Standard Operating Procedures (SOPs) are the backbone of any successful energy plant operation. They ensure consistency, efficiency, and safety in all processes. However, the traditional paper-based SOPs are becoming increasingly outdated and inefficient. This is where FAT FINGER comes in. FAT FINGER is a digital workflow procedure builder that allows you to create checklists, workflows, and digital procedures that unlock operational excellence.

In this article, we will delve into how you can implement SOPs in energy plants using custom FAT FINGER apps. Request a demo to see how FAT FINGER can revolutionize your energy plant operations.

Understanding FAT FINGER

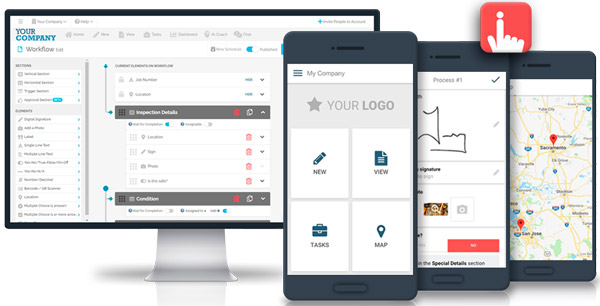

FAT FINGER is a cutting-edge software solution designed to streamline operations in various industries, including energy plants. It allows you to digitize your SOPs, making them more accessible, efficient, and easy to update. Here are some of the key features of FAT FINGER:

- Real-time data collection and analysis

- Customizable digital forms and checklists

- Automated workflows

- AI Coach

- Augmented reality

- Works on desktop and mobile

- Comprehensive reporting and analytics

Implementing SOPs in Energy Plants with FAT FINGER

Implementing SOPs in energy plants using FAT FINGER is a straightforward process. Here’s how you can do it:

1. Digitize Your SOPs

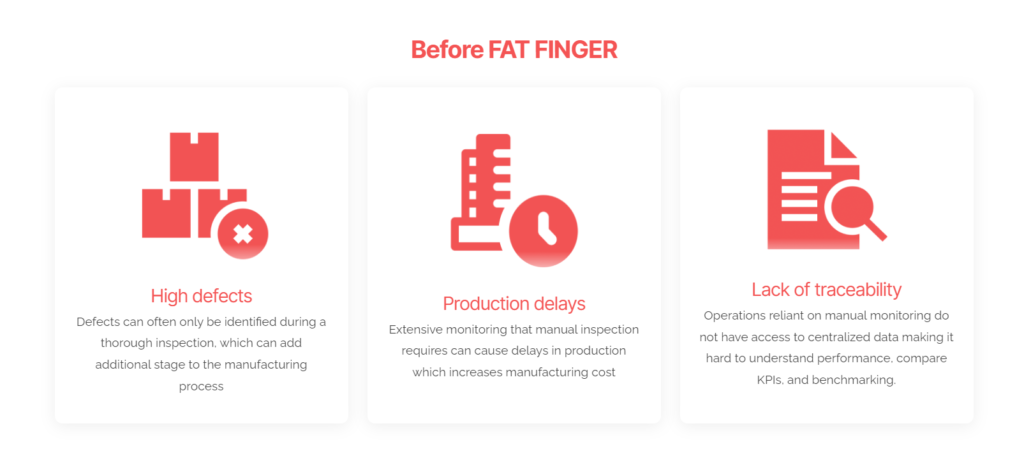

With FAT FINGER, you can easily convert your paper-based SOPs into digital formats. This not only makes them more accessible but also ensures that they are always up-to-date.

2. Customize Your Digital Forms

FAT FINGER allows you to customize your digital forms and checklists to suit your specific needs. This ensures that your SOPs are tailored to your energy plant’s unique requirements.

3. Automate Your Workflows

With FAT FINGER, you can automate your workflows, ensuring that all processes are carried out consistently and efficiently. This reduces the risk of human error and increases overall productivity.

4. Monitor Your Operations in Real-Time

FAT FINGER provides real-time data collection and analysis, allowing you to monitor your operations in real-time. This enables you to identify and address any issues promptly, ensuring optimal performance at all times.

Benefits of Using FAT FINGER in Energy Plants

Implementing SOPs in energy plants using FAT FINGER offers numerous benefits. These include:

- Increased efficiency: By digitizing and automating your SOPs, you can significantly increase your energy plant’s efficiency.

- Improved safety: FAT FINGER’s real-time monitoring and instant alerts ensure that any safety issues are promptly identified and addressed.

- Reduced costs: By streamlining your operations, FAT FINGER can help reduce operational costs.

- Enhanced compliance: FAT FINGER’s comprehensive reporting and analytics ensure that you are always in compliance with industry regulations.

Conclusion

Implementing SOPs in energy plants using custom FAT FINGER apps can revolutionize your operations, making them more efficient, safe, and cost-effective. With its customizable digital forms, automated workflows, real-time monitoring, and comprehensive reporting, FAT FINGER is the ideal solution for any energy plant looking to optimize its operations.

Ready to experience the benefits of FAT FINGER for yourself? Build a digital workflow for free on FAT FINGER or schedule a demo today!