamless changeovers ensure that production lines are always operating at their maximum capacity.

- Increased product quality: With a well-coordinated changeover process, the risk of errors and defects is significantly reduced, leading to improved product quality.

How FAT FINGER Facilitates Seamless Line Changeovers

FAT FINGER plays a pivotal role in facilitating seamless line changeovers. With its digital line clearance procedures, FAT FINGER ensures that all line changeover activities are completed efficiently and accurately. This not only reduces downtime but also improves line efficiency and product quality.

Drag & Drop Workflow Builder

The Drag & Drop Workflow Builder allows you to create custom workflows that suit your specific line changeover needs. This ensures that all necessary steps are followed, reducing the risk of errors and oversights.

Mobile & Desktop Workflows

With FAT FINGER, you can access your workflows on both mobile and desktop platforms. This means you can monitor and manage your line changeovers from anywhere, at any time.

Artificial Intelligence Coaching

FAT FINGER’s Artificial Intelligence Coaching feature provides real-time guidance to your team during the line changeover process. This ensures that all procedures are followed correctly, leading to seamless line changeovers.

Conclusion

In conclusion, effective supply chain coordination is crucial for seamless line changeovers. With FAT FINGER’s innovative features, you can streamline your line changeover process, reduce downtime, improve line efficiency, and increase product quality. As one Production Manager put it, “FAT FINGER is a game changer for our production line clearance process. We can now streamline our production lines with confidence knowing that everything is right at our fingertips.” Don’t miss out on the opportunity to revolutionize your line changeover process. Sign up for FAT FINGER today and unlock operational excellence.

Take the first step towards seamless line changeovers in your supply chain coordination. Visit FatFinger to learn more about how our solutions can streamline your operations. Don’t wait, optimize your supply chain today!