As the world continues to shift towards renewable energy, offshore wind farms have emerged as a promising solution. However, these wind farms face a myriad of operational challenges. This is where FAT FINGER comes in. FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. With FAT FINGER, you can build checklists, workflows, and digital procedures that unlock operational excellence. Request a demo today to see how FAT FINGER can revolutionize your offshore wind farm operations.

Operational Challenges of Offshore Wind Farms

Offshore wind farms face several operational challenges, including:

- Harsh weather conditions that can damage equipment and disrupt operations

- High maintenance costs due to the remote and difficult-to-access locations

- Logistical challenges in transporting materials and personnel to and from the site

- Regulatory and environmental compliance issues

How FAT FINGER Can Help

FAT FINGER can help address these challenges by providing a platform for creating digital workflow procedures. These procedures can improve safety, increase efficiency, and ensure compliance with regulations. Here are some powerful checklists you can build with FAT FINGER to boost operational efficiency:

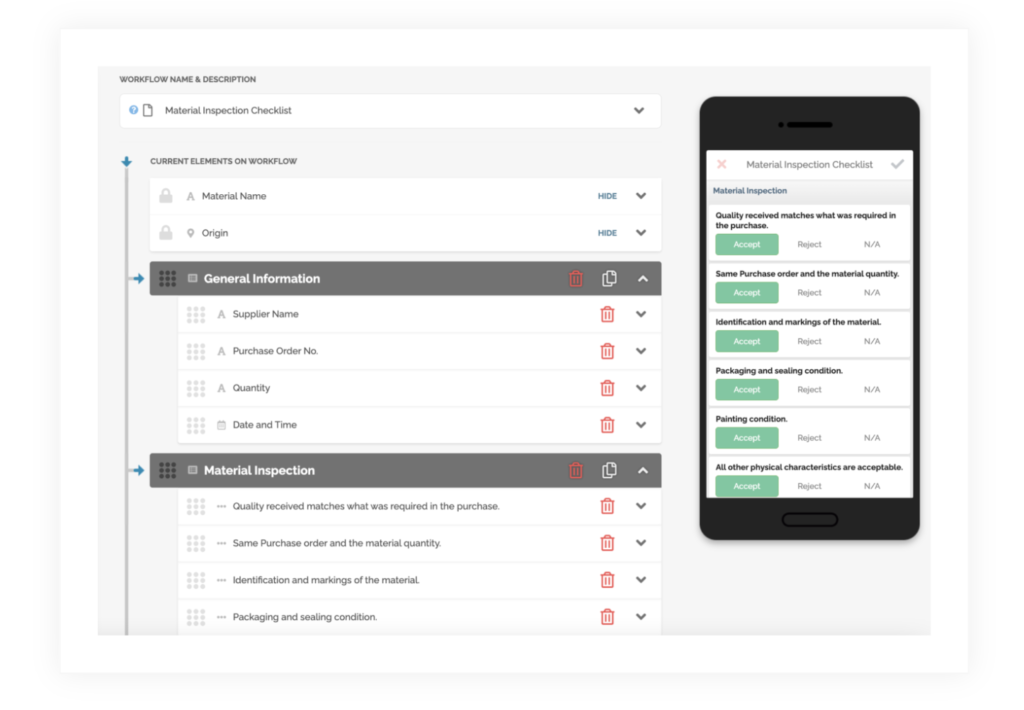

Material Inspection

Ensure the highest quality standards of your products with a digital material inspection. With our revolutionary workflow, materials can be inspected quickly and accurately with less reliance on manual labor. Defects can be identified early in the production process before they become too costly.

Quality Control

Reach maximum production potential with customized automated workflow. Smart workflow enables a seamless transition from paperwork processes to digital ones in minutes. Generate custom reports that will keep everyone on track for operational excellence.

Shift Handover

Modernize your shift transition and watch the savings skyrocket. Automate tedious, monotonous tasks quickly – and keep your entire team in the loop. Get back to the important stuff with clear communication that maximizes output while saving your time.

Facility Inspection

Elevate your team’s facility inspection to new heights. Streamline your checklists, SOPs and inspections with our intuitive workflow solution. Generate professional reports in an instant. Revolutionize facility inspections quickly without compromising excellence.

Line Changeover

Take your line changeover into a cost effective future with digitalization. Cutting down tedious tasks like manual reporting and quality monitoring is now easier than ever. Get your team synced up in no time with automated recurring scheduling so everyone’s on the same page without any lost work hours – more productivity, less stress.

Electronic Field Ticket

Upgrade your ticketing system and save big. Cut out tedious tasks and boost your team’s productivity with automated field reporting, workforce scheduling, and invoicing. Set up recurring projects in no time – giving everyone the same page from start to finish so you can focus on getting results!

Conclusion

Offshore wind farms face numerous operational challenges, but with the right tools and strategies, these can be effectively managed. FAT FINGER provides a powerful solution for creating digital workflow procedures that can improve safety, increase efficiency, and ensure compliance with regulations. By leveraging the power of FAT FINGER, offshore wind farms can overcome their operational challenges and achieve operational excellence. Build a safety checklist with FAT FINGER today and revolutionize your offshore wind farm operations.

Facing operational challenges with your offshore wind farms? Discover effective solutions today! Visit FatFinger.io to learn how you can overcome these challenges and optimize your operations. Don’t wait, explore now!