A Job Hazard Analysis (JHA), also known as hazard identification, is a tool for performing hazard assessments. JHA is essential for identifying potential risks in the workplace and taking steps to mitigate those risks.

This article aims to provide measures to perform job hazard analysis effectively and how technology can help reduce or eliminate those hazards.

Table of Contents:

I. What is Job Hazard Analysis?

III. Common Challenges to an Effective Job Hazard Analysis

III. Why is JHA Important?

IV. How to Effectively Perform a Job Hazard Analysis?

V. Empower your Job Hazard Analysis with FAT FINGER

What is Job Hazard Analysis?

Job Hazard Analysis, or JHA, is a process of identifying and assessing the risks and hazards associated with a job or task. The goal of a JHA is to examine and eliminate any dangers before they can result in injuries, making the job less risky for everyone involved. Once the hazards have been identified, the safety professional will develop controls to mitigate the risks.

JHA can be used for any job or task, but it is often conducted for those identified as high-risk tasks.

Job Safety Analysis, or JSA, is a similar process used to identify and assess the risks and hazards associated with a job or task. However, JSA focuses on the controls that should be in place to prevent accidents and injuries. JSA is often used in conjunction with JHA to provide a comprehensive approach to job safety.

Several methods can be used to identify hazards, including:

– Reviewing past accidents and incidents

– Conducting a walk-around survey of the workplace

– Watching workers as they perform their tasks

– Consulting with workers about their experiences

– Using hazard identification checklists.

JHA is an essential tool for preventing workplace accidents and injuries and can also help improve productivity and efficiency.

Common Challenges to an Effective Job Hazard Analysis

Job Hazard Analysis can be challenging, and some common pitfalls can lead to ineffective results. A few of the most common problems are due to using a paper-based checklist rather than a digital one.

1. Most JHA papers did not include visual representations or reference information for control recommendations, unlike a digital checklist where photos, feedback, and suggestions can be easily attached.

2. Ineffective miscommunication. Paper-based checklists can be easily misplaced or lost, making it difficult to track progress or identify all hazards.

3. Paper forms are a significant inconvenience for employees and employers alike. They create more work when conditions change, which makes it challenging to stay up-to-date with all the latest information about your company’s hazard analysis.

For these reasons, using a digital checklist for Job Hazard Analysis is often beneficial.

Job Hazard Analysis is critical because it allows you to take proactive measures to control or eliminate potential hazards before they result in an accident or incident. Identifying risks early, can save lives, reduce injuries, and minimize property damage.

Job Hazard Analysis is the foundation for hazard control. A hazard assessment checklist is used to identify potential hazards in the workplace. It helps to prioritize controls by identifying the most severe hazard first. Hazard identification helps to establish baseline data for comparisons. For example, if you identified ten hazards in the workplace, and after implementing hazard controls, you only identified two hazards, you can show that the hazard controls are adequate.

How to Effectively Perform a Job Hazard Analysis?

Job Hazard Analysis is a crucial component of hazard assessment and risk management. JHA aims to identify potential hazards that could adversely affect the health or safety of people, property, or the environment. Effectively perform hazard analysis by following the steps below:

Step 1: Identify the hazard

When performing hazard assessment, it is important to first understand the types of hazards that can be present in a given workplace. Common hazard categories include physical hazards, chemical hazards, biological hazards, and ergonomic hazards.

