In the manufacturing industry, risk analysis and assessment are critical components of operational excellence. These processes help identify potential hazards, evaluate their impact, and develop strategies to mitigate them. In this digital age, tools like FAT FINGER, a digital workflow procedure builder, are revolutionizing these processes.

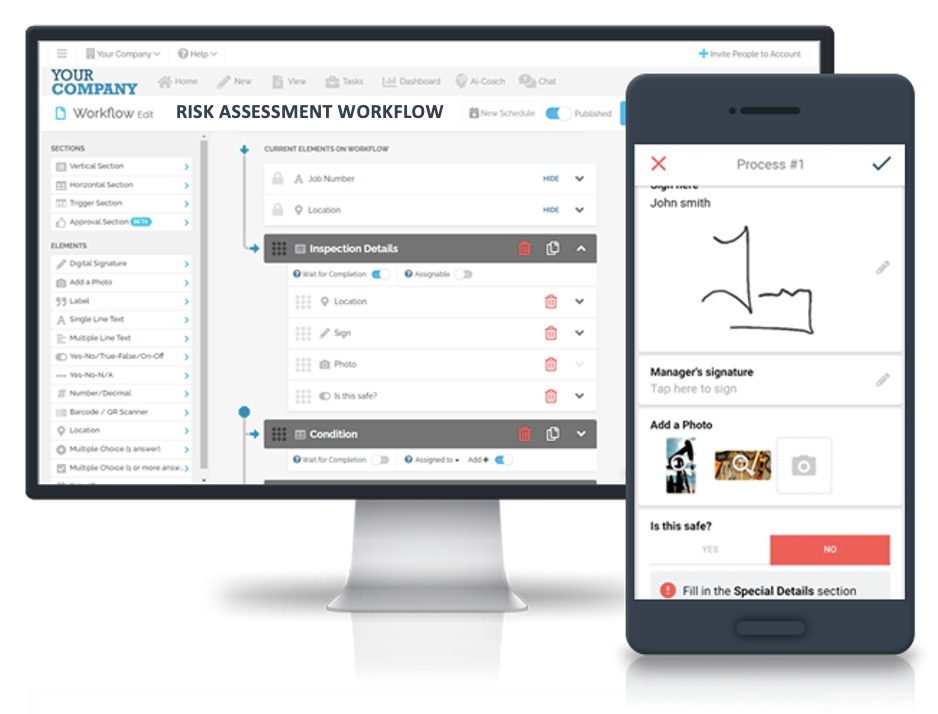

With features like Drag & Drop Workflow Builder, Mobile & Desktop Workflows, Dashboards, Integrations, Augmented Reality, Connect IoT Devices, and Artificial Intelligence Coaching, FAT FINGER allows you to build digital workflow to improve Risk Assessment and manage risks in your facility.

Request a demo today to see how FAT FINGER can transform your risk management strategies.

Risk Analysis vs Risk Assessment: Understanding the Difference

Risk analysis and risk assessment, while often used interchangeably, have distinct roles in the risk management process. Risk assessment is a broad process that identifies and evaluates potential risks. It involves identifying hazards, determining who might be harmed and how, evaluating risks, and deciding on precautions. On the other hand, risk analysis is a more in-depth process that quantifies the potential impact of identified risks and helps in making informed decisions.

Key Strategies for Risk Analysis and Assessment in Manufacturing

1. Comprehensive Hazard Identification

Identifying potential hazards is the first step in both risk analysis and assessment. This involves a thorough examination of the manufacturing process, equipment, and work environment. With FAT FINGER, you can import different safety processes and make them your own, or simply create one from scratch.

2. Detailed Risk Evaluation

Once hazards are identified, the next step is to evaluate their potential impact. This involves determining the likelihood of the risk occurring and the severity of its impact. FAT FINGER’s intuitive digital workflows make this process seamless and efficient.

3. Development of Mitigation Strategies

After evaluating the risks, the next step is to develop strategies to mitigate them. This could involve redesigning the manufacturing process, implementing safety measures, or training employees. FAT FINGER’s digital procedures can help ensure that these strategies are implemented correctly every time.

4. Regular Review and Update of Risk Assessment

Risk assessment is not a one-time process. It should be regularly reviewed and updated to account for changes in the manufacturing process, equipment, or work environment. FAT FINGER’s dashboards and integrations make it easy to monitor and update your risk assessments.

Case Study: How FAT FINGER Improved Risk Assessment in a Manufacturing Facility

A manufacturing facility was struggling with outdated and inefficient risk assessment processes. They turned to FAT FINGER to digitize their procedures. With FAT FINGER, they were able to create a comprehensive risk assessment checklist that was easy to update and monitor. This resulted in a significant reduction in workplace accidents and improved operational efficiency.

Conclusion

Risk analysis and assessment are critical components of operational excellence in the manufacturing industry. With tools like FAT FINGER, these processes can be streamlined and made more efficient. FAT FINGER’s digital workflow procedure builder allows you to create comprehensive risk assessment checklists, making safety and preventive measures everyone’s responsibility.

Sign up for free today to see how FAT FINGER can transform your risk management strategies.

Discover the key strategies for Risk Analysis vs Assessment in Manufacturing. Understand the difference and how each can impact your business. Don’t leave your manufacturing process to chance. Request a demo today and take the first step towards a more secure and efficient operation.