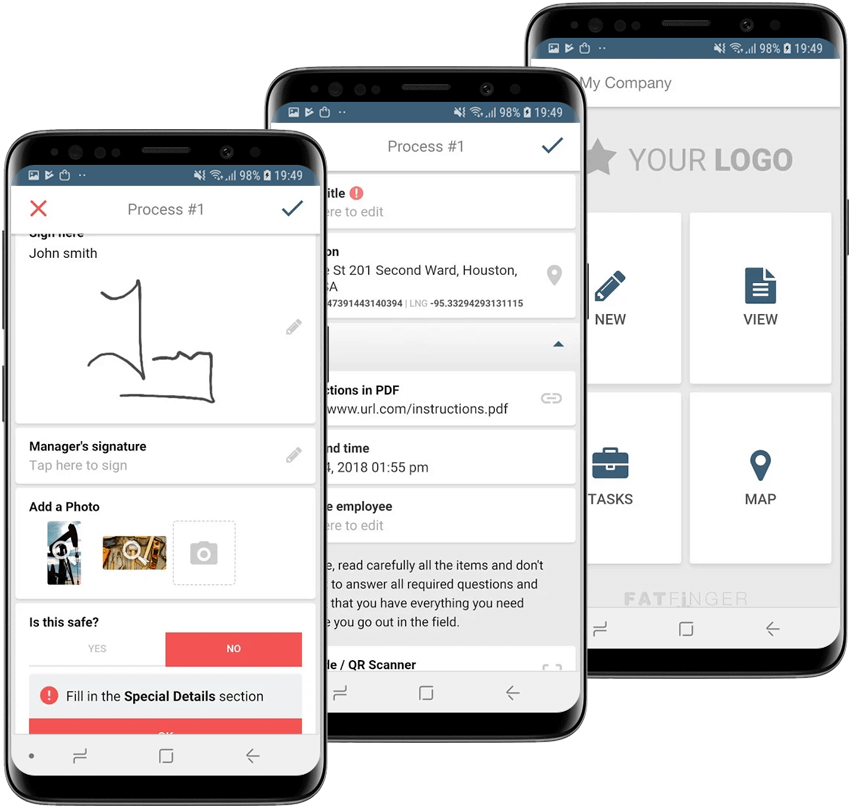

In the era of climate change and environmental consciousness, the maintenance of energy systems is no longer just about efficiency and cost-effectiveness. It’s also about sustainability and reducing environmental impact. This is where FAT FINGER comes into play. FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. With FAT FINGER, you can build checklists, workflows, and digital procedures that unlock operational excellence while also considering environmental factors. Request a demo today to see how FAT FINGER can revolutionize your energy system maintenance.

The Importance of Environmental Considerations

Environmental considerations in energy system maintenance are crucial for several reasons. Firstly, energy systems often involve the use of non-renewable resources, which can have a significant environmental impact. Secondly, the processes involved in energy production and distribution can result in emissions that contribute to climate change. Lastly, the waste produced by these systems can harm the environment if not properly managed.

How FAT FINGER Can Help

FAT FINGER can help you address these environmental considerations in several ways. Here are some powerful checklists you can build with FAT FINGER to boost operational efficiency while also reducing environmental impact:

- Material Inspection: Ensure the highest quality standards of your products with a digital material inspection. Identify defects early in the production process before they become too costly and result in waste.

- Quality Control: Ensure that what your customers get presents the best of your brand while also minimizing waste and emissions.

- Shift Handover: Modernize your shift transition to save time and resources.

- Facility Inspection: Ensure your facility keeps running without a hitch while also identifying potential environmental risks.

- Line Changeover: Seamlessly transition between processes to maximize productivity and minimize waste.

- Electronic Field Ticket: Streamline productivity and reduce paper waste with automated field reporting, workforce scheduling, and invoicing.

Case Study: The Impact of FAT FINGER

One energy company that implemented FAT FINGER saw a significant reduction in their environmental impact. By using the Material Inspection and Quality Control checklists, they were able to identify defects early and reduce waste. The Facility Inspection checklist helped them identify potential environmental risks and take action to mitigate them. The Shift Handover and Line Changeover checklists streamlined their processes, saving time and resources. Finally, the Electronic Field Ticket eliminated the need for paper tickets, reducing their paper waste.

Conclusion

Environmental considerations in the maintenance of energy systems are more important than ever. With FAT FINGER, you can build digital workflow procedures that not only improve operational efficiency but also reduce environmental impact. From material inspection to electronic field tickets, FAT FINGER offers a range of solutions to help you maintain your energy systems in a sustainable way. So why wait? Build a safety checklist with FAT FINGER today and take a step towards a more sustainable future.

Take a step towards a sustainable future by considering environmental aspects in the maintenance of your energy systems. Learn more about how you can make a difference by visiting FAT FINGER. Act now for a greener tomorrow.