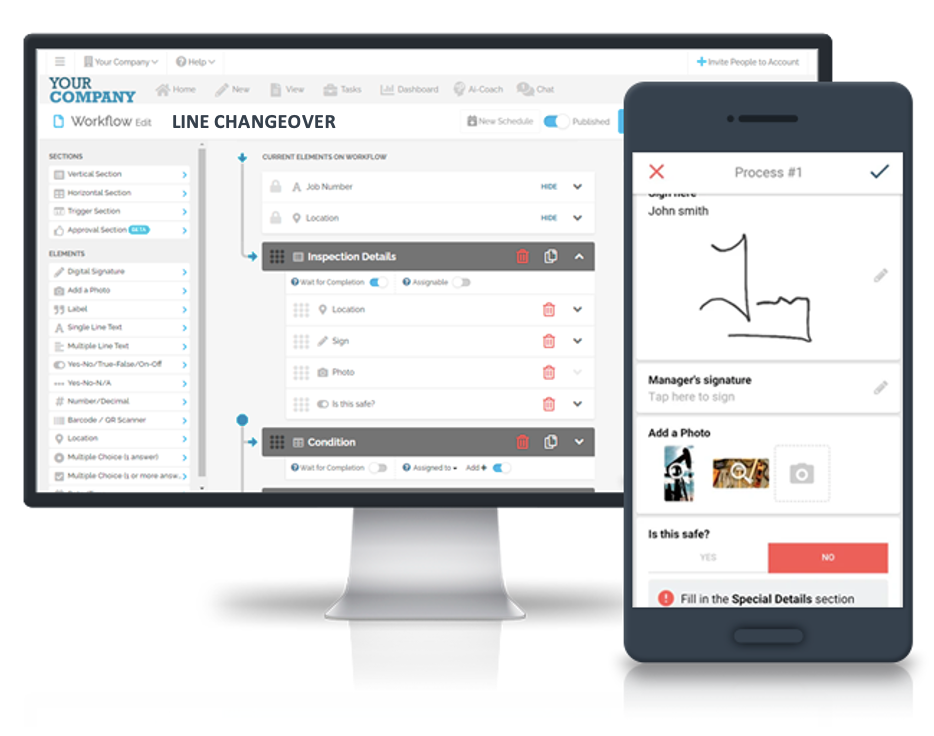

Industrial operations are a complex web of processes, each with its own set of challenges and requirements. One such critical process is the Line Changeover, a procedure that can significantly impact the efficiency and productivity of an operation. But how do you measure the success of a line changeover? This is where FAT FINGER comes into play. FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. With FAT FINGER, you can build digital line clearance procedures to facilitate seamless line changeovers. Production Managers have praised FAT FINGER as a game changer for their production line clearance process. Request a demo today to see how FAT FINGER can revolutionize your line changeover process.

Understanding Line Changeover

Line changeover, also known as line clearance, is the process of verifying that all line changeover activities have been completed and that the line is ready to resume production. The benefits of line clearance include reduced downtime, improved line efficiency, and increased product quality.

Measuring the Success of a Line Changeover

Measuring the success of a line changeover can be a complex task, but it is crucial for maintaining operational efficiency. Here are some key metrics to consider:

- Changeover Time: This is the time taken to switch from producing one product to another. A shorter changeover time indicates a more efficient process.

- Quality of Products: The quality of the products produced immediately after the changeover can indicate the success of the line clearance. High-quality products suggest a successful changeover.

- Downtime: This refers to the time during which the production line is not operational. Minimizing downtime is a key indicator of a successful line changeover.

How FAT FINGER Facilitates Successful Line Changeovers

FAT FINGER’s features, such as the Drag & Drop Workflow Builder, Mobile & Desktop Workflows, Dashboards, Integrations, Augmented Reality, Connect IoT Devices, and Artificial Intelligence Coaching, can significantly enhance the line changeover process. Here’s how:

- Streamlined Processes: FAT FINGER’s Drag & Drop Workflow Builder allows you to create custom workflows that streamline the line changeover process.

- Real-Time Monitoring: With FAT FINGER’s dashboards, you can monitor the line changeover process in real-time, enabling you to identify and address issues promptly.

- Improved Communication: FAT FINGER’s Mobile & Desktop Workflows facilitate seamless communication between team members, ensuring that everyone is on the same page during the line changeover process.

Conclusion

Measuring the success of a line changeover is crucial for maintaining operational efficiency in industrial operations. Key metrics such as changeover time, product quality, and downtime can provide valuable insights into the effectiveness of your line changeover process. With FAT FINGER, you can streamline this process, monitor it in real-time, and improve communication among team members, thereby enhancing the success of your line changeovers. Sign up for FAT FINGER today and unlock the potential of your line changeover process.

Discover how to effectively measure the success of a line changeover in industrial operations. Learn the key metrics, strategies, and tools that can help you optimize your processes and boost productivity. Don’t wait, start improving your operations today. Visit here for more information.