In the manufacturing industry, Risk Assessment is a critical component of operational excellence. It is a proactive measure that helps to identify potential hazards, evaluate their impact, and implement appropriate control measures. With the advent of digital technology, risk assessment has become more efficient and effective. One such technology is FAT FINGER, a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. This article explores how to establish effective risk assessment policies in manufacturing using FAT FINGER. Request a demo today to see how FAT FINGER can revolutionize your risk assessment process.

Understanding Risk Assessment in Manufacturing

Risk assessment in manufacturing involves identifying potential hazards in the workplace, evaluating the likelihood of their occurrence, and implementing control measures to mitigate their impact. It is a continuous process that requires regular review and update to ensure its effectiveness.

The Role of FAT FINGER in Risk Assessment

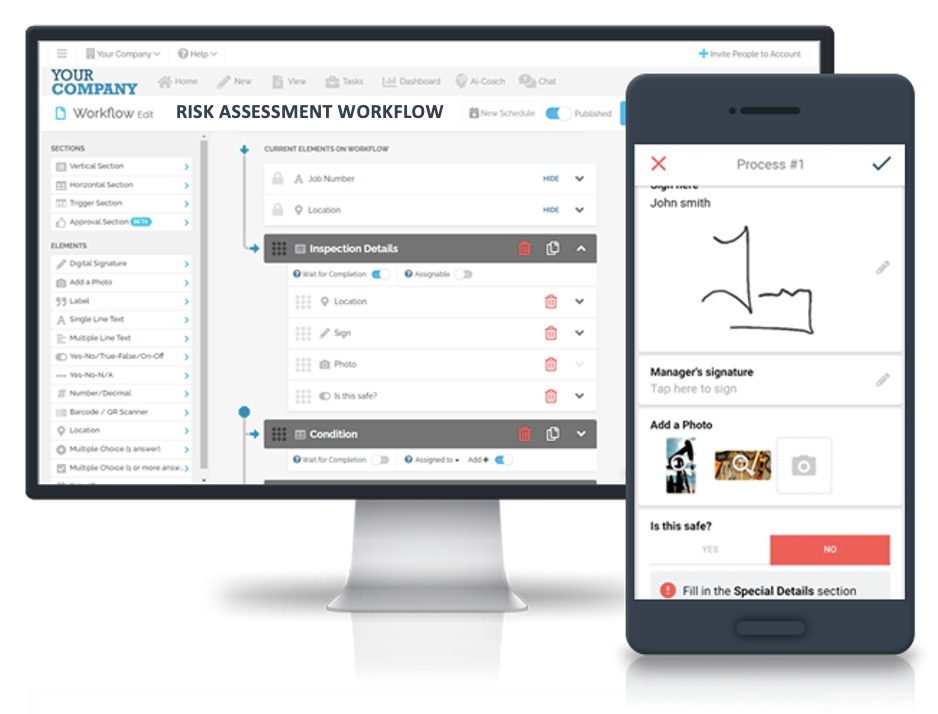

FAT FINGER plays a crucial role in risk assessment by providing a platform for creating digital workflow procedures. These procedures help to standardize the risk assessment process, making it easier for everyone in the organization to understand and follow. With FAT FINGER, you can create risk assessment checklists that help to safeguard your company from threats.

Key Features of FAT FINGER

- Drag & Drop Workflow Builder: This feature allows you to easily create and customize your risk assessment procedures.

- Mobile & Desktop Workflows: FAT FINGER workflows can be accessed on both mobile and desktop devices, making it convenient for your team to conduct risk assessments from anywhere.

- Dashboards: FAT FINGER provides dashboards that give you a visual representation of your risk assessment data, helping you to make informed decisions.

- Integrations: FAT FINGER can be integrated with other systems in your organization, ensuring a seamless flow of information.

- Augmented Reality, Connect IoT Devices, Artificial Intelligence Coaching: These advanced features enhance the effectiveness of your risk assessment process.

Creating a Risk Assessment Policy with FAT FINGER

Creating a Risk Assessment Policy with FAT FINGER involves a few simple steps. First, you need to identify the potential hazards in your workplace. This can be done by conducting a thorough inspection of your facility and consulting with your employees. Once the hazards have been identified, you can use the drag & drop workflow builder to create a risk assessment procedure.

This procedure should include steps for evaluating the likelihood of each hazard and implementing control measures. Finally, you can use the dashboards to monitor the effectiveness of your Risk Assessment Policy and make necessary adjustments.

Benefits of Using FAT FINGER for Risk Assessment

Using FAT FINGER for risk assessment offers several benefits. First, it standardizes the risk assessment process, making it easier for everyone in the organization to understand and follow. Second, it provides a visual representation of your risk assessment data, helping you to make informed decisions. Third, it allows for seamless integration with other systems in your organization, ensuring a smooth flow of information. Finally, it offers advanced features like augmented reality, IoT device connectivity, and artificial intelligence coaching, which enhance the effectiveness of your risk assessment process.

Conclusion

In conclusion, establishing effective risk assessment policies in manufacturing is crucial for operational excellence. With FAT FINGER, you can create digital workflow procedures that standardize the risk assessment process, making it easier for everyone in the organization to understand and follow. Furthermore, FAT FINGER provides a visual representation of your risk assessment data, helping you to make informed decisions. Request a demo today to see how FAT FINGER can revolutionize your risk assessment process.

Take the first step towards establishing effective risk assessment policies in your manufacturing business. Learn how to identify, analyze, and manage potential risks to ensure the safety and efficiency of your operations. Request a demo today to get started.