As the world continues to grapple with the challenges of energy consumption and sustainability, industrial facilities are increasingly turning to smart technology to optimize their operations. One such technology is the use of smart meters and sensors for energy consumption analysis. This article explores how these devices are revolutionizing energy management in industrial facilities, with a particular focus on the role of FAT FINGER, a digital workflow procedure builder that empowers front-line teams to do their work correctly every time.

Ready to transform your facility’s energy management? Request a demo of FAT FINGER today.

Understanding Smart Meters and Sensors

Smart meters and sensors are devices that collect detailed energy consumption data in real-time. They provide valuable insights into energy usage patterns, enabling facility managers to identify inefficiencies and implement energy-saving measures.

Benefits of Smart Meters and Sensors

- Real-time energy consumption data

- Improved energy efficiency

- Reduced energy costs

- Enhanced sustainability

The Role of FAT FINGER in Energy Consumption Analysis

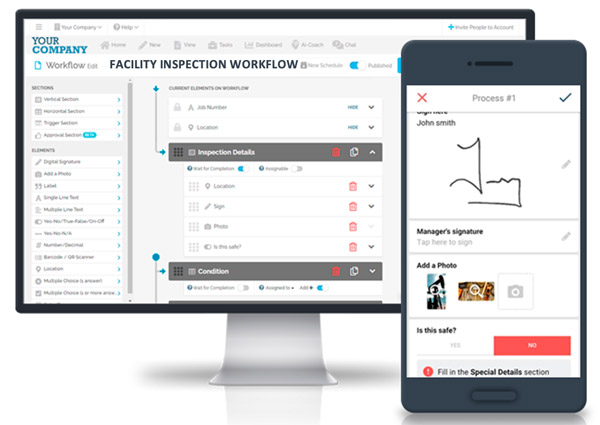

FAT FINGER is a digital workflow procedure builder that allows you to create checklists, workflows, and digital procedures to unlock operational excellence. With features like a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and artificial intelligence coaching, FAT FINGER is a powerful tool for energy consumption analysis in industrial facilities.

Facility Inspection / Production Rounds with FAT FINGER

Facility inspections are a critical part of maintaining a safe and functional facility. With FAT FINGER, you can build digital workflow procedures for facility inspections and production rounds, ensuring that your facility remains in good condition and avoiding costly repairs or downtime.

Case Study: Smart Meters and Sensors in Action

Consider the case of a large manufacturing facility that implemented smart meters and sensors to monitor its energy consumption. By integrating these devices with FAT FINGER, the facility was able to identify areas of energy waste, implement energy-saving measures, and reduce its energy costs by 20% within the first year.

Conclusion

Smart meters and sensors are transforming energy management in industrial facilities, providing real-time data that enables facility managers to optimize energy usage and reduce costs. By integrating these devices with a digital workflow procedure builder like FAT FINGER, facilities can unlock even greater operational excellence.

Ready to take your facility’s energy management to the next level? Sign up for FAT FINGER today.

Discover how Smart Meters and Sensors can revolutionize your Energy Consumption Analysis in Industrial Facilities. Make the smart switch today and optimize your energy usage for better efficiency and cost savings. Learn more at fatfinger.io. Take control of your energy consumption now!