Step 2: Evaluate the hazard

After the hazard has been identified, it needs to be evaluated to determine the potential severity and likelihood of an accident or incident occurring. The evaluation should consider the following factors:

– The consequences of an accident or incident

– The probability of an accident or incident occurring

– The number of people exposed to the hazard

– The severity of the hazard

– The existing controls for the hazard

Step 3: Take Action to Control the Hazard

After the hazard has been identified and evaluated, it is important to take action to control the hazard. There are a variety of ways to control hazards, including:

– Eliminating the hazard

– Substituting a less hazardous material

– Engineering controls

– Administrative controls

– Wearing personal protective equipment

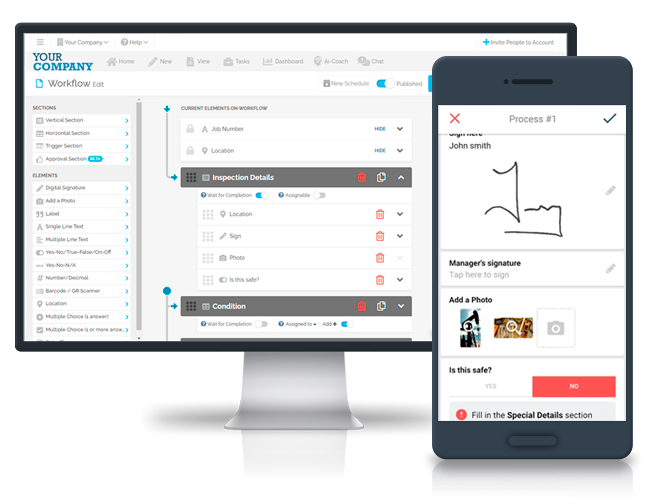

It’s hard to keep track of everything when you’re walking around a facility, inspecting for hazards.

Not only do you have to worry about keeping track of all your paperwork, but you also have to remember to take pictures and videos of potential hazards. And if you forget something, it can be hard to go back and fix it.

