Manufacturing operations are fraught with risks that can lead to accidents, production delays, and financial losses. To mitigate these risks, it’s crucial to integrate Risk Assessment and management into your operations. One effective way to achieve this is by leveraging digital workflow procedure builders like FAT FINGER.

This innovative software empowers front-line teams to perform their work correctly every time, thereby reducing the risk of errors and accidents. Request a demo today to see how FAT FINGER can transform your manufacturing operations.

Understanding the Importance of Risk Assessment and Management in Manufacturing

Risk assessment and management are integral components of any manufacturing operation. They involve identifying potential hazards, evaluating their potential impact, and implementing measures to mitigate them. Without proper risk assessment and management, manufacturing operations can face severe consequences, including worker injuries, equipment damage, production delays, and financial losses.

How FAT FINGER Enhances Risk Assessment and Management

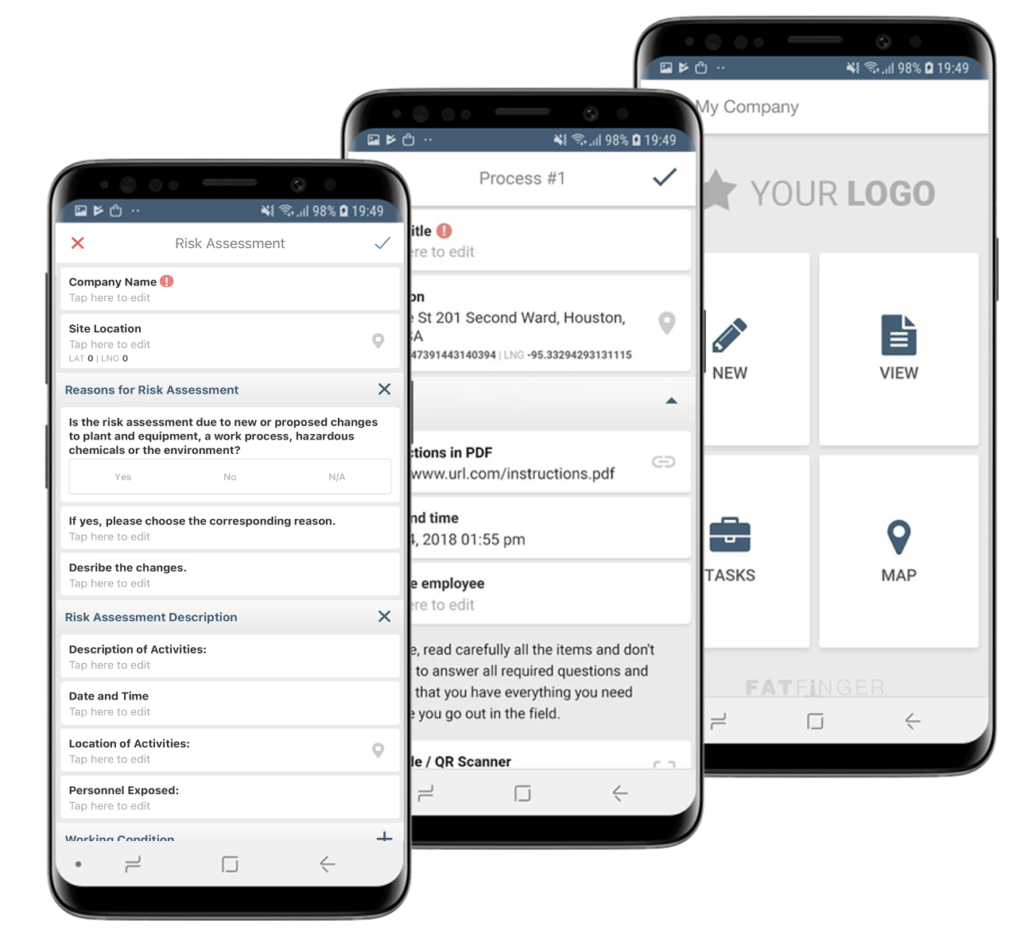

FAT FINGER is a digital workflow procedure builder that allows you to create checklists, workflows, and digital procedures to enhance operational excellence. Here’s how FAT FINGER can improve risk assessment and management in your manufacturing operations:

- Drag & Drop Workflow Builder: This feature allows you to easily create and modify workflows to suit your specific operational needs. You can incorporate risk assessment and management procedures into these workflows to ensure they are followed consistently.

- Mobile & Desktop Workflows: FAT FINGER’s workflows can be accessed on both mobile and desktop devices, ensuring that your team can perform risk assessments and implement risk management procedures wherever they are.

- Integrations: FAT FINGER can be integrated with other systems in your manufacturing operation, allowing for seamless data sharing and collaboration.

- Augmented Reality: This feature can be used to provide visual guidance during risk assessments, making the process more efficient and accurate.

- Connect IoT Devices: By connecting IoT devices, you can gather real-time data about your operations, which can be used to identify potential risks and implement preventive measures.

- Artificial Intelligence Coaching: This feature provides guidance and support to your team, helping them perform risk assessments and implement risk management procedures effectively.

Creating a Risk-Free Environment with FAT FINGER

With FAT FINGER, you can create a risk-free environment in your manufacturing operation. By building digital workflow procedures, you can make safety and preventive measures everyone’s responsibility. Risk Assessment Checklists built with FAT FINGER help you safeguard your company from threats. Every site has its potential hazards. In FAT FINGER, you can import different safety processes and make them your own, or simply create one from scratch. Once you’re done, you can export your safety workflow to all of your different sites, ensuring consistent safety practices across your operation.

Conclusion

Integrating risk assessment and management into manufacturing operations is crucial for preventing accidents, ensuring worker safety, and maintaining operational efficiency. With FAT FINGER, you can easily incorporate these processes into your operations, creating a safer, more efficient working environment. Don’t wait for an accident to happen before taking action.

Sign up for free today and see how FAT FINGER can help you manage risks in your manufacturing operation.

Don’t let uncertainties hinder your manufacturing operations. Integrate risk assessment and management today to ensure smooth and efficient operations. Learn how you can mitigate risks and optimize your manufacturing processes. Request a demo now.