As we navigate the digital age, data-driven decisions have become the cornerstone of successful businesses. One of the most powerful tools in this data-driven arsenal is predictive analytics. This article will demystify How Predictive Analytics Works and how it can be leveraged to make informed decisions. We will also introduce you to FAT FINGER, a digital workflow procedure builder that empowers front-line teams to work efficiently and accurately every time. With FAT FINGER, you can build predictive maintenance digital workflows that ensure problems are addressed even before they start. Ready to dive in? Let’s get started, or schedule a demo to see FAT FINGER in action.

Understanding Predictive Analytics

Predictive analytics is a branch of advanced analytics that uses historical data, statistical algorithms, and machine learning techniques to predict future outcomes. It provides estimates about the likelihood of a future outcome. It’s like having a crystal ball, but one that’s powered by data and algorithms instead of magic.

How Predictive Analytics Works

Predictive analytics works by extracting information from existing data sets to determine patterns and predict future outcomes and trends. It does not tell you what will happen in the future; instead, it forecasts what might happen with an acceptable level of reliability.

Steps in Predictive Analytics

- Data Collection: The process begins with collecting data from various sources. This could be customer data, operational data, financial data, and more.

- Data Analysis: The collected data is then analyzed to identify patterns and trends.

- Statistical Analysis: Using statistical algorithms, the data is further analyzed to identify significant predictors.

- Modeling: A predictive model is then created and tested.

- Deployment: Once the model is fine-tuned, it is deployed to make predictions.

- Model Monitoring: The model is monitored and adjusted as needed to ensure it remains accurate.

Predictive Analytics in Action: FAT FINGER

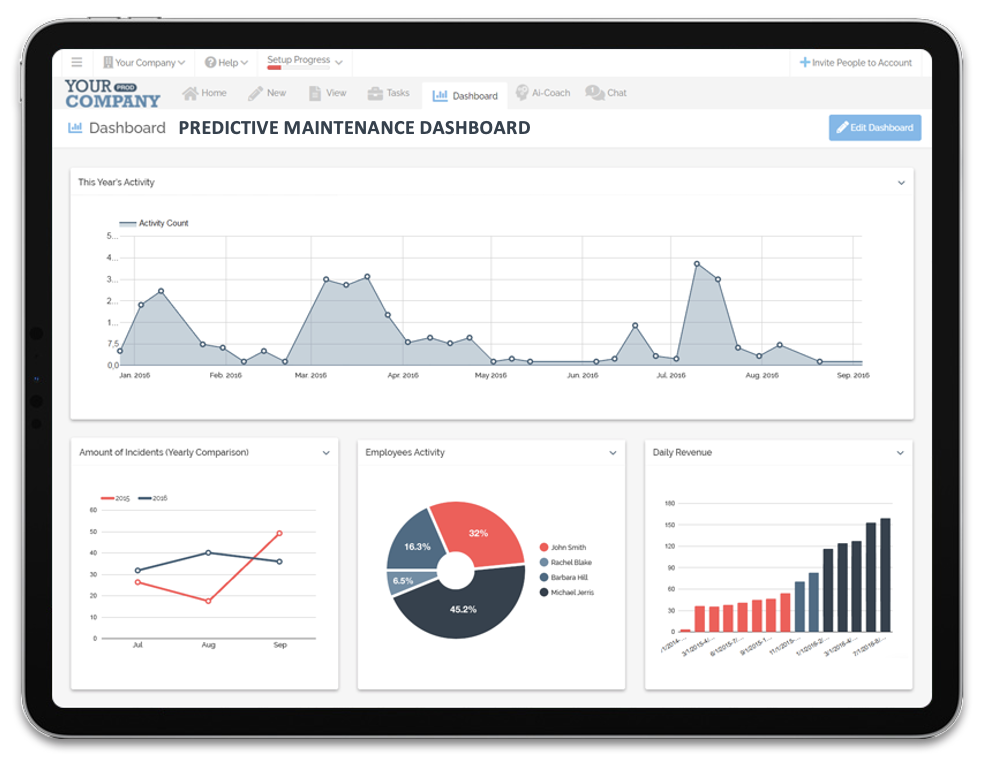

One of the most practical applications of predictive analytics is in predictive maintenance. This is where FAT FINGER comes into play. FAT FINGER allows you to build predictive maintenance digital workflows that can accurately determine when maintenance needs to be completed to prevent costly breakdowns.

Instead of having scheduled maintenance done on a predetermined timeframe, predictive maintenance uses data and technology to specify when maintenance needs to be completed. It works by collecting data from a facility’s various components and then using it to determine when parts need maintenance. If necessary, it can also use algorithms or Artificial Intelligence (AI).

Predictive maintenance can help save time and money, improve efficiency in the facility, and help ensure that safety standards are adhered to throughout the lifecycle of all machines.

Conclusion

Predictive analytics is a powerful tool that can help businesses make data-driven decisions. By analyzing historical data and identifying patterns, predictive analytics can provide valuable insights into future outcomes. When applied to predictive maintenance, as with FAT FINGER, it can help prevent costly breakdowns and improve efficiency. Ready to leverage the power of predictive analytics in your business? Create a predictive maintenance workflow for free on FAT FINGER or schedule a demo today.

Discover the power of predictive analytics in data-driven decisions. Uncover the mystery of how it works and how it can benefit your business. Don’t wait, Schedule a Demo today and take the first step towards a data-driven future.