As the oil and gas industry continues to evolve, so does the complexity of managing risks associated with its operations. The industry is fraught with potential hazards, from environmental impacts to worker safety, making risk management a top priority. This is where FAT FINGER comes into play.

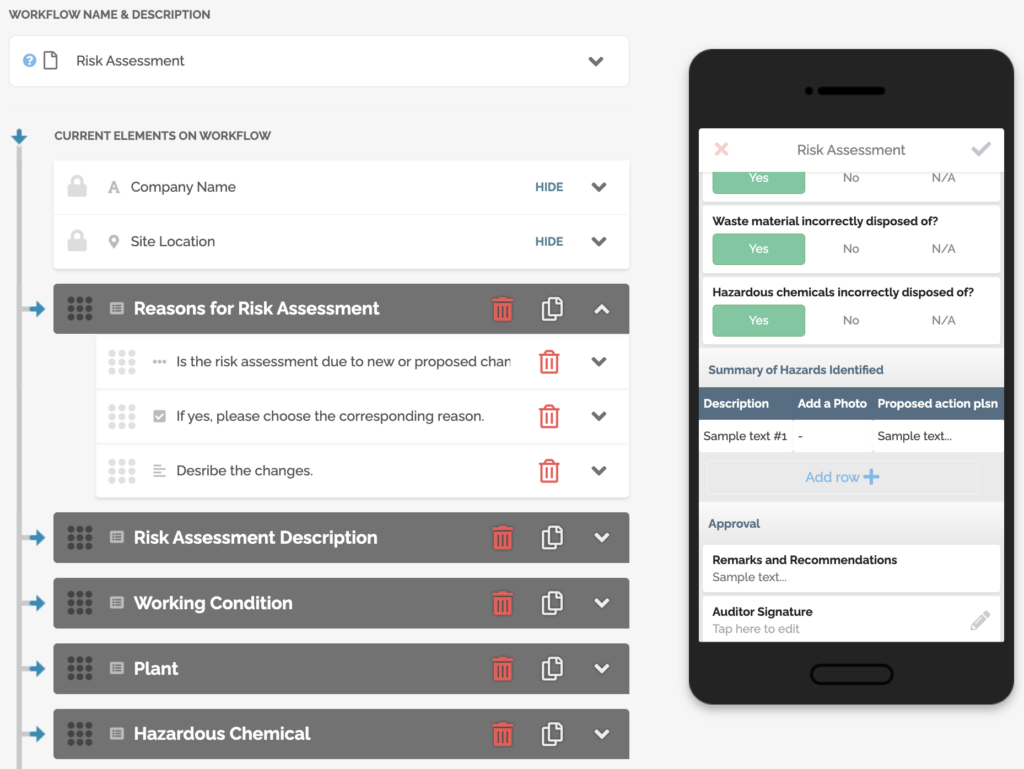

FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. With FAT FINGER, you can build digital workflow procedures to improve Risk Assessment and manage risks in your facility. Request a demo today to see how FAT FINGER can help safeguard your company from threats.

Understanding Risk Management in the Oil and Gas Industry

Risk management in the oil and gas industry involves identifying, assessing, and prioritizing risks, followed by applying resources to minimize, monitor, and control the probability or impact of unfortunate events. It’s a continuous, proactive, and systematic process to understand, manage, and communicate risk from an organization-wide perspective.

Key Risks in the Oil and Gas Industry

The oil and gas industry faces a myriad of risks, including:

- Operational risks: These include equipment failure, process disruption, and safety hazards.

- Environmental risks: These encompass spills, leaks, and other environmental damage.

- Regulatory risks: These involve non-compliance with industry regulations and standards.

- Market risks: These include fluctuations in oil and gas prices, exchange rates, and interest rates.

How FAT FINGER Enhances Risk Management

FAT FINGER’s digital workflow procedure builder allows you to create checklists, workflows, and digital procedures that unlock operational excellence. Here’s how FAT FINGER enhances risk management:

Intuitive Digital Workflow

Every site has its own potential hazards. With FAT FINGER, you can import different safety processes and make them your own, or simply create one from scratch. Once you’re done, you can export your safety workflow to all of your different sites, ensuring a paperless and risk-free operation.

Real-Time Risk Assessment

FAT FINGER’s mobile and desktop workflows allow for real-time risk assessment. You can monitor operations, identify potential risks, and take immediate action to mitigate them.

Compliance with Regulations

FAT FINGER’s digital procedures ensure compliance with industry regulations and standards, reducing the risk of non-compliance and associated penalties.

Integration with IoT Devices

FAT FINGER can connect with IoT devices, providing real-time data that can be used to identify and manage risks.

Case Study: Improving Safety with FAT FINGER

One oil and gas company used FAT FINGER to improve its safety procedures. The company was able to create a digital safety checklist that was accessible to all employees, ensuring that safety procedures were followed consistently. As a result, the company saw a significant reduction in safety incidents and an improvement in overall operational efficiency.

Conclusion

Risk management is a critical aspect of the oil and gas industry. With FAT FINGER, companies can effectively identify, assess, and manage risks, ensuring operational excellence and compliance with industry standards. By leveraging FAT FINGER’s digital workflow procedure builder, companies can create a safer, more efficient, and more profitable operation. Sign up for free today to see how FAT FINGER can enhance your risk management efforts.

Discover the essentials of Risk Management in the Oil and Gas Industry. Learn how to navigate the complexities and mitigate potential risks in this volatile sector. Don’t wait, Request a Demo today and take the first step towards mastering risk management in the oil and gas industry.