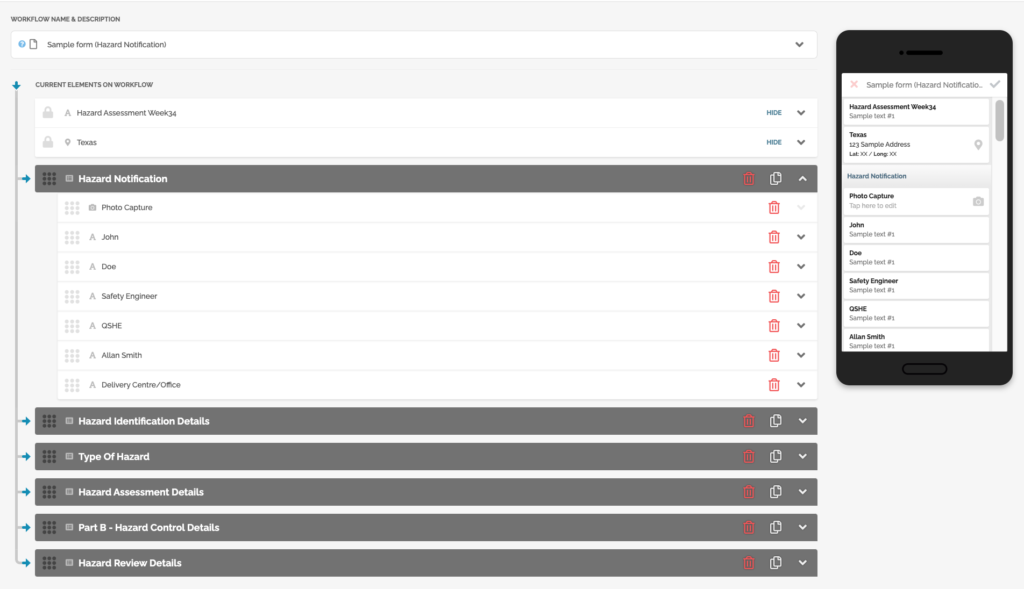

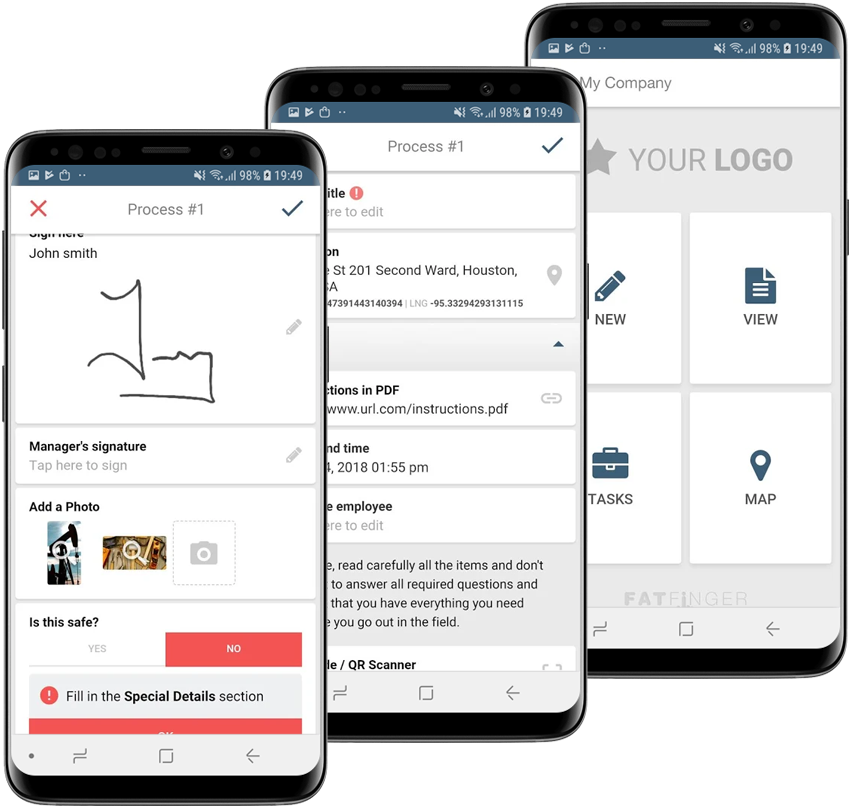

FAT FINGER is the solution. With our mobile app, you can easily capture media-rich knowledge with images and video to create Job Hazard Analysis workflows with no code directly where work is done. You’ll communicate hazard updates and automate and schedule an appointment so it’s done correctly every time. And best of all, identify critical areas to improve so you can pinpoint where you are performing and focus on your next area of improvement.

Empower your Job Hazard Analysis with FAT FINGER

A digital Job Hazard Analysis checklist like that of FAT FINGER has revolutionized how workplaces identify and control hazards, especially in the oil and gas, energy, and manufacturing sectors. It has replaced the traditional paper-based hazard identification checklist and brings forth many benefits, some of which are listed below:

– User-Friendly: The hazard identification checklist is digital and easy to use. Anyone can quickly learn how to use it with a few minutes of training.

– Accuracy at its finest: With a digital hazard identification checklist, you are less likely to make mistakes because you can easily review the data before you submit it.

– Efficient: A digital hazard identification checklist is faster and easier to use than a paper-based hazard identification checklist because you can quickly input data and add photos directly.

– Collaborative than ever: With a digital hazard identifier, you can easily share the hazard identification checklist with others in your organization.

– Update is a breeze: With a digital hazard identification checklist, you can quickly and easily update the information wherever and whenever.

-Goal-oriented: With a digital hazard identification checklist, you can easily track the type of hazards in your workplace and develop plans to control them.

Now that you know the benefits of using a digital hazard identification checklist, why not try one for your organization? FAT FINGER’s digital hazard identification checklist is easy to use and can help you improve the safety of your workplace.

You know that feeling when you walk into a room and can’t remember why you’re there? That’s how it feels when you’re trying to remember the last time you updated your hazard assessment.

FAT FINGER was created by safety professionals who understand the importance of capturing and communicating hazard information quickly, accurately, and efficiently.

Our mobile app makes it easy for you to take pictures and videos of your work area so you can identify potential hazards and create workflows without any coding required.

With FAT FINGER, hazard assessment is simple. Get started today by downloading our free trial!

