As we navigate the rapidly evolving landscape of technology, one thing is clear: the future of work is here, and it’s digital. One of the most exciting developments in this arena is the integration of autonomous vehicles into facility operations. This article will explore how this technology is revolutionizing the way we work, and how software like FAT FINGER is playing a pivotal role in this transformation.

Are you ready to embrace the future of work? Request a demo of FAT FINGER today and discover how you can build digital workflow procedures to improve your facility inspections and production rounds.

Autonomous Vehicles: A Game Changer for Facility Operations

Autonomous vehicles, also known as self-driving cars, are no longer a futuristic concept. They’re here, and they’re transforming the way we operate facilities. These vehicles can perform tasks without human intervention, making them a valuable asset in various industries, from manufacturing to logistics and beyond.

Benefits of Integrating Autonomous Vehicles into Facility Operations

Integrating autonomous vehicles into facility operations offers numerous benefits:

- Increased efficiency: Autonomous vehicles can operate 24/7 without breaks, significantly increasing productivity.

- Improved safety: These vehicles can perform dangerous tasks, reducing the risk of accidents and injuries.

- Cost savings: By automating tasks, companies can save on labor costs and reduce operational expenses.

The Role of FAT FINGER in the Integration of Autonomous Vehicles

FAT FINGER, a digital workflow procedure builder, is at the forefront of this technological revolution. This software empowers front-line teams to do their work correctly every time by allowing you to build checklists, workflows, and digital procedures that unlock operational excellence.

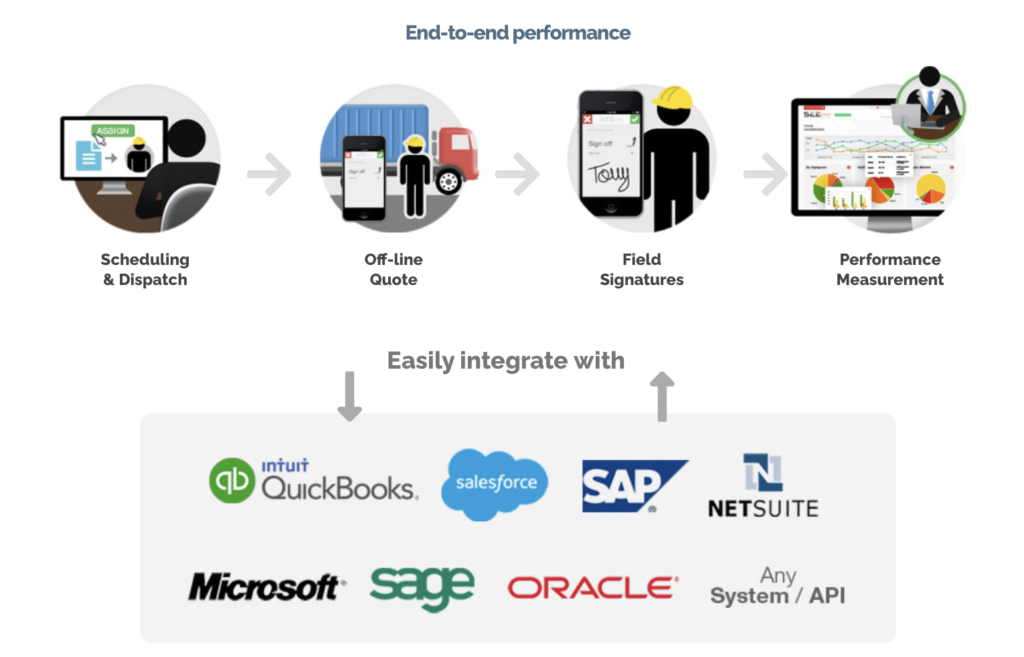

With features like a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and artificial intelligence coaching, FAT FINGER is the perfect tool to streamline your facility operations and integrate autonomous vehicles effectively.

Case Study: Improving Facility Inspections with FAT FINGER

Facility inspections are a critical part of maintaining a safe and functional facility. By using FAT FINGER, you can build comprehensive inspection checklists that can help keep your facility in good condition and avoid costly repairs or downtime.

For instance, a manufacturing company used FAT FINGER to create a digital workflow for their facility inspections. This allowed them to automate the inspection process, reducing errors and improving efficiency. The company was able to save significant time and resources, demonstrating the power of digital workflow procedures in facility operations.

Conclusion: Embrace the Future of Work with FAT FINGER

The integration of autonomous vehicles into facility operations is a game-changer, offering increased efficiency, improved safety, and cost savings. As we move towards a more digital future, software like FAT FINGER will play an increasingly important role in helping businesses adapt and thrive.

With its powerful features and user-friendly interface, FAT FINGER empowers front-line teams to do their work correctly every time, making it an invaluable tool for any business looking to improve their facility operations and embrace the future of work.

Are you ready to take the next step towards operational excellence? Sign up for FAT FINGER today and start building digital workflow procedures that will revolutionize your facility operations.

Discover the future of work by integrating autonomous vehicles into your facility operations. Learn more about how this innovative technology can streamline your operations and increase efficiency. Visit fatfinger.io today to get started.