As the manufacturing industry continues to evolve, the Internet of Things (IoT) is playing an increasingly significant role in enhancing efficiency and productivity. IoT, a network of interconnected devices that communicate and exchange data, is revolutionizing the manufacturing sector by providing real-time insights, improving Operational Efficiency, and reducing costs. One such tool that is making this possible is FAT FINGER, a digital workflow procedure builder that empowers front-line teams to do their work correctly every time.

The Role of IoT in Manufacturing

IoT in manufacturing, often referred to as the Industrial Internet of Things (IIoT), involves the use of smart sensors and actuators to enhance manufacturing and industrial processes. It provides manufacturers with a wealth of data that can be used to improve efficiency, reduce waste, and increase profitability.

Real-Time Monitoring and Predictive Maintenance

One of the most significant benefits of implementing IoT in manufacturing is the ability to monitor equipment and processes in real-time. This allows for Predictive Maintenance, where potential issues can be identified and addressed before they result in costly downtime. For example, sensors can detect when a machine is overheating or vibrating excessively, indicating a potential problem.

Improved Efficiency and Productivity

IoT can also improve efficiency and productivity by automating routine tasks. For instance, IoT devices can automatically adjust machine settings based on real-time data, reducing the need for manual intervention and increasing overall productivity.

Case Study: FAT FINGER and IoT in Manufacturing

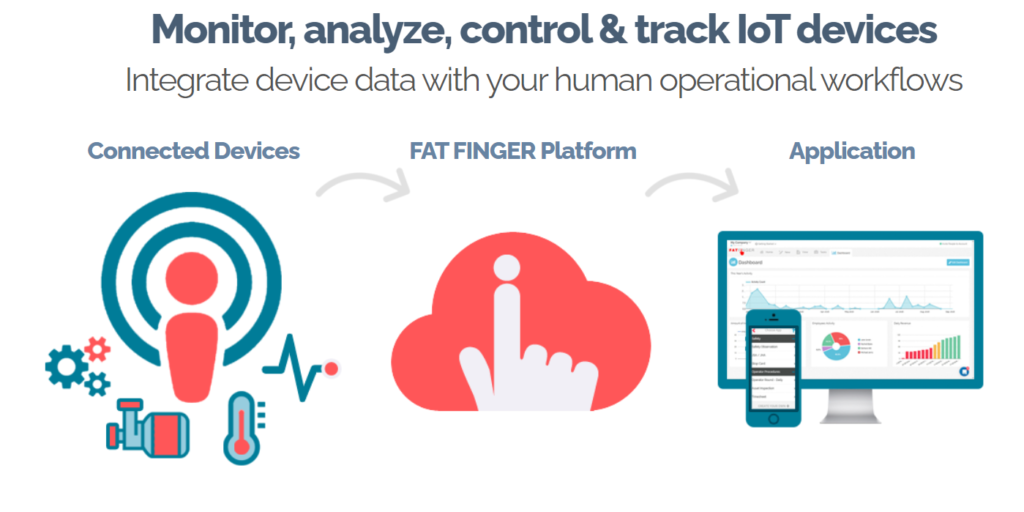

FAT FINGER is a prime example of how IoT can be effectively implemented in manufacturing. This digital workflow procedure builder allows front-line teams to build checklists, workflows, and digital procedures that unlock operational excellence. With features like a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and artificial intelligence coaching, FAT FINGER is transforming the way manufacturing companies operate.

How FAT FINGER Enhances Efficiency

FAT FINGER’s IoT connectivity allows for real-time data collection and analysis. This data can be used to identify inefficiencies, predict potential issues, and make informed decisions. For example, if a machine is operating outside of its optimal parameters, FAT FINGER can alert the relevant personnel, allowing them to address the issue before it results in downtime.

Augmented Reality and AI Coaching

With its augmented reality feature, FAT FINGER allows users to visualize data and workflows in a whole new way. This can greatly enhance understanding and efficiency. Additionally, FAT FINGER’s AI coaching feature provides guidance and support to front-line teams, helping them to perform their tasks correctly every time.

Conclusion

Implementing IoT in manufacturing is no longer a luxury but a necessity for companies looking to stay competitive in today’s fast-paced, data-driven world. With tools like FAT FINGER, manufacturers can harness the power of IoT to improve efficiency, reduce waste, and increase profitability. By providing real-time insights, automating routine tasks, and offering innovative features like augmented reality and AI coaching, FAT FINGER is truly a game-changer in the manufacturing industry.

Ready to unlock operational excellence with FAT FINGER? Sign up today or request a demo to see how FAT FINGER can transform your manufacturing processes.