As the world grapples with the effects of climate change, businesses are increasingly recognizing the need to reduce their environmental footprint. One effective way to achieve this is through efficient connected work practices. This article explores how digital workflow procedure builders like FAT FINGER can help businesses reduce their environmental impact while enhancing operational efficiency.

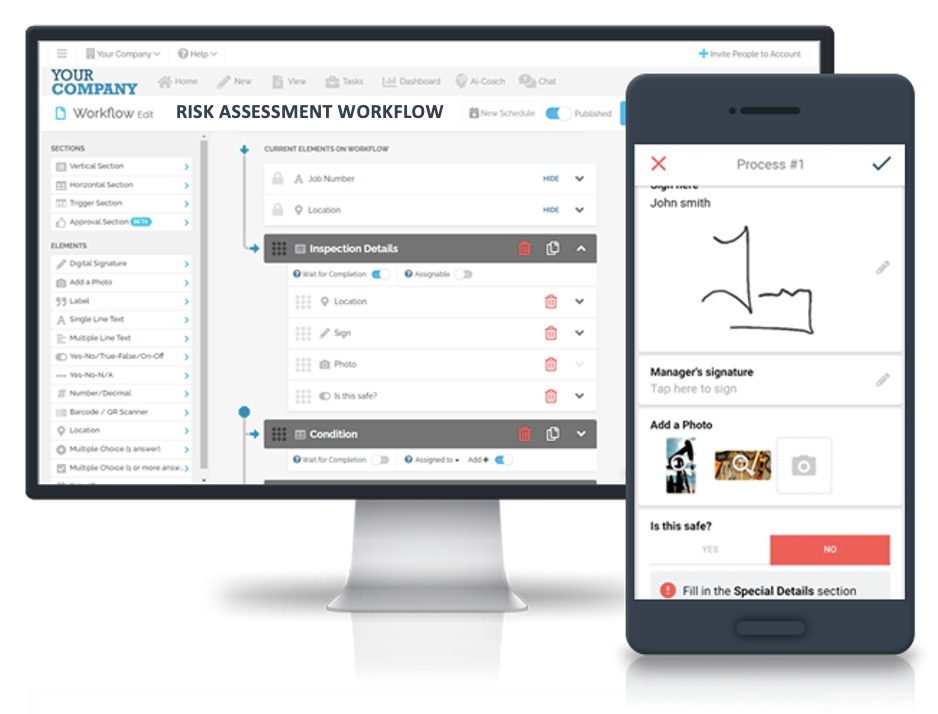

With FAT FINGER, front-line teams are empowered to do their work correctly every time. This is achieved through features like a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and artificial intelligence coaching. By improving facility inspection and production rounds, FAT FINGER can help businesses unlock operational excellence. Request a demo to see how FAT FINGER can transform your business operations.

The Environmental Impact of Traditional Work Practices

Traditional work practices often involve extensive use of paper, energy-intensive equipment, and unnecessary travel. These practices not only increase operational costs but also contribute significantly to environmental degradation. For instance, the pulp and paper industry is one of the largest consumers of water and energy and a major contributor to deforestation and greenhouse gas emissions.

How Connected Work Practices Reduce Environmental Impact

Connected work practices leverage digital technologies to streamline operations, reduce waste, and minimize environmental impact. Here’s how:

- Reduced paper use: Digital workflow builders like FAT FINGER eliminate the need for paper-based checklists and reports, significantly reducing paper waste.

- Energy efficiency: By optimizing workflows and reducing the need for energy-intensive equipment, businesses can significantly lower their energy consumption.

- Reduced travel: With remote access to workflows and reports, employees can work from anywhere, reducing the need for travel and associated carbon emissions.

Case Study: FAT FINGER and Environmental Impact Reduction

Many businesses have successfully used FAT FINGER to reduce their environmental impact. For instance, a manufacturing company was able to cut its paper use by 80% by switching to digital checklists and reports. This not only reduced the company’s environmental footprint but also improved data accuracy and operational efficiency.

Unlocking Operational Excellence with FAT FINGER

By improving facility inspection and production rounds, FAT FINGER can help businesses unlock operational excellence. A comprehensive inspection checklist can help keep your facility in good condition and avoid costly repairs or downtime. With FAT FINGER, you can build digital workflow procedures that are easy to follow, reducing errors and enhancing productivity.

Conclusion

Reducing environmental impact is not just good for the planet; it’s also good for business. Efficient connected work practices can help businesses lower their operational costs, improve productivity, and enhance their reputation as responsible corporate citizens. With digital workflow procedure builders like FAT FINGER, businesses can take a significant step towards a more sustainable future.

Ready to transform your business operations and reduce your environmental impact? Sign up to FAT FINGER today and start building your digital workflow procedures.

Join us in reducing environmental impact through efficient connected work practices. Make a difference today by adopting sustainable solutions for your business. Learn more and get started at fatfinger.io. Act now for a greener future!