In the fast-paced world of modern manufacturing, efficiency and precision are paramount. Enter FAT FINGER, a digital workflow procedure builder that empowers front-line teams to execute their tasks flawlessly every time. By enabling the creation of checklists, workflows, and digital procedures, FAT FINGER unlocks operational excellence. Its features, including a drag-and-drop workflow builder, mobile and desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and AI coaching, make it a powerhouse in the manufacturing sector.

Exploring the Range of FAT FINGER’s Integration Capabilities

FAT FINGER’s integration capabilities are vast and versatile. They seamlessly connect with a variety of systems, including ERP, CRM, and SCM platforms. This interoperability allows for real-time data exchange and process automation. FAT FINGER’s API also supports custom integrations, ensuring that even the most unique manufacturing environments can benefit from its features. The result is a cohesive ecosystem where information flows smoothly, and decision-making is data-driven.

Enhancing Efficiency: How FAT FINGER Integrations Optimize Workflow

Integrations by FAT FINGER streamline manufacturing operations in several ways. They automate routine tasks, reducing the risk of human error. Real-time data syncing ensures that all stakeholders have access to the latest information. FAT FINGER’s AI coaching guides workers through complex procedures, boosting productivity. These integrations also facilitate predictive maintenance, minimizing downtime. Overall, FAT FINGER’s integrations are a catalyst for enhanced efficiency.

Case Studies: Success Stories of Manufacturing Operations Using FAT FINGER

Numerous manufacturing operations have reaped the benefits of FAT FINGER. One such success story involves a company that reduced its incident rates by 30% after implementing FAT FINGER’s safety checklists. Another enterprise increased its production output by 20% through optimized workflows. These case studies exemplify how FAT FINGER’s integrations can lead to tangible improvements in manufacturing performance.

Overcoming Challenges: The Role of FAT FINGER in Problem-Solving and Continuous Improvement

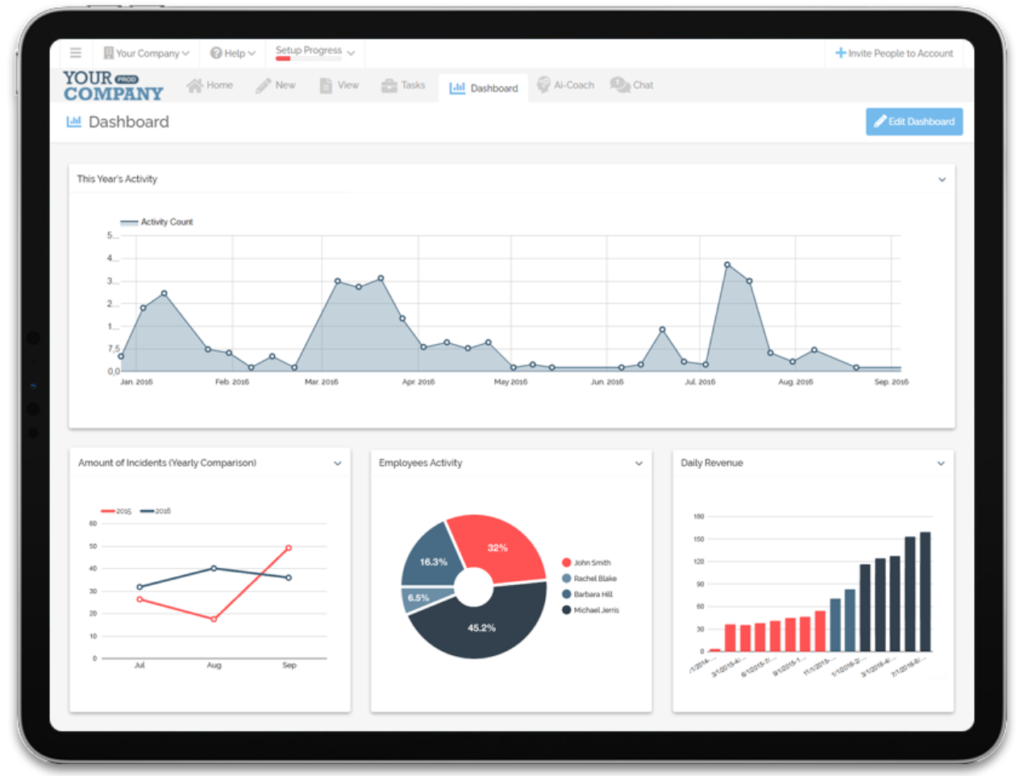

FAT FINGER plays a crucial role in addressing manufacturing challenges. Its dashboards provide insights into process bottlenecks, enabling targeted improvements. The software’s flexibility allows for rapid adaptation to changing demands. FAT FINGER’s integrations also support continuous improvement initiatives, fostering a culture of excellence. By leveraging FAT FINGER, manufacturers can turn obstacles into opportunities for growth.

The Future of Manufacturing: Predicting Trends with FAT FINGER’s Evolving Integrations

As manufacturing evolves, so do FAT FINGER’s integrations. They are poised to incorporate advanced technologies like machine learning and blockchain. These developments will further enhance traceability and smart automation. FAT FINGER’s commitment to innovation suggests that it will remain at the forefront of manufacturing trends, helping businesses stay competitive in a dynamic landscape.

FAT FINGER is revolutionizing manufacturing operations with its robust integrations. By streamlining workflows, enhancing efficiency, and fostering continuous improvement, FAT FINGER is an indispensable tool for modern manufacturers. To experience the transformative power of FAT FINGER, sign up or request a demo today. Embrace operational excellence and propel your manufacturing processes into the future.