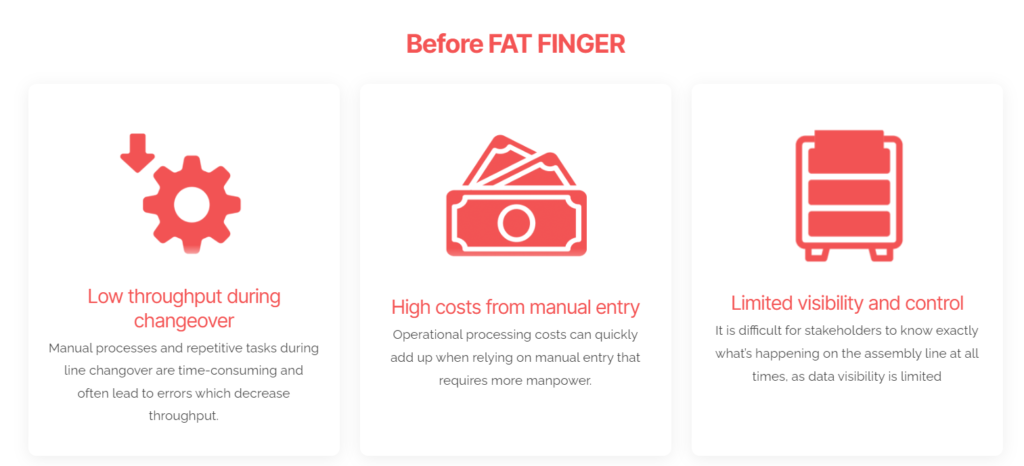

In the world of manufacturing, the efficiency and effectiveness of production lines are paramount. One of the key factors that can significantly impact these aspects is the variability of raw materials. This variability can pose challenges to Line Changeover strategies, potentially leading to increased downtime, reduced efficiency, and compromised product quality. However, with the right tools and strategies, these challenges can be effectively managed. One such tool is FAT FINGER, a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. With FAT FINGER, you can build digital line clearance procedures to facilitate seamless line changeovers, thereby unlocking operational excellence. Don’t just take our word for it, request a demo and see the difference FAT FINGER can make in your production line.

The Impact of Raw Material Variability

Raw material variability can have a significant impact on line changeover strategies. This variability can be due to a range of factors, including differences in material properties, supplier inconsistencies, and environmental conditions. These variations can lead to changes in the production process, requiring adjustments to equipment settings, process parameters, and quality control measures.

Challenges Posed by Raw Material Variability

Raw material variability can pose several challenges to line changeover strategies. These include:

- Increased downtime: The need to adjust equipment settings and process parameters to accommodate different raw materials can lead to increased downtime during line changeovers.

- Reduced efficiency: Variability in raw materials can lead to inconsistencies in the production process, reducing efficiency and increasing waste.

- Compromised product quality: If not properly managed, raw material variability can lead to variations in product quality, potentially leading to increased rework and returns.

Managing Raw Material Variability with FAT FINGER

Despite these challenges, raw material variability can be effectively managed with the right tools and strategies. One such tool is FAT FINGER. With its drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and artificial intelligence coaching, FAT FINGER empowers front-line teams to build digital line clearance procedures that facilitate seamless line changeovers.

By using FAT FINGER, production managers can streamline their production lines with confidence, knowing that everything is right at their fingertips. As one production manager put it, “FAT FINGER is a game changer for our production line clearance process.”

Conclusion

In conclusion, while raw material variability can pose challenges to line changeover strategies, these challenges can be effectively managed with the right tools and strategies. By using a tool like FAT FINGER, production managers can streamline their production lines, reduce downtime, improve efficiency, and ensure product quality. So why wait? Sign up for FAT FINGER today and unlock the full potential of your production line.

Discover how raw material variability impacts line changeover strategies. Learn how to optimize your production line and reduce downtime. Visit here for more information.