Operational efficiency is a critical factor in the oil sector. It determines the success of oil companies and impacts the global economy. One of the most effective ways to enhance operational efficiency is through Quality Control. This article explores how quality control can improve operational efficiency in the oil sector, with a particular focus on the role of FAT FINGER, a digital workflow procedure builder that empowers front-line teams to do their work correctly every time.

Why Quality Control Matters in the Oil Sector

Quality control is essential in the oil sector for several reasons. It ensures the safety and reliability of operations, reduces waste, and increases productivity. By identifying and correcting defects early in the production process, companies can avoid costly repairs and downtime. Quality control also helps to maintain the reputation of oil companies, as high-quality products and services are more likely to attract and retain customers.

How FAT FINGER Enhances Quality Control

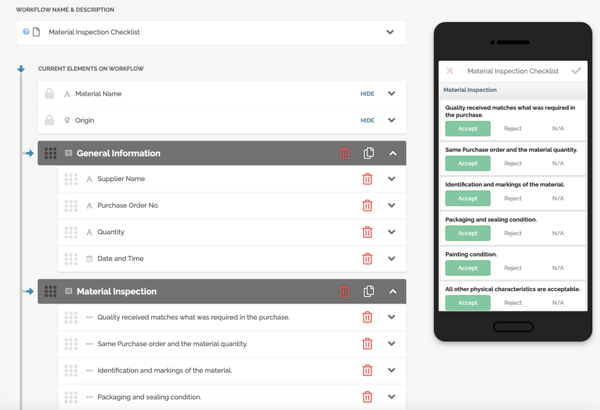

FAT FINGER is a game-changer in the realm of quality control. It allows companies to build digital workflow procedures that unlock operational excellence. With features like Drag & Drop Workflow Builder, Mobile & Desktop Workflows, Dashboards, Integrations, Augmented Reality, Connect IoT Devices, and Artificial Intelligence Coaching, FAT FINGER provides a comprehensive solution for enhancing quality control in the oil sector.

Powerful Checklists for Operational Efficiency

One of the key features of FAT FINGER is its ability to build powerful checklists that boost operational efficiency. Here are some examples:

- Material Inspection: With FAT FINGER, companies can ensure the highest quality standards of their products with a digital material inspection. Defects can be identified early in the production process, reducing reliance on manual labor and preventing costly mistakes.

- Quality Control: FAT FINGER enables companies to ensure that what their customers get presents the best of their brand. With customized automated workflow, companies can reach maximum production potential and transition from paperwork processes to digital ones in minutes.

- Shift Handover: FAT FINGER transforms the way frontline shift management works, modernizing shift transition and saving time and money.

- Facility Inspection: With FAT FINGER, companies can ensure their facility keeps running without a hitch. The platform allows for streamlined checklists, SOPs, and inspections, and generates professional reports in an instant.

- Line Changeover: FAT FINGER helps companies get the most out of their production by seamlessly transitioning between processes. The platform cuts down tedious tasks like manual reporting and quality monitoring, and syncs up teams with automated recurring scheduling.

- Electronic Field Ticket: FAT FINGER ushers in a new era of engineering with electronic tickets. The platform cuts out tedious tasks and boosts productivity with automated field reporting, workforce scheduling, and invoicing.

Conclusion

Quality control is a critical factor in enhancing operational efficiency in the oil sector. With the help of FAT FINGER, companies can build digital workflow procedures that unlock operational excellence, reduce waste, increase productivity, and maintain their reputation. By leveraging the power of FAT FINGER, oil companies can take their operations to the next level.

Ready to enhance your operational efficiency through quality control? Request a demo of FAT FINGER today and see how it can transform your operations. And if you’re ready to build a safety checklist with FAT FINGER, get started now and take the first step towards operational excellence.

Discover how to enhance operational efficiency through quality control in the oil sector. Learn more about our innovative solutions and how they can transform your business operations. Don’t wait, Request A Demo today and take the first step towards operational excellence.