Heavy machinery manufacturing is a complex industry that requires precise coordination of various processes, including procurement and supply chain management. These processes can be challenging to manage due to their complexity and the high stakes involved. However, with the advent of digital workflow procedure builders like FAT FINGER, these challenges can be significantly mitigated. FAT FINGER is a revolutionary tool that allows you to build checklists, workflows, and digital procedures that unlock operational excellence. This article will delve into how FAT FINGER can streamline procurement and supply chain processes in heavy machinery manufacturing.

Introducing FAT FINGER

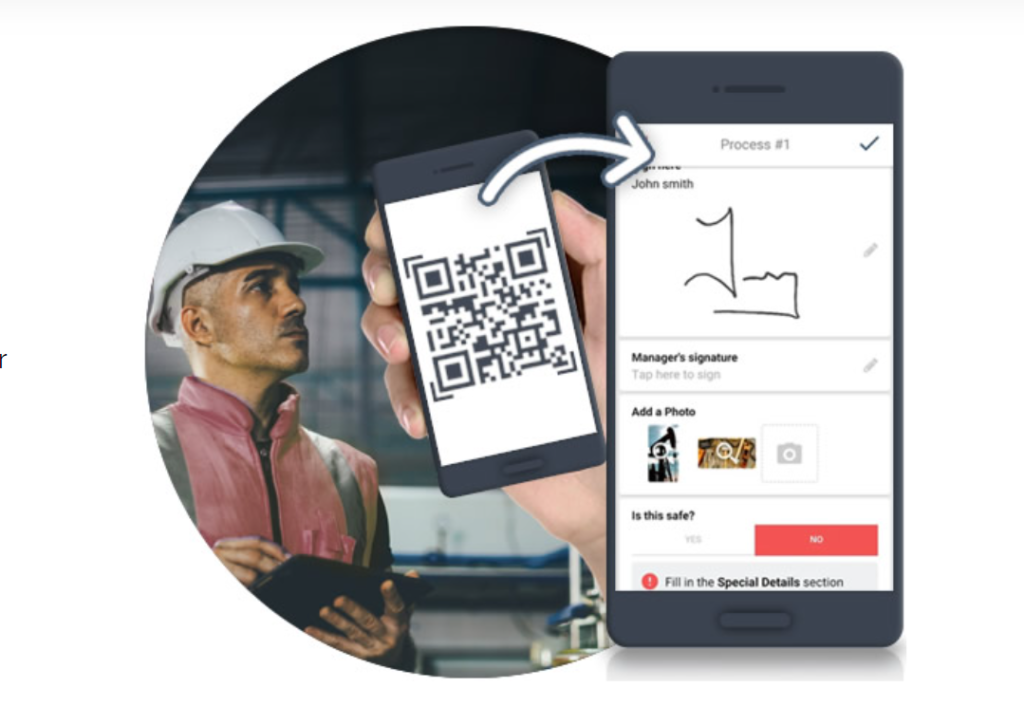

FAT FINGER is a digital workflow procedure builder that enables businesses to create checklists, workflows, and digital procedures. Its features include a drag and drop workflow builder, augmented reality, AI Coach, IoT device connectivity, integrations, mobile and desktop workflows, and dashboards. These features provide a comprehensive solution for streamlining procurement and supply chain processes in heavy machinery manufacturing.

Request a Demo

Experience the power of FAT FINGER firsthand by requesting a demo. Witness how this innovative tool can revolutionize your procurement and supply chain processes.

Streamlining Procurement with FAT FINGER

Procurement in heavy machinery manufacturing involves sourcing and purchasing raw materials, parts, and services. This process can be complex and time-consuming, but FAT FINGER can streamline it in several ways:

- Workflow Builder: FAT FINGER’s drag and drop workflow builder allows you to create custom procurement workflows that suit your specific needs. This feature ensures that all procurement steps are followed accurately and consistently, reducing errors and inefficiencies.

- AI Coach: FAT FINGER’s AI Coach can provide real-time guidance and support during the procurement process, helping to prevent mistakes and improve decision-making.

- Integrations: FAT FINGER can be integrated with other systems used in procurement, such as ERP and CRM systems. This integration allows for seamless data sharing and coordination, improving efficiency and accuracy.

Optimizing Supply Chain Processes with FAT FINGER

Supply chain processes in heavy machinery manufacturing involve the movement and storage of raw materials, work-in-process inventory, and finished goods. FAT FINGER can optimize these processes in the following ways:

- Connect to IoT devices: FAT FINGER can connect to IoT devices used in supply chain management, such as RFID tags and GPS trackers. This connectivity allows for real-time tracking and monitoring of goods, improving visibility and control.

- Mobile and Desktop Workflows: FAT FINGER’s mobile and desktop workflows enable supply chain processes to be managed from anywhere, at any time. This flexibility improves responsiveness and efficiency.

- Dashboards: FAT FINGER’s dashboards provide a visual representation of supply chain data, making it easier to monitor and manage. This feature can help identify bottlenecks and opportunities for improvement.

Why Choose FAT FINGER?

Choosing FAT FINGER for streamlining procurement and supply chain processes in heavy machinery manufacturing offers several benefits. It not only improves efficiency and accuracy but also reduces costs and risks. Moreover, it provides a competitive edge by enabling faster and smarter decision-making.

Build a Digital Workflow for Free

Start streamlining your procurement and supply chain processes today by building a digital workflow for free on FAT FINGER. Alternatively, you can schedule a demo to see how FAT FINGER can benefit your heavy machinery manufacturing business.

Conclusion

In conclusion, FAT FINGER is a powerful tool that can streamline procurement and supply chain processes in heavy machinery manufacturing. Its features such as the drag and drop workflow builder, AI Coach, IoT device connectivity, integrations, mobile and desktop workflows, and dashboards provide a comprehensive solution for these complex processes. By choosing FAT FINGER, heavy machinery manufacturers can improve efficiency, reduce costs, and gain a competitive edge.