Quality assurance is a critical aspect of automotive manufacturing. It ensures that the vehicles produced meet the highest standards of safety, performance, and reliability. However, traditional methods of quality assurance can be time-consuming, error-prone, and inefficient. This is where FAT FINGER comes in. FAT FINGER is a digital workflow procedure builder that allows you to create checklists, workflows, and digital procedures that unlock operational excellence. In this article, we will delve into how FAT FINGER can revolutionize quality assurance in automotive manufacturing.

Ready to transform your quality assurance process? Request a demo today.

Understanding FAT FINGER

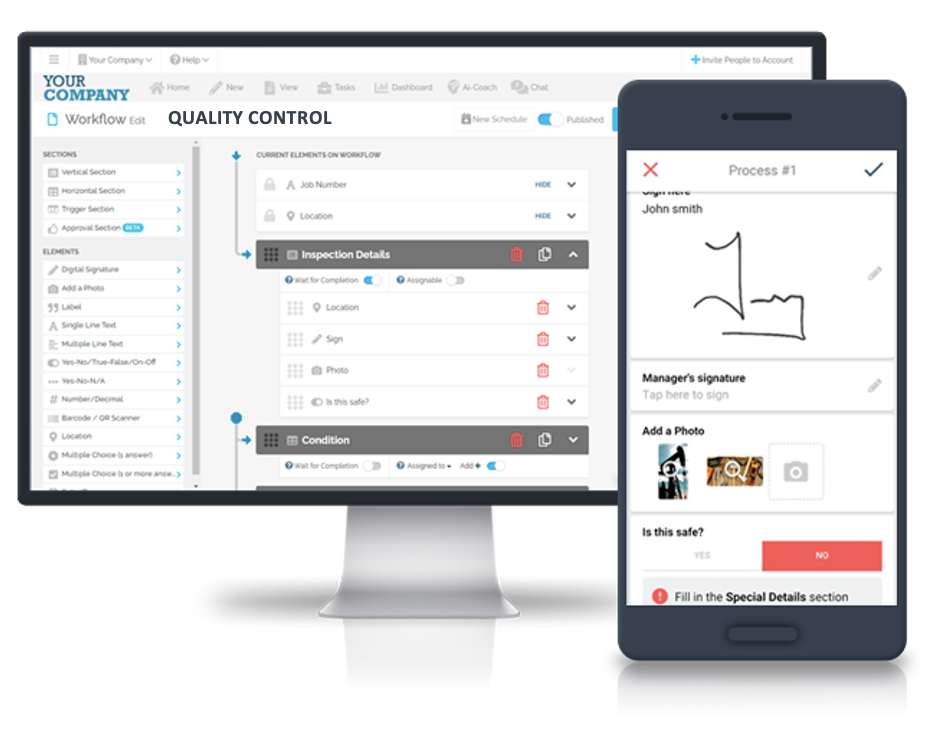

FAT FINGER is a software solution designed to streamline and automate workflow procedures. It provides a platform for creating digital checklists and workflows that can be used across various industries, including automotive manufacturing. With FAT FINGER, you can build custom apps to manage your quality assurance processes, ensuring that every vehicle produced meets the highest standards.

Key Features of FAT FINGER

- Easy-to-use interface: FAT FINGER’s intuitive interface allows you to create and manage workflows with ease.

- Customizable workflows: You can build custom workflows to suit your specific quality assurance needs.

- Real-time data: FAT FINGER provides real-time data, allowing you to monitor your processes and make informed decisions.

- Integration capabilities: FAT FINGER can be integrated with other systems, providing a seamless workflow experience.

How FAT FINGER Enhances Quality Assurance in Automotive Manufacturing

Quality assurance in automotive manufacturing involves a series of checks and balances. These checks ensure that every part of the vehicle, from the engine to the upholstery, is up to standard. Here’s how FAT FINGER can enhance this process:

Streamlining Workflow

With FAT FINGER, you can create digital workflows that streamline your quality assurance process. These workflows can guide your team through each step of the process, ensuring that nothing is overlooked. This not only increases efficiency but also reduces the risk of errors.

Real-Time Monitoring

FAT FINGER’s real-time data capabilities allow you to monitor your quality assurance process in real-time. This means you can identify and address issues as they arise, preventing small problems from becoming major setbacks.

Integration with Other Systems

FAT FINGER can be integrated with other systems, such as your inventory management or customer relationship management system. This allows for a seamless workflow, where data from different systems can be accessed and used in your quality assurance process.

Case Study: Improving Quality Assurance with FAT FINGER

Let’s take a look at a real-world example of how FAT FINGER can improve quality assurance in automotive manufacturing. Our client, a leading automotive manufacturer, was struggling with their quality assurance process. It was time-consuming, error-prone, and inefficient. They turned to FAT FINGER for a solution.

With FAT FINGER, they were able to create a digital workflow that streamlined their quality assurance process. They could monitor their process in real-time, allowing them to identify and address issues as they arose. The result? A more efficient, accurate, and reliable quality assurance process.

Conclusion

Quality assurance is crucial in automotive manufacturing. With FAT FINGER, you can streamline your quality assurance process, ensuring that every vehicle you produce meets the highest standards. From creating custom workflows to providing real-time data, FAT FINGER offers a comprehensive solution for quality assurance in automotive manufacturing.

Ready to revolutionize your quality assurance process? Build a digital workflow for free on FAT FINGER or schedule a demo today.