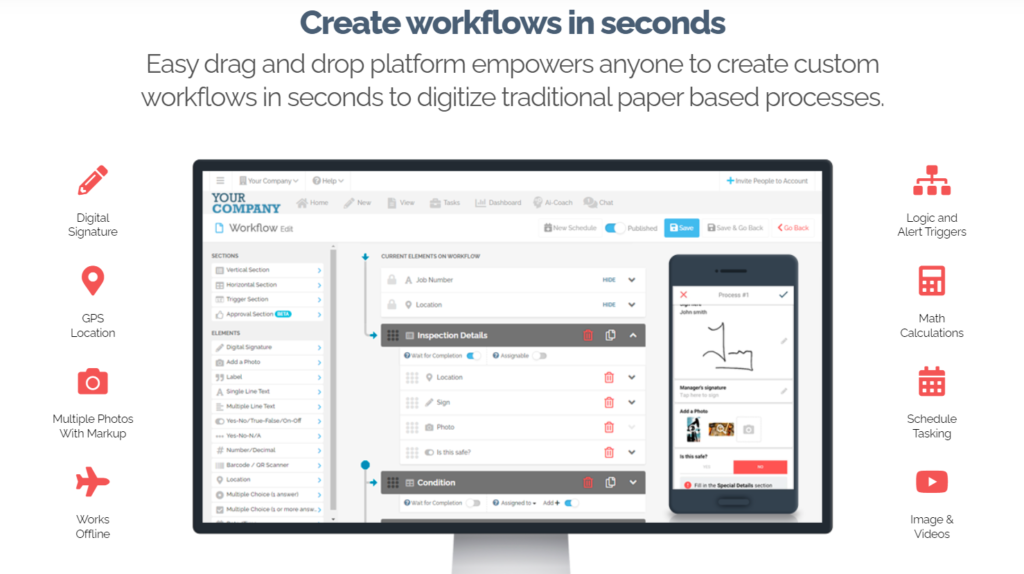

The oil and gas sector stands on the brink of a digital revolution. Connected Work Solutions, like FAT FINGER, are at the forefront, transforming how operations unfold in this high-stakes industry. FAT FINGER, a digital workflow procedure builder, empowers front-line teams to execute tasks flawlessly every time. It offers a suite of features including a Drag & Drop Workflow Builder, Mobile & Desktop Workflows, Dashboards, and more, ensuring operational excellence is within reach.

The Impact of Digital Transformation on Oil and Gas Operations

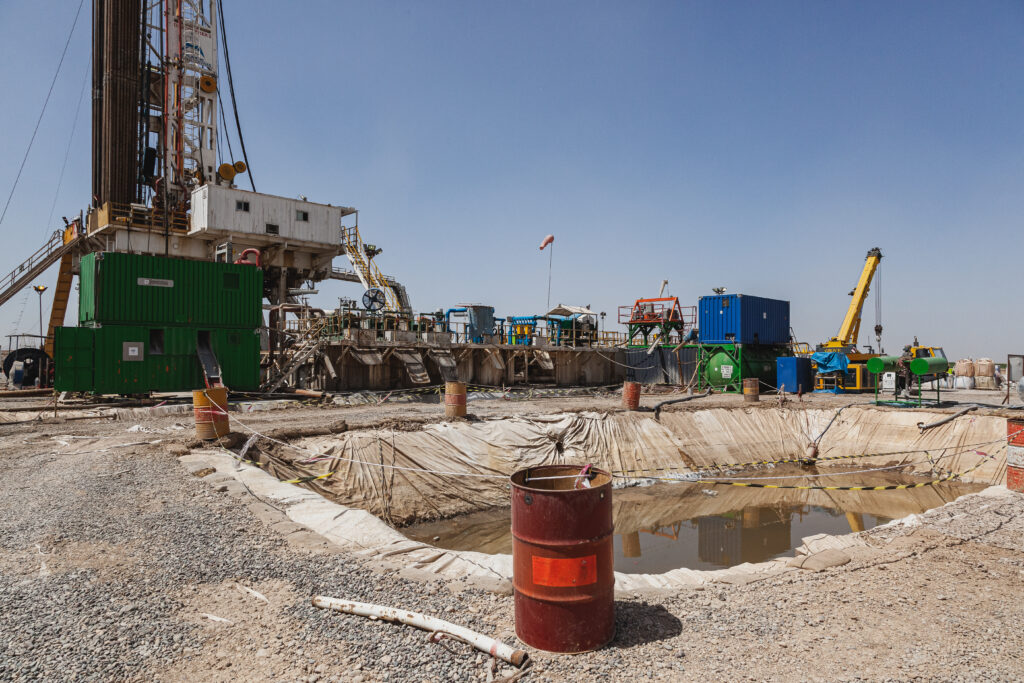

Digital transformation is reshaping the oil and gas landscape. Efficiency gains, cost reductions, and enhanced safety are just the tip of the iceberg. With real-time data at their fingertips, companies can make informed decisions swiftly, reducing downtime and boosting productivity. Connected Work Solutions are the driving force behind this seismic shift, offering unprecedented visibility and control over complex operations.

Key Features of Connected Work Solutions for Enhanced Efficiency

Connected Work Solutions like FAT FINGER bring a plethora of features to the table. The Drag & Drop Workflow Builder simplifies process creation, while Mobile & Desktop Workflows ensure accessibility across devices. Dashboards provide a bird’s-eye view of operations, and Integrations seamlessly connect with existing systems. Augmented Reality and IoT device connectivity further enhance the user experience, with Artificial Intelligence Coaching guiding teams through procedures.

Case Studies: Success Stories of Connected Work in Oil and Gas

Success stories abound in the oil and gas industry, where Connected Work Solutions have made a significant impact. Companies have reported marked improvements in compliance, reduced operational risks, and streamlined processes. These case studies serve as a testament to the transformative power of digital solutions like FAT FINGER in driving efficiency and safety in the field.

Overcoming Challenges and Risks in Implementing Connected Work Solutions

Adopting Connected Work Solutions is not without its challenges. Concerns over cybersecurity, data privacy, and the need for cultural change within organizations are common hurdles. However, with a strategic approach and robust security measures, these risks can be mitigated. Training and change management are also crucial in ensuring a smooth transition to these advanced digital tools.

The Future of Oil and Gas: Embracing Connected Work for Sustainable Operations

The future of oil and gas hinges on sustainable operations, and Connected Work Solutions are pivotal in this journey. As the industry moves towards greener practices, these digital tools will play a vital role in minimizing environmental impact and ensuring compliance with evolving regulations. Embracing Connected Work Solutions is not just a step towards efficiency; it’s a leap towards a more sustainable future.

In conclusion, the oil and gas industry is undergoing a digital metamorphosis, with Connected Work Solutions like FAT FINGER leading the charge. These innovative tools are not just enhancing efficiency and safety; they’re paving the way for a more sustainable future.

To experience the power of FAT FINGER and unlock operational excellence, sign up or request a demo today. Join the revolution and propel your operations to new heights.