Streamlining the Risk Assessment Process in oil and gas production is a critical aspect of ensuring safety and operational efficiency. With the advent of digital solutions like FAT FINGER, companies can now simplify and enhance their risk management strategies. FAT FINGER is a digital workflow procedure builder that empowers frontline teams to do their work properly.

It allows you to build checklists, workflows, and digital procedures that unlock operational excellence. With FAT FINGER, you can build digital workflow procedures to improve Risk Assessment and manage risks in your facility. Request a demo today to see how FAT FINGER can revolutionize your Risk Assessment Process.

The Importance of Risk Assessment in Oil and Gas Production

Risk assessment is a fundamental part of the oil and gas industry. It involves identifying potential hazards, evaluating their potential impact, and implementing measures to mitigate these risks. The process is crucial in preventing accidents, ensuring worker safety, and maintaining operational efficiency.

Challenges in Traditional Risk Assessment

Traditional risk assessment methods often involve manual processes, which can be time-consuming and prone to human error. These methods may also lack the flexibility to adapt to changing conditions or new information, making it difficult to effectively manage risks.

Streamlining Risk Assessment with FAT FINGER

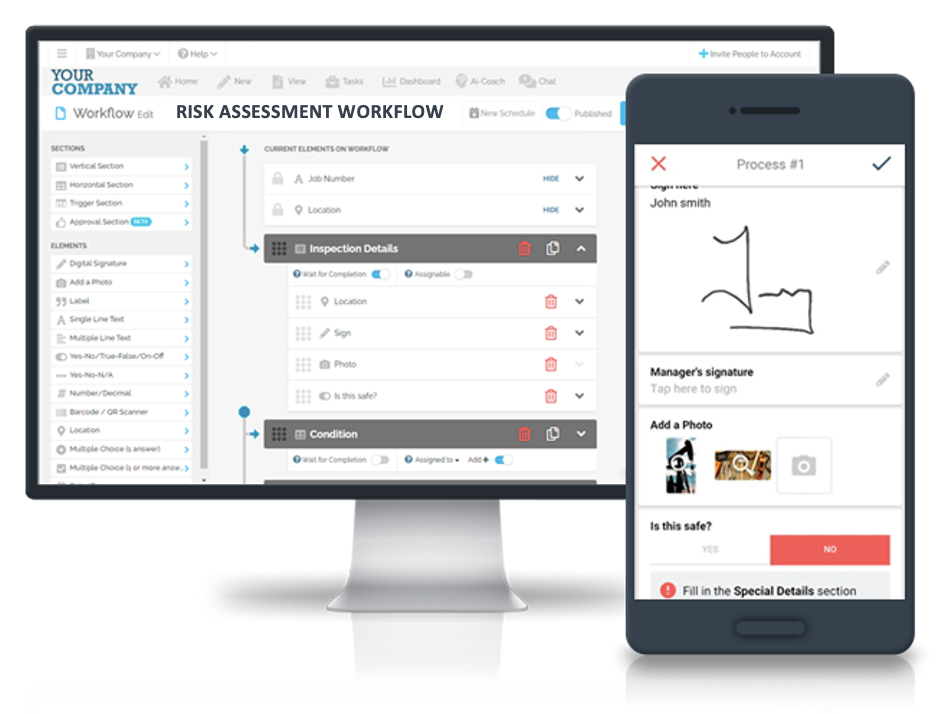

FAT FINGER offers a solution to these challenges by providing a platform for creating digital workflow procedures. These procedures can be used to streamline the Risk Assessment Process, making it more efficient and reliable. Here are some ways FAT FINGER can enhance your Risk Assessment Process:

- Drag & Drop Workflow Builder: This feature allows you to easily create and modify your risk assessment procedures.

- Mobile & Desktop Workflows: With FAT FINGER, you can access your workflows from any device, making it easier to conduct risk assessments on-site.

- Dashboards: FAT FINGER’s dashboards provide a visual representation of your risk data, making it easier to identify trends and areas of concern.

- Integrations: FAT FINGER can be integrated with other systems, allowing you to consolidate your risk data and streamline your processes.

- Augmented Reality, Connect IoT Devices, Artificial Intelligence Coaching: These advanced features can further enhance your Risk Assessment Process, providing additional insights and guidance.

Case Study: Improving Risk Assessment with FAT FINGER

One oil and gas company was able to significantly improve their Risk Assessment Process by implementing FAT FINGER. They used the platform to create a comprehensive risk assessment checklist, which was then distributed to all of their sites. This allowed them to standardize their Risk Assessment Process, ensuring that all potential hazards were consistently identified and addressed. As a result, they were able to reduce the number of accidents and improve their operational efficiency.

Conclusion

Streamlining the Risk Assessment Process in oil and gas production is crucial for ensuring safety and operational efficiency. With digital solutions like FAT FINGER, companies can simplify and enhance their risk management strategies. By leveraging the platform’s features, such as the drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, and advanced technologies, companies can create a more efficient and reliable Risk Assessment Process. Sign up for a free demo today to see how FAT FINGER can revolutionize your Risk Assessment Process.

Ready to streamline your risk assessment process in oil and gas production? Our innovative solutions can help you manage risks effectively and efficiently. Request a demo today and take the first step towards a safer, more productive operation.