Inspections are a critical part of maintaining the safety, efficiency, and longevity of any operation. Whether it’s a manufacturing plant, a construction site, or a fleet of vehicles, regular inspections ensure that everything is running smoothly and safely.

However, the inspection process can be complex and time-consuming. That’s where FAT FINGER comes in. With its digital workflows, FAT FINGER simplifies the inspection process, making it more efficient and effective. Let’s take a closer look at the different stages of the inspection process and how FAT FINGER can help.

But before we do, request a demo below.

Stage 1: Pre-Inspection Planning

The first stage of any inspection process is planning. This involves identifying what needs to be inspected, setting the criteria for inspection, and scheduling the inspection. It’s crucial to be thorough in this stage to ensure that nothing is overlooked during the actual inspection.

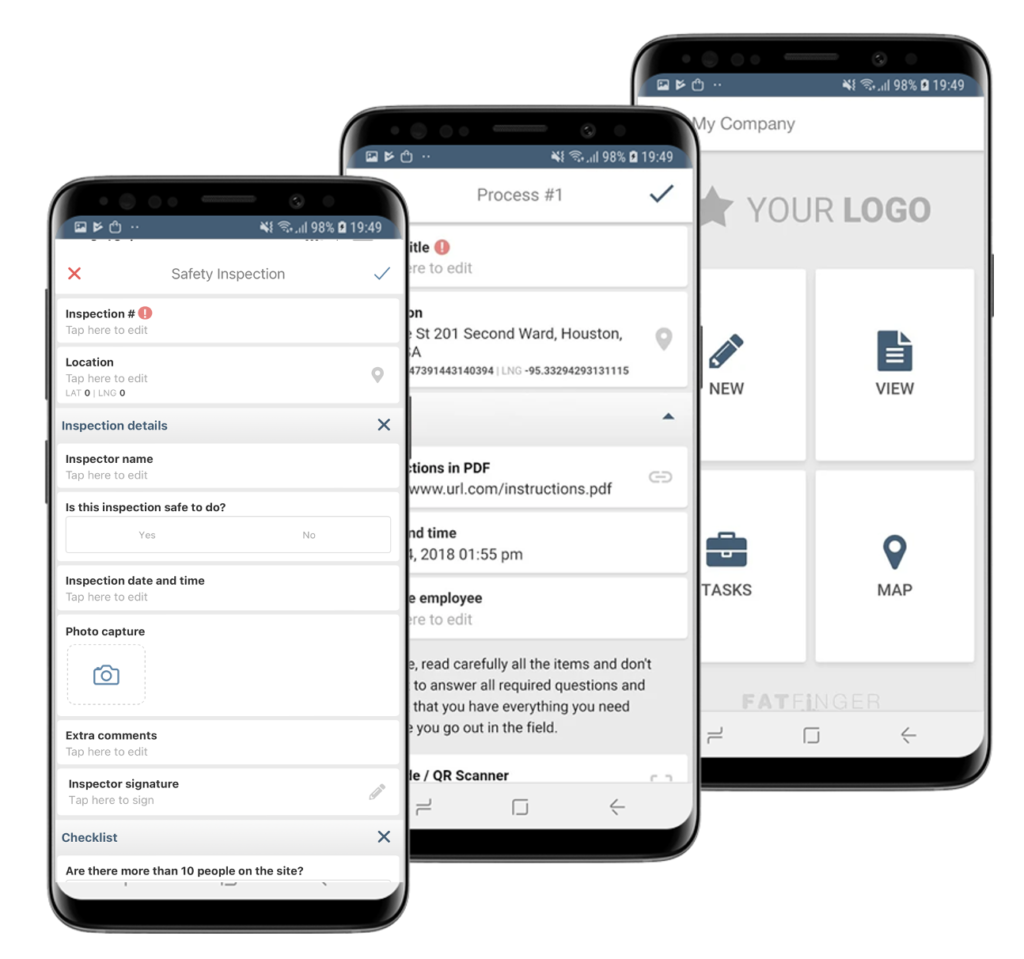

With FAT FINGER, you can easily create a mobile asset inspection workflow that outlines exactly what needs to be inspected and when. This not only ensures that nothing is missed, but also saves time and resources by streamlining the planning process.

