The oil and gas industry is a complex and high-risk sector that requires stringent safety measures and regular inspections. These inspections are crucial in ensuring the safety of workers, the environment, and the efficiency of operations. In this article, we will delve into the three main types of inspections in the oil and gas industry and how FAT FINGER, a digital workflow procedure builder, can streamline these processes.

1. Routine Inspections

Routine inspections are regular checks performed on equipment and facilities to ensure they are in good working condition. These inspections are typically scheduled based on the manufacturer’s recommendations or regulatory requirements. They involve checking for any visible signs of wear and tear, corrosion, leaks, or any other potential issues that could lead to equipment failure.

Inspectors regularly perform routine inspections on equipment and facilities to ensure they are in good working condition. Typically, these inspections are scheduled following the manufacturer’s recommendations or regulatory requirements. The process involves checking for any visible signs of wear and tear, corrosion, leaks, or any other potential issues that could lead to equipment failure.

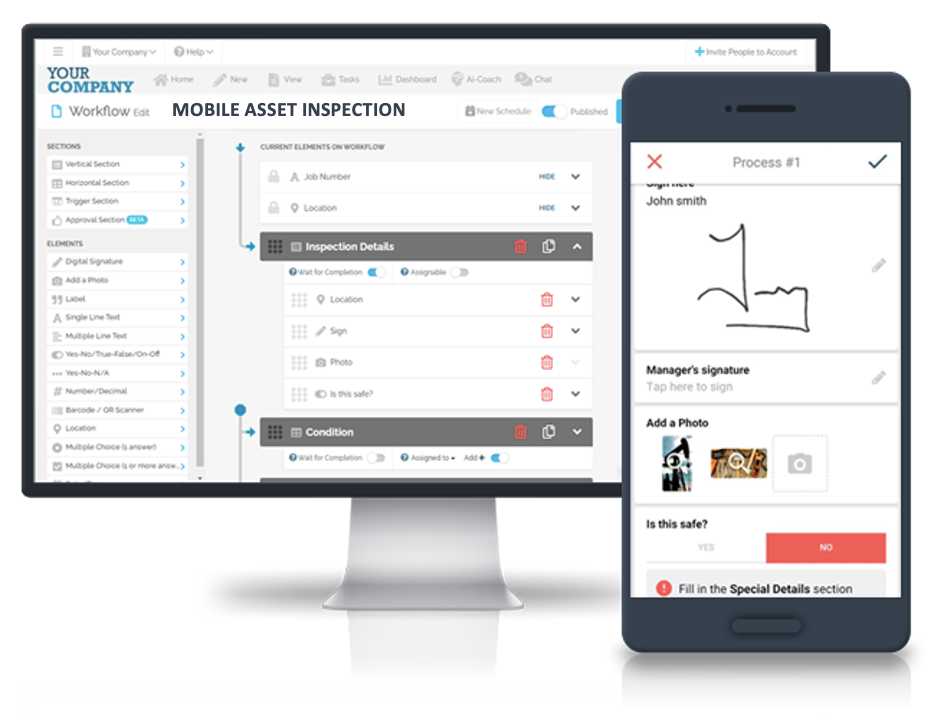

With FAT FINGER’s mobile asset inspection workflow, routine inspections can be conducted more efficiently. The software allows for easy monitoring of assets, preventing unwanted breakdowns and enhancing operational efficiency.

2. Predictive Inspections

Predictive inspections, also known as condition-based inspections, involve monitoring the condition of equipment and predicting when maintenance or replacement may be needed. This type of inspection relies heavily on data collected from sensors and other monitoring devices.

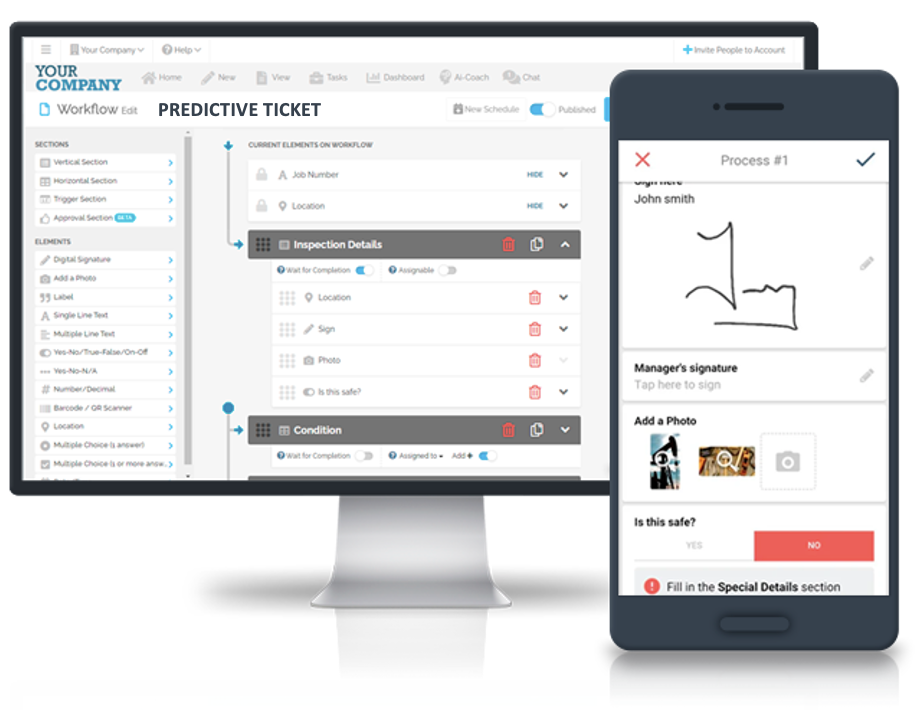

FAT FINGER’s integration capabilities and connection with IoT devices make predictive inspections more accurate and reliable. The software’s artificial intelligence coaching can also provide valuable insights and recommendations based on the collected data.

3. Compliance Inspections

Inspectors conduct compliance inspections to ensure that operations adhere to industry standards and regulations. These inspections involve checking safety measures, environmental impact, and the overall integrity of operations.

Inspections are crucial in avoiding legal issues, penalties, and potential shutdowns,

FAT FINGER’s dashboards provide a clear overview of compliance status, making it easier to identify areas that need improvement. The software’s drag and drop workflow builder also allows for the creation of custom workflows that align with specific compliance requirements.

Why Choose FAT FINGER for Oil and Gas Inspections?

FAT FINGER’s digital workflows offer a comprehensive solution for managing inspections in the oil and gas industry. The software’s features, including mobile and desktop workflows, dashboards, integrations, augmented reality, IoT device connection, and artificial intelligence coaching, provide a robust platform for conducting routine, predictive, and compliance inspections.

With FAT FINGER, you can build mobile asset inspection workflows that help you monitor assets accurately and prevent unwanted breakdowns. The software’s user-friendly interface and advanced features make it an ideal choice for businesses looking to improve their inspection processes and ensure the safety and efficiency of their operations.

Experience the benefits of FAT FINGER’s digital workflows for yourself. Request a demo today and see how FAT FINGER can revolutionize your inspection processes.

Conclusion

In the high-risk oil and gas industry, regular and thorough inspections are crucial. Routine, predictive, and compliance inspections each play a vital role in maintaining the safety and efficiency of operations. With FAT FINGER’s digital workflows, these inspections can be conducted more efficiently and accurately, ensuring that your operations remain safe, compliant, and productive.

Ready to take your inspection processes to the next level? Create a mobile asset inspection workflow for free on FAT FINGER and experience the difference today.