Lean manufacturing is a systematic method for waste minimization within a manufacturing system without sacrificing productivity. It can be a game-changer for businesses looking to improve efficiency, reduce waste, and increase profitability. But how can you effectively implement these principles in your organization?

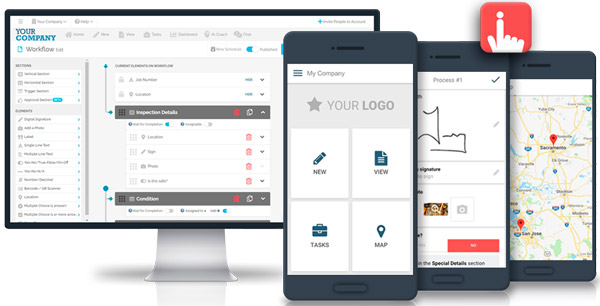

Enter FAT FINGER, a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. With features like a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and artificial intelligence coaching, FAT FINGER is the perfect tool to help you implement lean manufacturing principles.

Request a demo today to see how FAT FINGER can revolutionize your manufacturing processes.

Understanding Lean Manufacturing Principles

Before we delve into how FAT FINGER can help, it’s important to understand the core principles of lean manufacturing. These principles include:

- Identifying value from the customer’s perspective

- Mapping the value stream and eliminating waste

- Creating flow by ensuring smooth transitions and processes

- Establishing a pull system where production is based on customer demand

- Striving for perfection through continuous improvement

How FAT FINGER Facilitates Lean Manufacturing

Now that we understand the principles of lean manufacturing, let’s explore how FAT FINGER can facilitate their implementation.

1. Identifying Value

FAT FINGER’s AI coaching feature can help identify areas of value in your manufacturing process. By analyzing data from your workflows, it can provide insights into what processes are most valuable to your customers, helping you focus your efforts where they matter most.

2. Mapping the Value Stream

With FAT FINGER’s drag & drop workflow builder, you can easily map out your value stream. This visual representation of your processes allows you to identify areas of waste and inefficiency, making it easier to eliminate them.

3. Creating Flow

FAT FINGER’s mobile and desktop workflows ensure a smooth flow of processes. By digitizing your workflows, you can eliminate bottlenecks and ensure that each step in your process seamlessly transitions to the next.

4. Establishing a Pull System

FAT FINGER’s dashboards and integrations allow you to establish a pull system. By integrating with your existing systems, you can ensure that production is based on real-time customer demand, reducing waste and improving efficiency.

5. Striving for Perfection

Finally, FAT FINGER’s continuous improvement features help you strive for perfection. By providing real-time feedback and analytics, you can continuously monitor and improve your processes, driving towards operational excellence.

Case Study: Lean Manufacturing with FAT FINGER

Let’s look at a real-world example of how FAT FINGER can facilitate lean manufacturing. A manufacturing company used FAT FINGER to digitize their workflows, resulting in a 30% reduction in waste and a 20% increase in productivity. By identifying areas of value, mapping their value stream, creating flow, establishing a pull system, and striving for perfection, they were able to significantly improve their operations and bottom line.

Conclusion

Implementing lean manufacturing principles can be a complex task, but with the right tools, it becomes significantly easier. FAT FINGER’s digital workflow procedure builder is designed to empower front-line teams and unlock operational excellence, making it the perfect tool for implementing lean manufacturing principles.

With features like AI coaching, a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, and continuous improvement capabilities, FAT FINGER can help you reduce waste, improve efficiency, and increase profitability.

Ready to see how FAT FINGER can revolutionize your manufacturing processes? Build a digital workflow for free on FAT FINGER or schedule a demo today.