Stage 2: Conducting the Inspection

The next stage is the actual inspection. This involves physically examining the asset or area to be inspected and checking it against the criteria set in the planning stage. Depending on the nature of the inspection, this could involve a variety of tasks, from visual inspections to functional tests.

FAT FINGER’s digital workflows make this stage easier and more efficient. With its easy-to-use interface, inspectors can quickly and accurately record their findings, reducing the risk of errors and oversights. Plus, with its real-time data capture, FAT FINGER allows for immediate action if any issues are identified.

Stage 3: Post-Inspection Review

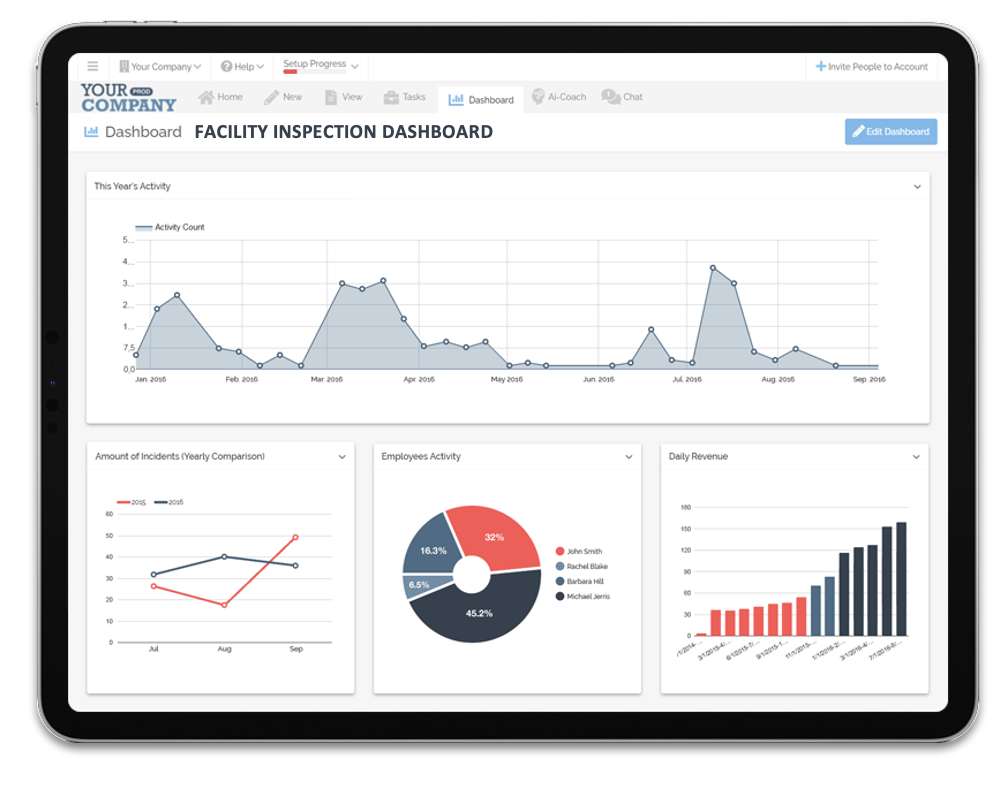

Once the inspection is complete, the findings need to be reviewed and analyzed. This involves comparing the results of the inspection against the set criteria and identifying any areas of concern. This stage is crucial for identifying potential issues before they become major problems.

With FAT FINGER, this stage is simplified. The platform automatically compiles and analyzes the inspection data, providing clear, easy-to-understand reports. This not only saves time but also ensures that the data is accurate and reliable.

Stage 4: Taking Corrective Action

The final stage of the inspection process is taking corrective action. This involves addressing any issues identified during the inspection and implementing measures to prevent them from recurring. This could involve anything from minor repairs to major overhauls.

Again, FAT FINGER simplifies this stage. With its real-time data capture and automatic reporting, FAT FINGER allows for immediate action to be taken. Plus, its digital workflows can be easily updated to reflect any changes in procedures or standards, ensuring that future inspections are even more effective.

Conclusion

The inspection process is a crucial part of maintaining safety and efficiency in any operation. However, it can be complex and time-consuming. With FAT FINGER’s digital workflows, the process is simplified and streamlined, making it more efficient and effective.

From pre-inspection planning to taking corrective action, FAT FINGER has you covered. So why not create a mobile asset inspection workflow for free on FAT FINGER today?