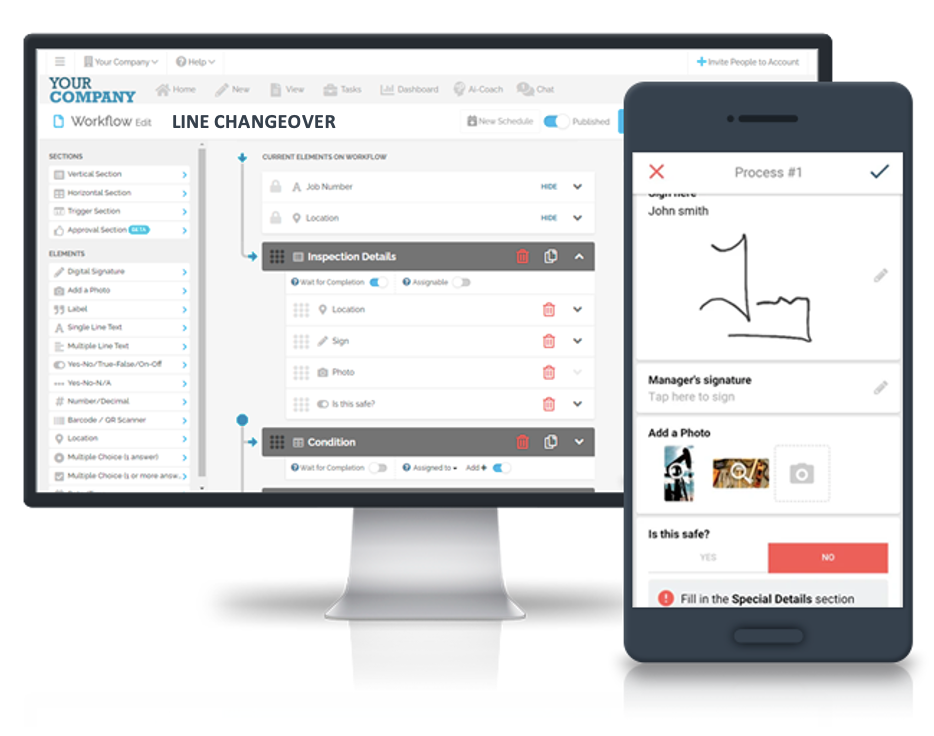

Line changeovers in High-Risk Environments are critical operations that require meticulous planning, execution, and verification. Ensuring Safety during these operations is paramount. This is where FAT FINGER comes into play. FAT FINGER is a digital workflow procedure builder that empowers front-line teams to perform their work correctly every time. With its drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and artificial intelligence coaching, FAT FINGER allows you to build digital line clearance procedures to facilitate seamless line changeovers. Request a demo today to see how FAT FINGER can revolutionize your Line Changeover process.

Safety Protocols for Line Changeovers

Line changeovers, or line clearances, are processes that verify all Line Changeover activities have been completed and that the line is ready to resume production. The benefits of line clearance include reduced downtime, improved line efficiency, and increased product quality. However, these operations can be high-risk if not properly managed. Here are some Safety protocols that can be implemented:

- Thorough planning and preparation

- Clear communication among team members

- Regular training and drills

- Use of appropriate personal protective equipment (PPE)

- Implementation of digital workflow procedures like FAT FINGER

The Role of FAT FINGER in Line Changeovers

FAT FINGER plays a crucial role in ensuring Safety during line changeovers. Its features allow for the creation of digital line clearance procedures, which can significantly reduce the risk of errors and accidents. Here’s how:

- Drag & Drop Workflow Builder: This feature allows you to create custom workflows that suit your specific Line Changeover needs.

- Mobile & Desktop Workflows: FAT FINGER’s workflows can be accessed on both mobile and desktop devices, ensuring that your team can follow the procedures wherever they are.

- Artificial Intelligence Coaching: FAT FINGER’s AI coaching can guide your team through the Line Changeover process, reducing the risk of human error.

Conclusion

Ensuring Safety during line changeovers in High-Risk Environments is a complex task that requires careful planning, clear communication, regular training, and the use of appropriate tools. FAT FINGER, with its comprehensive features, can significantly enhance the Safety and efficiency of your Line Changeover process. By implementing digital line clearance procedures, you can reduce downtime, improve line efficiency, and increase product quality. As one Production Manager put it, “FAT FINGER is a game changer for our production line clearance process.” Don’t miss out on the opportunity to revolutionize your Line Changeover process. Sign up for FAT FINGER today.

Learn more about the essential Safety Protocols for Line Changeovers in High-Risk Environments. Ensure the safety of your team and the efficiency of your operations. Visit here for more information.