Manufacturing is a complex process that requires meticulous planning and scheduling. One of the key factors that can significantly impact productivity in manufacturing is the efficiency of scheduling. This is where FAT FINGER, a digital workflow procedure builder, comes into play. It empowers front-line teams to do their work correctly every time, unlocking operational excellence.

Understanding the Importance of Scheduling in Manufacturing

Scheduling in manufacturing is a critical aspect that determines the efficiency of the production process. It involves planning and coordinating the sequence of tasks, ensuring optimal utilization of resources, and minimizing downtime. Effective scheduling can lead to improved productivity, reduced costs, and enhanced customer satisfaction.

Challenges in Manufacturing Scheduling

Despite its importance, many manufacturers face challenges in scheduling. These include unpredictable demand, equipment breakdowns, and labor shortages. These challenges can lead to production delays, increased costs, and reduced customer satisfaction.

How FAT FINGER Can Help

FAT FINGER can help overcome these challenges by providing a platform for creating digital workflows and checklists. These can be used across various safety, maintenance, and operations areas, including:

- Safety: Take 5 Safety, Near miss reporting, JSA / JHA, Risk Assessment, Incident reporting, Journey report

- Operations: Material Inspection, Quality Control, Shift Handover, Facility inspection / Production rounds, Line Changeover, Field ticket

- Maintenance: Work Order Checklist, Truck inspection checks, Mobile Asset Inspection, Shutdown / Turnaround form, Preventive maintenance inspection, Predictive Maintenance

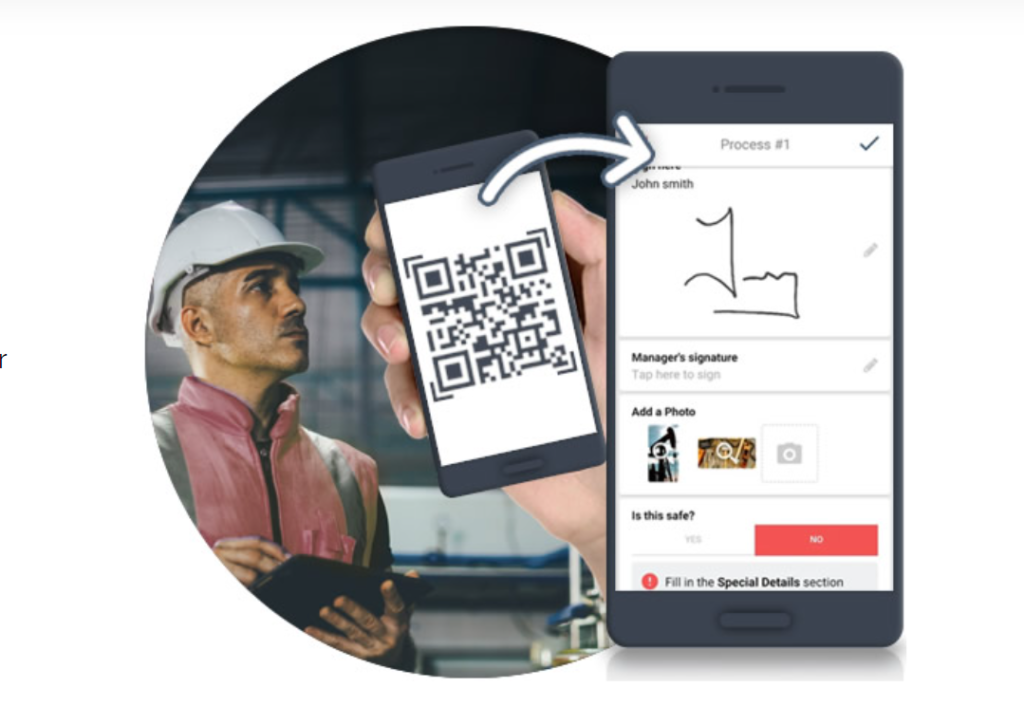

With its drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and artificial intelligence coaching, FAT FINGER can significantly enhance the efficiency of scheduling in manufacturing.

Case Study: Improving Productivity with FAT FINGER

Consider the case of a leading manufacturing company that was struggling with scheduling inefficiencies. After implementing FAT FINGER, they were able to streamline their scheduling process, reduce downtime, and improve productivity. The company reported a 20% increase in productivity and a significant reduction in costs.

Key Takeaways

Optimizing scheduling in manufacturing is crucial for improving productivity. Despite the challenges, solutions like FAT FINGER can help manufacturers streamline their scheduling process, reduce downtime, and enhance productivity. With its comprehensive features and capabilities, FAT FINGER is a valuable tool for any manufacturer looking to optimize their scheduling and improve productivity.

Get Started with FAT FINGER

Are you ready to take your Manufacturing scheduling to the next level? Sign up for FAT FINGER or request a demo today to see how it can help you unlock operational excellence.

Boost your manufacturing productivity today by optimizing your scheduling. Visit FatFinger to learn how you can streamline your processes for improved efficiency.