Line changeovers in hazardous environments present a unique set of challenges that require meticulous planning, stringent safety measures, and efficient execution. In this article, we will delve into these challenges and explore how innovative solutions like FAT FINGER can help overcome them. FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence. Request a demo today to see how FAT FINGER can revolutionize your line changeover process.

Understanding the Challenges

Line changeovers in hazardous environments are fraught with potential risks and complications. These challenges can be broadly categorized into three areas:

- Safety Concerns: The inherent risks associated with hazardous environments make safety a paramount concern during line changeovers. This includes the risk of chemical exposure, fires, explosions, and other potential hazards.

- Operational Efficiency: Line changeovers can be time-consuming and complex, leading to significant downtime and loss of productivity. The challenge lies in minimizing downtime without compromising safety.

- Regulatory Compliance: Hazardous environments are subject to stringent regulations to ensure worker safety and environmental protection. Compliance with these regulations is crucial during line changeovers.

Case Study: The Oil and Gas Industry

The oil and gas industry provides a prime example of the challenges associated with line changeovers in hazardous environments. According to a report by the U.S. Bureau of Labor Statistics, the oil and gas extraction industry has a fatality rate seven times higher than the average for all industries. This underscores the critical need for effective safety measures during line changeovers.

How FAT FINGER Can Help

FAT FINGER offers a suite of features designed to address the challenges of line changeovers in hazardous environments. These include:

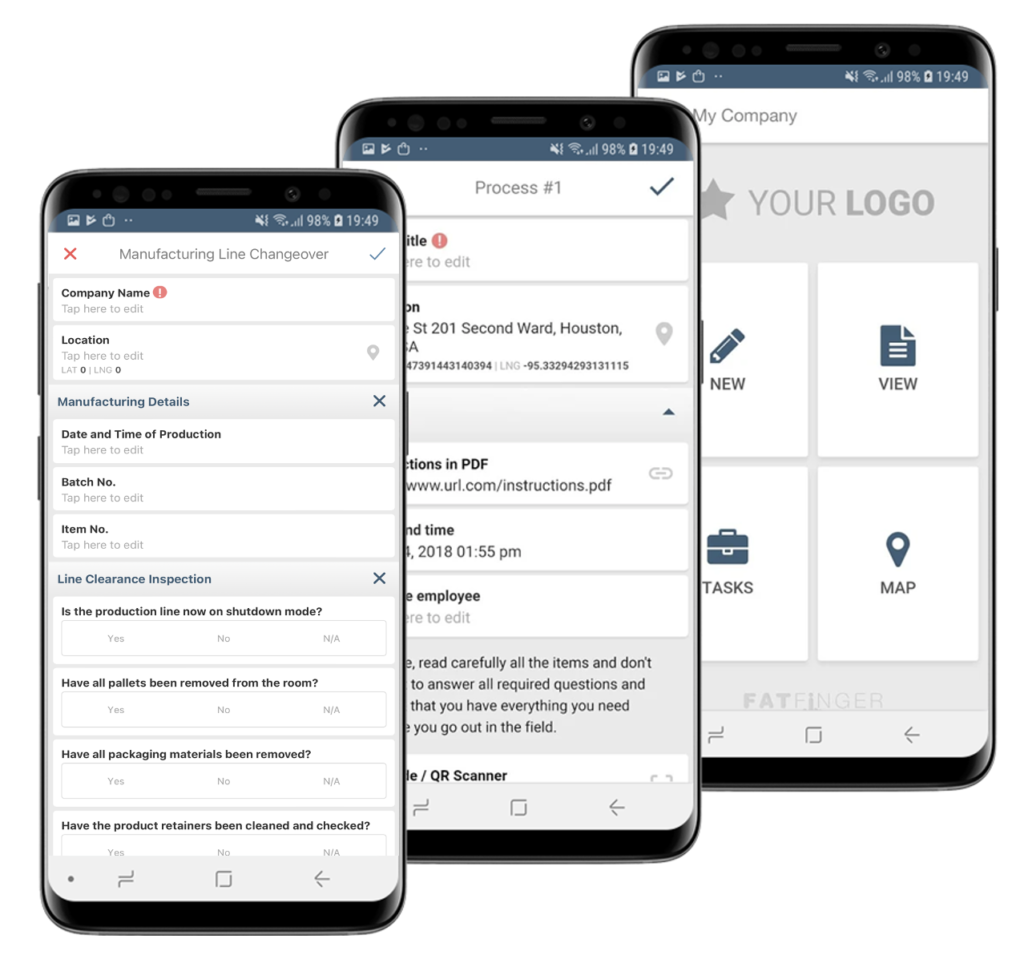

- Drag & Drop Workflow Builder: This feature allows you to create custom workflows for line changeovers, ensuring that all necessary steps are followed in the correct order.

- Mobile & Desktop Workflows: FAT FINGER’s workflows can be accessed from any device, allowing your team to stay connected and informed during the line changeover process.

- Artificial Intelligence Coaching: FAT FINGER’s AI coaching provides real-time guidance to your team, helping to prevent errors and enhance safety.

With FAT FINGER, you can build digital workflow procedures across a range of safety, operations, and maintenance solutions, including line changeovers. This ensures that your team is equipped with the tools and information they need to perform their work safely and efficiently.

Conclusion

Line changeovers in hazardous environments present a host of challenges, from safety concerns to operational efficiency and regulatory compliance. However, with the right tools and procedures in place, these challenges can be effectively managed. FAT FINGER’s digital workflow procedure builder offers a powerful solution, enabling your team to perform line changeovers safely, efficiently, and in compliance with all relevant regulations. By leveraging FAT FINGER’s innovative features, you can transform your line changeover process and unlock operational excellence.

Ready to take the next step? Sign up for FAT FINGER today and revolutionize your line changeover process.