Key Takeaways:

- Ensuring Compliance: Quality assurance (QA) in inspections ensures compliance with industry standards and regulations, maintaining operational integrity.

- Enhancing Reliability: Regular inspections and QA processes enhance the reliability and safety of equipment and infrastructure.

- Utilizing Digital Tools: Implementing digital tools like FAT FINGER streamlines QA processes, ensuring thorough and efficient inspections.

Quality Assurance & Control in Oil & Gas Asset Inspections

Quality assurance and quality control are critical components of any successful business operation. They ensure that products and services meet the required standards and expectations. In the world of inspections, these two elements are even more crucial. They guarantee the reliability and accuracy of inspection results, which in turn, influence business decisions and strategies.

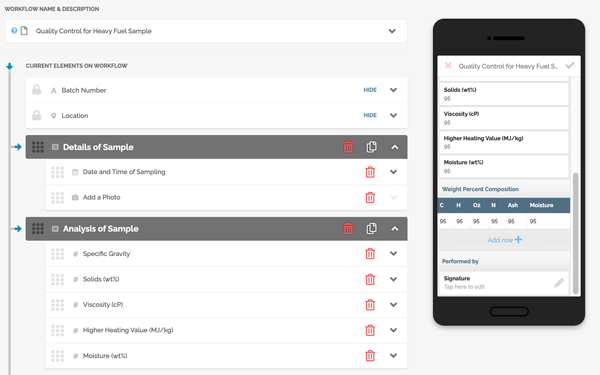

One tool that has proven to be a game-changer in this regard is FAT FINGER. With its digital workflows, FAT FINGER has revolutionized the way inspections are conducted, ensuring quality and reliability every step of the way. Request a demo today to see how FAT FINGER can transform your inspection processes.

The Importance of Quality Assurance and Quality Control in Inspections

Quality assurance (QA) and quality control (QC) are two sides of the same coin. While QA focuses on preventing defects through planned and systematic activities, QC identifies and corrects defects in the finished product. In inspections, these two processes work hand in hand to ensure the accuracy and reliability of results.

- QA in Inspections: QA in inspections involves developing a systematic approach to ensure that inspections are conducted correctly. This includes creating inspection plans, training inspectors, and implementing a system for continuous improvement.

- QC in Inspections: QC in inspections, on the other hand, involves checking the inspection results against the established standards. This ensures that any deviations are identified and corrected promptly.

Without effective QA and QC, inspection results may be unreliable, leading to incorrect decisions and potential losses. This is where FAT FINGER comes in.

How FAT FINGER Enhances QA and QC in Inspections

FAT FINGER’s digital workflows offer a robust solution for enhancing QA and QC in inspections. Here’s how:

- Standardization: FAT FINGER allows you to standardize your inspection processes, ensuring consistency and reducing the risk of errors.

- Real-time Data: With FAT FINGER, you can collect and analyze data in real-time, enabling immediate corrective actions and continuous improvement.

- Training and Support: FAT FINGER provides comprehensive training and support, ensuring that your inspectors are well-equipped to conduct inspections effectively.

- Reporting and Analytics: FAT FINGER’s advanced reporting and analytics capabilities allow you to monitor your inspection processes closely, identify trends, and make informed decisions.

By integrating FAT FINGER into your inspection processes, you can significantly enhance your QA and QC, ensuring reliable and accurate results.

Case Study: Improving Inspection Quality with FAT FINGER

Let’s take a look at a real-life example of how FAT FINGER has helped improve inspection quality. A leading manufacturing company was struggling with inconsistent inspection results due to manual processes and lack of standardization.

After implementing FAT FINGER, they were able to standardize their inspection processes, reduce errors, and improve the reliability of their inspection results. The company also reported a significant improvement in their QA and QC, leading to better decision-making and increased customer satisfaction.

Conclusion

Quality assurance and quality control are essential for ensuring the reliability and accuracy of inspection results. By integrating a robust tool like FAT FINGER into your inspection processes, you can enhance your QA and QC, leading to better decision-making and improved business outcomes.

Don’t let inconsistent and unreliable inspection results hold your business back. Create a mobile asset inspection workflow for free on FAT FINGER today or request a demo.

FAQs for Quality Assurance in Oil and Gas Inspections

Q: What is quality assurance (QA) in oil and gas inspections?

Quality assurance in oil and gas inspections involves systematic procedures to ensure that all equipment, processes, and operations comply with industry standards and regulations. QA processes aim to maintain high-quality and safe operations.

Q: Why is QA important in the oil and gas industry?

QA is essential for ensuring the safety, reliability, and efficiency of operations. It helps identify and rectify potential issues before they lead to failures, ensuring compliance with safety standards and regulations.

Q: What are the key components of a QA program in oil and gas inspections?

Key components include regular inspections, documentation, risk assessments, corrective actions, and continuous monitoring. These elements work together to ensure that all operations and equipment meet safety and quality standards.

Q: How do regular inspections contribute to QA?

Regular inspections help identify potential problems and ensure that equipment and processes are in good working condition. They are critical for maintaining operational integrity and preventing accidents.

Q: What role do digital tools play in QA for oil and gas inspections?

Digital tools streamline QA processes by providing real-time data, facilitating accurate record-keeping, and ensuring thorough inspections. Tools like FAT FINGER enhance efficiency and compliance in QA procedures.

Q: How can companies ensure effective QA in their inspections?

Effective QA involves implementing systematic inspection processes, utilizing digital tools, training personnel, and conducting regular audits. Ensuring that all procedures are followed consistently is key to maintaining high-quality standards.

Q: What are the benefits of using FAT FINGER for QA in oil and gas inspections?

FAT FINGER provides digital checklists, real-time reporting, and compliance tracking, ensuring thorough and efficient inspections. Its user-friendly interface and comprehensive features enhance overall QA processes.

Q: How does QA improve the reliability of equipment and infrastructure?

QA processes ensure that all equipment and infrastructure are maintained to high standards, reducing the risk of failures. Regular inspections and maintenance activities help identify and address issues before they escalate.

Q: Why is documentation important in QA processes?

Documentation provides a record of inspections, maintenance activities, and corrective actions. It ensures traceability, accountability, and compliance with industry standards, making it easier to track and manage QA activities.

Q: How can companies promote a culture of quality assurance?

Promoting a culture of QA involves training employees on QA processes, encouraging proactive identification of issues, and emphasizing the importance of compliance and continuous improvement. Leadership commitment to QA is also crucial for fostering a quality-focused environment.