As the energy sector continues to evolve, power plants are increasingly seeking innovative solutions to streamline their operations. One area that has been a significant challenge is inventory and asset management. This is where FAT FINGER comes into play. FAT FINGER is a digital workflow procedure builder that allows you to create checklists, workflows, and digital procedures that unlock operational excellence. In this article, we will delve into how FAT FINGER can revolutionize inventory and asset management in power plants. But first, why not schedule a demo to see FAT FINGER in action?

Understanding the Challenges of Inventory and Asset Management in Power Plants

Before we delve into the solutions, it’s crucial to understand the challenges that power plants face in managing their inventory and assets.

One of the significant challenges is tracking the location and status of assets. In a power plant, there are countless pieces of equipment, machinery, and tools that must be tracked. If an asset is lost or misplaced, it can lead to significant delays and inefficiencies. Furthermore, if the status of an asset (whether it is in use, in need of repair, or available) is not correctly tracked, it can lead to further inefficiencies and potential accidents if faulty equipment is used.

Ensuring timely maintenance is another challenge. Power plants are complex operations with a multitude of machines and systems that need regular maintenance to function optimally. Without a robust system to schedule and track this maintenance, machinery can break down, leading to costly repairs and downtime.

Managing spare parts inventory is also a crucial part of inventory and asset management. Power plants must have the necessary parts on hand to repair or replace equipment as needed. However, maintaining a stock of spare parts can be costly, and if not managed effectively, can lead to an overstock of some parts and a shortage of others.

In addition to these operational challenges, power plants also need to ensure compliance with safety and environmental regulations. These regulations are designed to protect the safety of workers and the surrounding environment. Non-compliance can result in hefty fines, damage to the power plant’s reputation, and potential legal action.

These challenges, if not properly addressed, can lead to increased operational costs. For instance, lost or misplaced assets need to be replaced, machinery breakdowns require expensive repairs, and an overstock of spare parts ties up capital that could be used elsewhere. Furthermore, these challenges can lead to reduced efficiency as workers spend time searching for assets or waiting for machinery to be repaired. They can also pose potential safety risks if faulty equipment is used, or if safety regulations are not followed.

In conclusion, understanding these challenges is the first step in finding effective solutions to improve inventory and asset management in power plants. The next step involves exploring strategies and technologies that can help power plants overcome these challenges to increase efficiency, reduce operational costs, and ensure safety.

Introducing FAT FINGER: A Game-Changer in Inventory and Asset Management

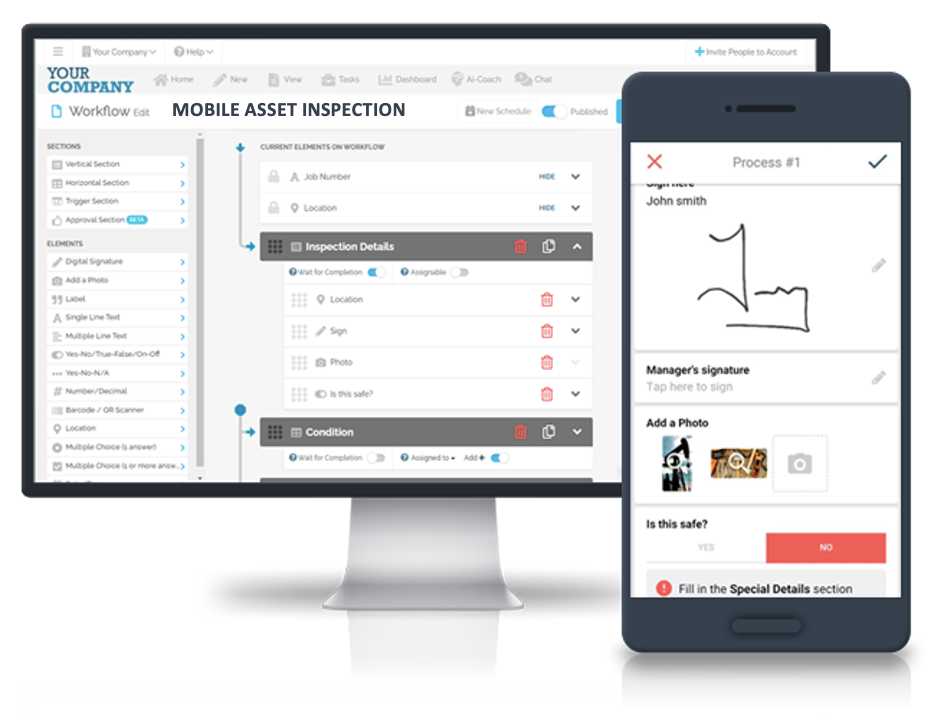

FAT FINGER is designed to address these challenges head-on. With features like a drag and drop workflow builder, augmented reality, AI Coach, IoT device connectivity, integrations, mobile and desktop workflows, and dashboards, FAT FINGER provides a comprehensive solution for inventory and asset management in power plants.

Drag and Drop Workflow Builder

The drag and drop workflow builder allows you to create custom workflows for managing your assets and inventory. For example, you can create a workflow for tracking the location and status of assets, scheduling maintenance tasks, and managing spare parts inventory. This not only streamlines the process but also reduces the risk of errors and oversights.

Augmented Reality and AI Coach

With augmented reality, you can visualize your assets in a 3D environment, making it easier to locate and inspect them. The AI Coach feature, on the other hand, provides real-time guidance and recommendations, helping you make informed decisions about your assets and inventory.

IoT Device Connectivity and Integrations

FAT FINGER’s ability to connect to IoT devices allows you to monitor your assets in real-time, ensuring timely maintenance and reducing the risk of breakdowns. The software also integrates with other systems, allowing you to manage your assets and inventory from a single platform.

Case Study: How FAT FINGER Streamlined Inventory and Asset Management in a Power Plant

To illustrate the effectiveness of FAT FINGER, let’s look at a case study of a power plant that implemented the software. The plant was struggling with tracking the location and status of its assets, managing spare parts inventory, and ensuring compliance with safety regulations. After implementing FAT FINGER, the plant was able to streamline these processes, resulting in a 30% reduction in operational costs and a significant improvement in safety compliance.

Conclusion

Inventory and asset management in power plants can be a complex and challenging task. However, with the right tools, it can be streamlined and made more efficient. FAT FINGER, with its robust features and capabilities, provides a comprehensive solution for managing assets and inventory in power plants. By implementing FAT FINGER, power plants can reduce operational costs, improve efficiency, and ensure safety compliance.

So why wait? Build a digital workflow for free on FAT FINGER or schedule a demo today!