As we navigate the digital age, the importance of data in decision-making processes cannot be overstated. The ability to collect, analyze, and interpret data is crucial for businesses to stay competitive. This is where digitalization comes in, and more specifically, where FAT FINGER, a digital workflow procedure builder, plays a pivotal role.

Understanding the Power of Digitalization

Digitalization is the process of converting information into a digital format. This process allows businesses to streamline their operations, improve efficiency, and make more informed decisions. With digitalization, businesses can collect and analyze data in real-time, enabling them to respond to market changes swiftly and effectively.

The Role of FAT FINGER in Digitalization

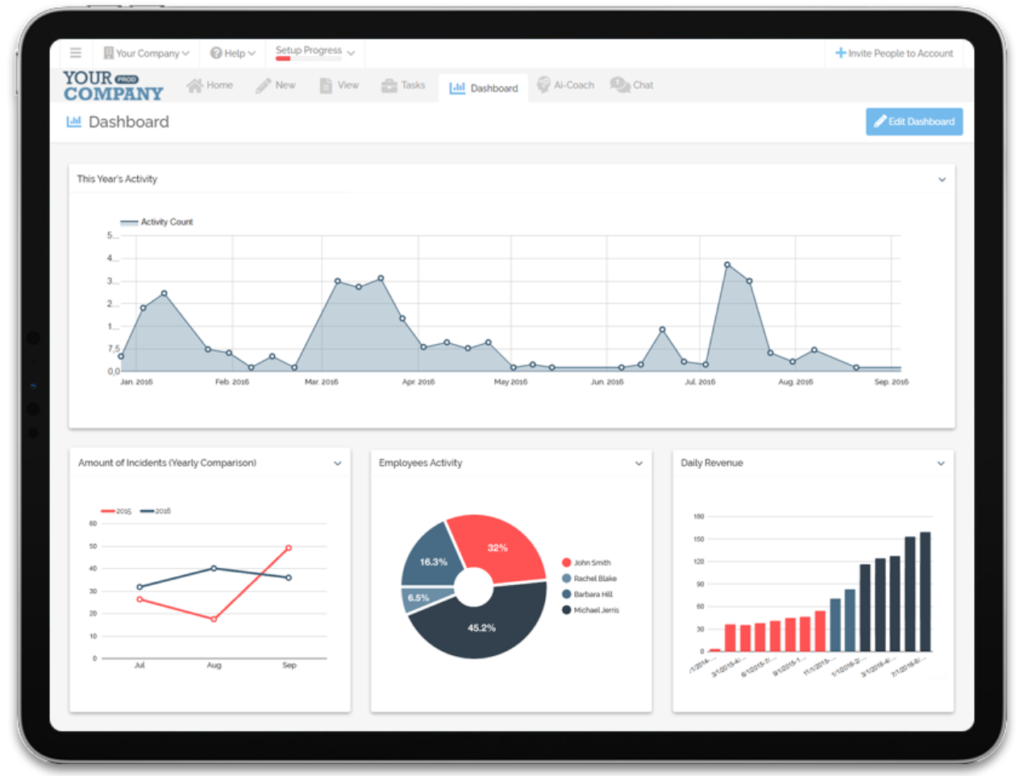

FAT FINGER empowers front-line teams to do their work correctly every time by allowing them to build checklists, workflows, and digital procedures that unlock operational excellence. With features like Drag & Drop Workflow Builder, Mobile & Desktop Workflows, Dashboards, Integrations, Augmented Reality, Connect IoT Devices, and Artificial Intelligence Coaching, FAT FINGER is a game-changer in the digitalization process.

How FAT FINGER Bridges the Gap Between Data and Decision Making

FAT FINGER’s digital workflows and checklists across safety, maintenance, and operations areas provide a wealth of data that can be used to make informed decisions. Here are some of the solutions FAT FINGER offers:

- Safety: Take 5 Safety, Near miss reporting, JSA / JHA, Risk Assessment, Incident reporting, Journey report

- Operations: Material Inspection, Quality Control, Shift Handover, Facility inspection / Production rounds, Line Changeover, Field ticket

- Maintenance: Work Order Checklist, Truck inspection checks, Mobile Asset Inspection, Shutdown / Turnaround form, Preventive maintenance inspection, Predictive Maintenance

By digitizing these processes, FAT FINGER allows businesses to collect and analyze data in real-time, leading to more informed decision-making.

Case Study: The Impact of FAT FINGER on Decision Making

Consider a manufacturing company that implemented FAT FINGER’s digital workflows and checklists. The company was able to collect data on every aspect of their operations, from safety incidents to quality control checks. This data was then analyzed and used to make decisions about improving safety protocols, streamlining operations, and enhancing product quality. As a result, the company saw a significant reduction in safety incidents and an increase in product quality and operational efficiency.

Conclusion: The Power of Digitalization in Decision Making

In conclusion, digitalization, with the help of tools like FAT FINGER, bridges the gap between data and decision making. By digitizing workflows and checklists, businesses can collect and analyze data in real-time, leading to more informed and effective decision-making. Whether it’s improving safety protocols, streamlining operations, or enhancing product quality, the power of digitalization in decision making cannot be overstated.

Ready to unlock the power of digitalization in your business? Discover how digitalization bridges the gap between data and decision making. Leverage the power of technology to transform raw data into actionable insights.