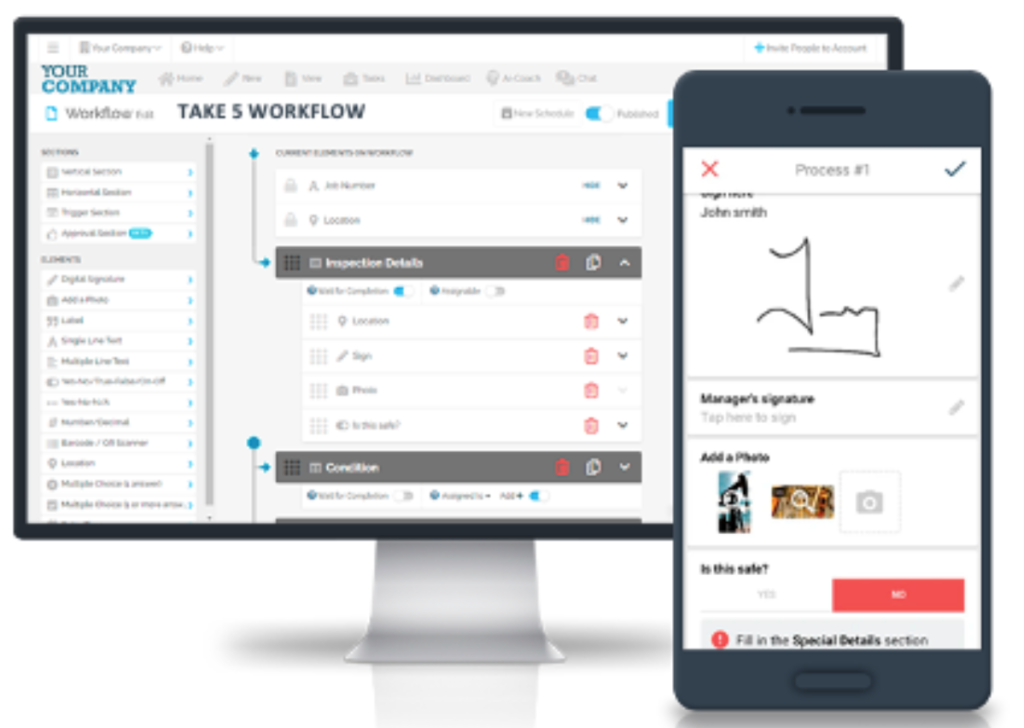

Heavy industries are the backbone of our economy. They are also environments where risk is a constant companion. In these sectors, health and safety are not just policies; they are vital practices that protect lives and the bottom line. Recognizing the importance of these practices, FAT FINGER offers a digital workflow procedure builder that empowers front-line teams to execute their tasks flawlessly every time. With features like a Drag & Drop Workflow Builder and Mobile & Desktop Workflows, FAT FINGER ensures that safety protocols are not just written but actively followed.

Understanding the Key Health and Safety Regulations

Health and safety regulations in heavy industries are complex. They are designed to mitigate occupational hazards and ensure employee welfare. The regulatory framework includes:

– OSHA standards

– EPA guidelines for hazardous materials

– Local and international safety codes

These regulations cover everything from the use of personal protective equipment (PPE) to the handling of hazardous materials. Compliance is not optional; it’s a legal and moral imperative.

Strategies for Effective Implementation of Safety Protocols

Implementing safety protocols effectively requires a strategic approach. Here are key strategies:

– Risk assessment: Identify potential hazards.

– Protocol development: Create clear, actionable safety procedures.

– Resource allocation: Ensure availability of necessary safety equipment.

– Communication: Keep everyone informed about safety expectations.

These strategies form the foundation of a robust safety culture in heavy industries.

Training and Education: Empowering Employees for a Safer Workplace

Training and education are the cornerstones of workplace safety. They empower employees to:

– Recognize risks

– Use PPE correctly

– Respond to emergencies

– Advocate for safer work practices

Continuous training ensures that employees are up-to-date with the latest safety protocols and techniques.

Monitoring and Compliance: Ensuring Adherence to Regulations

Monitoring and compliance are critical for maintaining safety standards. Regular safety audits and inspections help in:

– Identifying non-compliance

– Addressing gaps in safety practices

– Reinforcing the importance of regulations

– Preventing accidents before they occur

These activities ensure that safety is not just a policy on paper but a practice in the field.

Continuous Improvement: Adapting to Changes in Health and Safety Standards

The world of health and safety is ever-evolving. Continuous improvement means:

– Staying informed about new regulations

– Updating protocols accordingly

– Encouraging feedback from employees

– Investing in new safety technologies

This proactive approach ensures that heavy industries remain at the forefront of safety compliance.

FAT FINGER plays a pivotal role in navigating health and safety regulations in heavy industries. Its digital solutions streamline the implementation, monitoring, and continuous improvement of safety protocols. With FAT FINGER, companies can:

– Build custom checklists and workflows

– Integrate safety protocols with daily operations

– Utilize AI coaching for better compliance

– Connect IoT devices for real-time monitoring

In conclusion, navigating health and safety regulations in heavy industries is a complex but essential task. It requires understanding the regulatory framework, implementing effective safety protocols, and ensuring continuous education and compliance. FAT FINGER’s innovative software solutions provide the tools needed to manage these challenges efficiently.

Sign up to FAT FINGER or request a demo today, and empower your team to achieve operational excellence while upholding the highest standards of health and safety.