Preventive maintenance is a crucial aspect of any successful business operation. It involves regular, scheduled maintenance of company equipment and machinery to prevent costly and disruptive breakdowns. With the advent of digital workflow procedure builders like FAT FINGER, preventive maintenance has become more efficient and effective.

FAT FINGER empowers front-line teams to do their work correctly every time, by letting you build checklists, workflows, and digital procedures that unlock operational excellence. This article will delve into the importance of designing an effective Preventive Maintenance Program and how FAT FINGER can help you achieve this. Request a demo to see how FAT FINGER can revolutionize your Preventive Maintenance Program.

Understanding Preventive Maintenance

Preventive maintenance is a proactive approach that involves regular inspections, servicing, and repairs to prevent potential equipment failures or breakdowns. It’s a crucial part of any business operation, as it helps to extend the lifespan of machinery, improve safety, and reduce downtime. With the help of FAT FINGER, you can build predictive maintenance digital workflows to ensure problems are gone even before they start.

The Importance of Preventive Maintenance

Preventive maintenance offers a myriad of benefits for businesses. Here are a few key advantages:

- It extends the lifespan of your equipment, reducing the need for costly replacements.

- It improves the efficiency of your equipment, leading to increased productivity.

- It reduces downtime caused by equipment failures, which can disrupt operations and lead to lost revenue.

- It helps to ensure that safety standards are adhered to throughout the lifecycle of all machines.

Designing an Effective Preventive Maintenance Program with FAT FINGER

Designing an effective Preventive Maintenance Program involves several key steps. Here’s how FAT FINGER can assist in each stage:

1. Inventory of Assets

Firstly, you need to take an inventory of all your assets. FAT FINGER’s easy-to-use interface allows you to quickly and accurately log all your equipment, ensuring nothing is overlooked.

2. Determine Maintenance Tasks

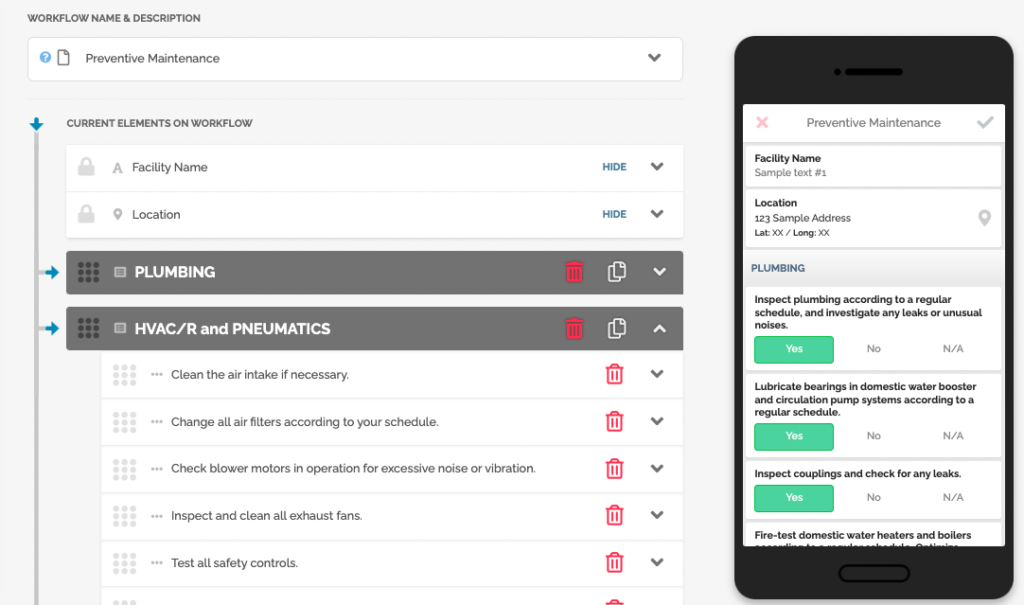

Next, determine what maintenance tasks need to be performed on each piece of equipment. FAT FINGER’s drag and drop workflow builder makes it easy to create detailed, step-by-step maintenance procedures.

3. Schedule Maintenance

With FAT FINGER, you can easily schedule maintenance tasks to ensure they’re carried out at the optimal time. This helps to prevent breakdowns and extend the lifespan of your equipment.

4. Monitor and Adjust

Finally, monitor the effectiveness of your Preventive Maintenance Program and make adjustments as necessary. FAT FINGER’s dashboards provide real-time insights into your maintenance operations, allowing you to quickly identify and address any issues.

Case Study: Predictive Maintenance with FAT FINGER

Predictive maintenance is an engineer’s best friend and a powerful tool for optimizing platforms in a manufacturing facility. Instead of having scheduled maintenance done on a predetermined timeframe, predictive maintenance uses data and technology to specify when maintenance needs to be completed to prevent costly breakdowns accurately. It works by collecting data from a facility’s various components and then using it to determine when parts need maintenance, as well as use algorithms or Artificial Intelligence (AI), if necessary. Predictive maintenance can help save time and money, improve efficiency in the facility, and help ensure that safety standards are adhered to throughout the lifecycle of all machines.

Conclusion

Preventive maintenance is a crucial aspect of any successful business operation. With the help of FAT FINGER, designing an effective Preventive Maintenance Program has never been easier. From taking an inventory of assets to scheduling maintenance tasks, FAT FINGER provides all the tools you need to keep your equipment running smoothly and efficiently. Create a predictive maintenance workflow for free on FAT FINGER or schedule a demo to see how FAT FINGER can revolutionize your Preventive Maintenance Program.

Ready to ensure the longevity of your equipment and reduce downtime? Start designing an effective preventive maintenance program for long-term benefits today. Schedule a Demo now and let us guide you through the process.