The oil and gas industry is a complex and high-stakes environment where asset inspection is a critical component of operations. Ensuring the integrity and functionality of assets is paramount to maintaining productivity, safety, and regulatory compliance. This article will delve into the essential tools for effective asset inspection in the oil and gas industry, with a particular focus on the innovative solutions provided by FAT FINGER.

Experience the power of digital workflows for asset inspection by requesting a demo of FAT FINGER today.

Traditional Tools for Asset Inspection

Traditionally, asset inspection in the oil and gas industry has relied on a range of tools, including:

- Visual inspection tools such as borescopes and drones

- Non-destructive testing (NDT) equipment like ultrasonic and radiographic testing devices

- Corrosion monitoring devices

- Pressure and temperature gauges

While these tools have served the industry well, they come with their own set of challenges. These include high costs, time-consuming processes, and the potential for human error.

The Rise of Digital Solutions: FAT FINGER

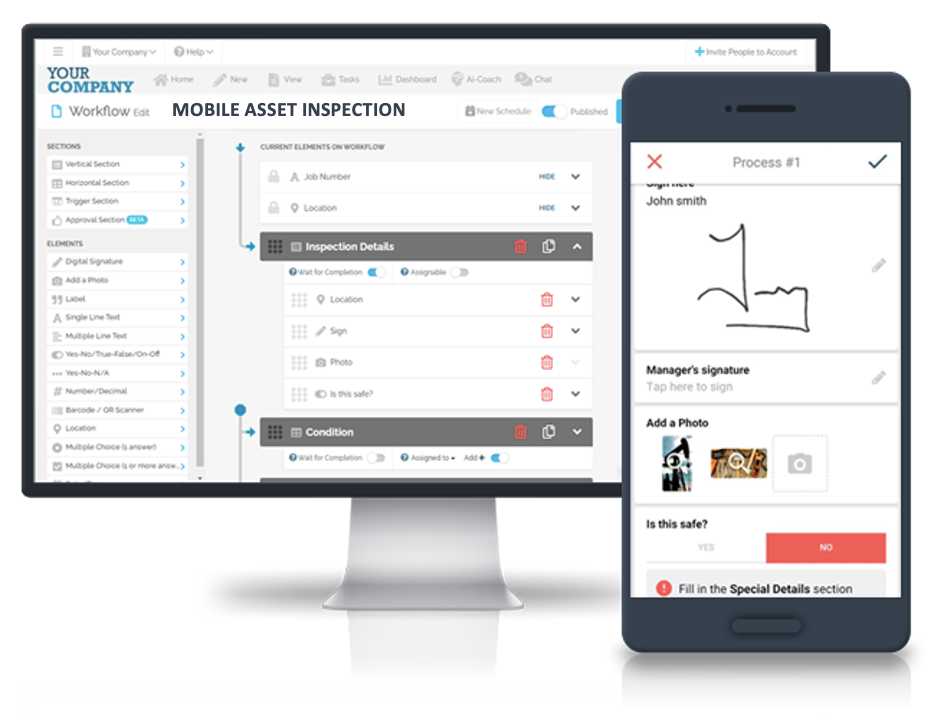

As the industry evolves, so too do the tools used for asset inspection. Digital solutions are increasingly being adopted to streamline processes, improve accuracy, and reduce costs. One such solution is FAT FINGER, a platform that offers mobile asset inspection workflows designed specifically for the oil and gas industry.

Benefits of FAT FINGER for Asset Inspection

FAT FINGER provides a host of benefits for asset inspection in the oil and gas industry:

- Real-time data collection and analysis: FAT FINGER allows for immediate data capture and analysis, enabling faster decision-making and problem-solving.

- Reduced human error: By digitizing inspection processes, FAT FINGER minimizes the risk of human error, enhancing the accuracy and reliability of inspections.

- Improved compliance: FAT FINGER’s digital workflows ensure that all inspection processes are carried out in accordance with industry regulations, aiding in compliance efforts.

- Cost savings: By streamlining and automating inspection processes, FAT FINGER can significantly reduce operational costs.

Case Study: FAT FINGER in Action

One notable example of FAT FINGER’s effectiveness in the oil and gas industry is its implementation by a leading oil and gas company. The company was struggling with inefficient and error-prone manual inspection processes. After implementing FAT FINGER’s mobile asset inspection workflows, the company saw a 60% reduction in inspection time, a 30% decrease in equipment downtime, and a significant improvement in data accuracy.

Conclusion

Asset inspection is a critical aspect of operations in the oil and gas industry. While traditional tools have their place, the future lies in digital solutions like FAT FINGER. With its real-time data collection and analysis, reduced human error, improved compliance, and cost savings, FAT FINGER is revolutionizing asset inspection in the oil and gas industry.

Experience the benefits of FAT FINGER’s mobile asset inspection workflows for yourself. Create a mobile asset inspection workflow for free on FAT FINGER today. Click here to get started, or request a demo to see FAT FINGER in action.