About FAT FINGER

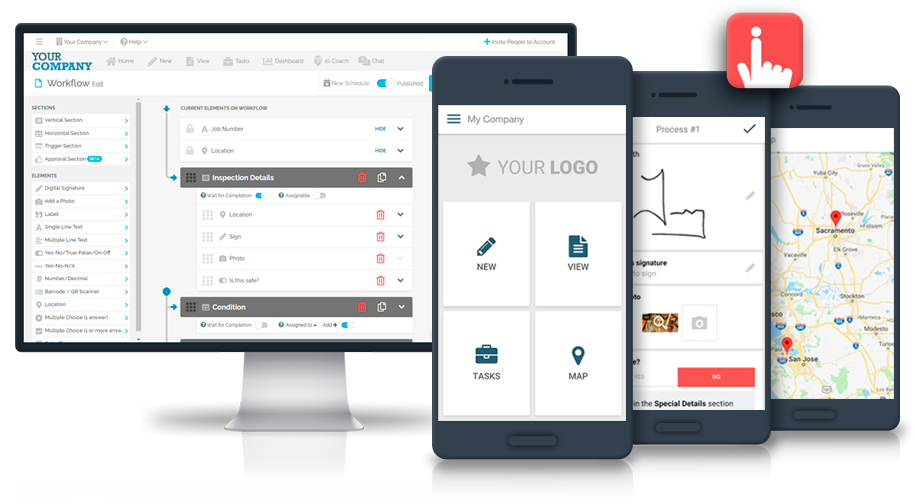

Ensure front-line teams do their work correctly every time. Drag & drop digital procedures that unlock operational excellence.

In seconds anyone can build and deploy enterprise-grade mobile applications using an easy drag-and-drop no-code builder.

FAT FINGER uses machine learning to coach app users in real-time to make safer and improved decisions.

Try building your digital procedure on FAT FINGER for free @ www.fatfinger.io

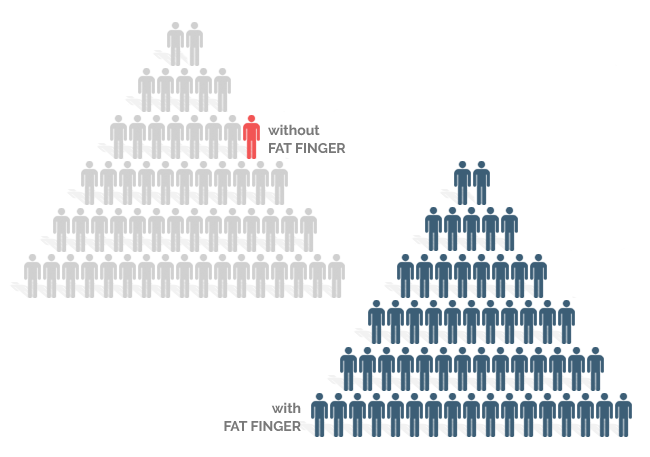

JHA for everyone – Anytime and anywhere.

We empower EVERYONE to initiate and create positive change to improve the company’s safety records no matter where you are. The only way to keep up with the speed at which the world moves today is to empower everyone from the front-line worker to the executive.

Intuitive digital workflow – Paperless and powerful.

FAT FINGER is designed to streamline the data collection process. With our intuitive workflow, you can quickly customize your data collection with images and annotations to create workflows with No-Code directly where work is done. Automatically generate a professional report with one click and share them with anyone.

Data powerhouse – Keeping everything in one place.

Data are stored in the cloud and available in real-time to everyone who needs it. All your up-to-date safety work instructions and training content are available across any device as employees perform the work.

Advanced Analytics- What gets measured, gets managed.

Every single piece of information captured by FAT FINGER users will feed your company analytics in real time. FAT FINGER provides you with valuable insights to help improve your workplace safety. With detailed dashboards, you can quickly identify areas of improvement and track your progress over time.