Industrial manufacturing is a sector fraught with numerous risks, from equipment malfunctions to human errors. These risks can lead to costly downtime, injuries, and even fatalities if not properly managed. This is where advanced Risk Assessment Techniques come into play, and where FAT FINGER, a digital workflow procedure builder, can be a game-changer. FAT FINGER empowers front-line teams to do their work correctly every time, unlocking operational excellence and significantly reducing risks.

Request a demo today to see how FAT FINGER can revolutionize your Risk Assessment process.

Understanding Risk Assessment in Industrial Manufacturing

Risk assessment is a systematic process of identifying potential hazards, evaluating the risks associated with these hazards, and determining appropriate ways to eliminate or control these risks. It is a critical component of any industrial manufacturing operation, as it helps to ensure the safety of employees and the smooth running of operations.

Advanced Techniques for Risk Assessment

While traditional risk assessment methods have their merits, advanced techniques offer more comprehensive and accurate results. These techniques include:

- Quantitative Risk Assessment (QRA): This technique uses numerical values to estimate the probability and impact of risks.

- Failure Mode and Effects Analysis (FMEA): FMEA identifies potential failure modes, their causes, and effects on the system or process.

- Monte Carlo Simulation: This technique uses probability distributions and random sampling to estimate risk.

The Role of FAT FINGER in Risk Assessment

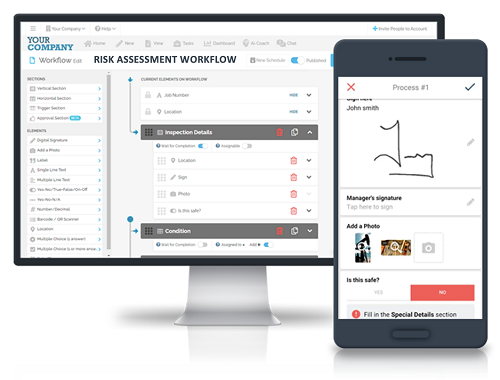

FAT FINGER plays a crucial role in risk assessment by allowing you to build digital workflow procedures that improve risk management. With features like Drag & Drop Workflow Builder, Mobile & Desktop Workflows, Dashboards, Integrations, Augmented Reality, Connect IoT Devices, and Artificial Intelligence Coaching, FAT FINGER makes safety and preventive measures everyone’s responsibility.

Risk Assessment Checklists built with FAT FINGER help you to safeguard your company from threats. The intuitive digital workflow is paperless and risk-free. Every site has its own potential hazards. In FAT FINGER, you can import different safety processes and make them your own, or simply create one from scratch. Once you’re done, you can export your safety workflow to all of your different sites.

Case Study: FAT FINGER in Action

Consider the case of a large manufacturing company that implemented FAT FINGER’s digital workflow procedures. The company was able to reduce equipment malfunctions by 30% and human errors by 40%, leading to a significant increase in operational efficiency and safety. This case study demonstrates the power of FAT FINGER in transforming risk assessment and management in industrial manufacturing.

Conclusion

Advanced Risk Assessment Techniques are essential for managing risks in industrial manufacturing. These techniques, coupled with the power of FAT FINGER’s digital workflow procedures, can significantly reduce risks and improve operational efficiency. By making safety and preventive measures everyone’s responsibility, FAT FINGER helps to create a safer and more productive work environment.

Sign up for a free trial or request a demo today to see how FAT FINGER can revolutionize your risk assessment process.

Discover the power of advanced techniques for risk assessment in industrial manufacturing. Enhance your production safety and efficiency today. Request a demo now to experience the difference.