As the mining industry continues to evolve, the need for efficient and reliable data collection methods has become increasingly important. This is where FAT FINGER comes in. FAT FINGER is a digital workflow procedure builder that allows you to create checklists, workflows, and digital procedures that unlock operational excellence. In this article, we will delve into how you can leverage FAT FINGER to build field data collection apps for your mining operations. But first, why not schedule a demo to see FAT FINGER in action?

Understanding FAT FINGER

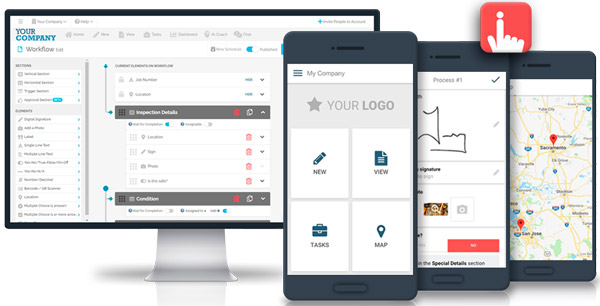

FAT FINGER is a software solution designed to streamline operations in various industries, including mining. It offers a range of features that can be tailored to meet the unique needs of your mining operations. These features include:

- Real-time data collection and reporting

- Customizable digital forms and checklists

- Workflow automation

- Integration with existing systems

- Cloud-based access for remote teams

Why Use FAT FINGER for Mining Operations?

The mining industry is characterized by complex processes, hazardous environments, and stringent regulatory requirements. FAT FINGER’s features provide solutions to these challenges by enabling:

- Improved safety: By digitizing safety checklists and procedures, FAT FINGER ensures that safety protocols are followed consistently.

- Increased efficiency: Real-time data collection and reporting allow for quick decision-making and problem-solving.

- Regulatory compliance: Digital record-keeping makes it easier to demonstrate compliance with industry regulations.

Building Field Data Collection Apps with FAT FINGER

Now that we understand the benefits of FAT FINGER, let’s delve into how you can use it to build field data collection apps for your mining operations.

Step 1: Define Your Data Collection Needs

Before you start building your app, it’s crucial to identify what data you need to collect. This could include safety checks, equipment inspections, or production data. Once you’ve defined your needs, you can start designing your app to meet these requirements.

Step 2: Customize Your Digital Forms

FAT FINGER allows you to create custom digital forms that fit your data collection needs. You can include various fields, such as text boxes, checkboxes, and dropdown menus, to capture the necessary data.

Step 3: Automate Your Workflows

With FAT FINGER, you can automate your data collection workflows. This means that once data is entered into a form, it can automatically trigger the next step in the process, such as sending a report to a supervisor or scheduling a maintenance task.

Step 4: Integrate with Existing Systems

FAT FINGER can be integrated with your existing systems, allowing you to streamline your operations further. For example, data collected through your app can be automatically uploaded to your database or management system.

Case Study: Improving Safety in Mining Operations

One mining company used FAT FINGER to digitize their safety checklists. This allowed them to ensure that safety protocols were followed consistently, reducing the risk of accidents. Additionally, real-time reporting enabled them to quickly identify and address any safety issues, further improving their safety record.

Conclusion

Building field data collection apps for mining operations with FAT FINGER can significantly improve your operations’ efficiency, safety, and compliance. By defining your data collection needs, customizing your digital forms, automating your workflows, and integrating with existing systems, you can unlock operational excellence in your mining operations.

Ready to get started? Build a digital workflow for free on FAT FINGER or schedule a demo today.