In today’s fast-paced digital era, businesses are constantly seeking innovative ways to streamline their operations and improve efficiency. One such area that has seen significant transformation is Field service management. With the advent of Mobile technologies, companies are now able to manage their Field operations more effectively and efficiently. A prime example of this is FAT FINGER, a digital workflow procedure builder that empowers front-line teams to do their work correctly every time.

Understanding Field Service Management

Field service management (FSM) involves coordinating company resources employed at or en route to client sites, rather than on company property. Examples include locating vehicles, managing worker activity, scheduling and dispatching work, ensuring driver safety, and integrating such activities with inventory, billing, accounting and other back-office systems.

The Role of Mobile Technologies in FSM

Mobile technologies have revolutionized FSM by providing real-time access to information, improving communication, and enhancing productivity. They enable field service workers to access critical data and resources from anywhere, at any time, thereby improving service delivery and customer satisfaction.

How FAT FINGER Enhances FSM

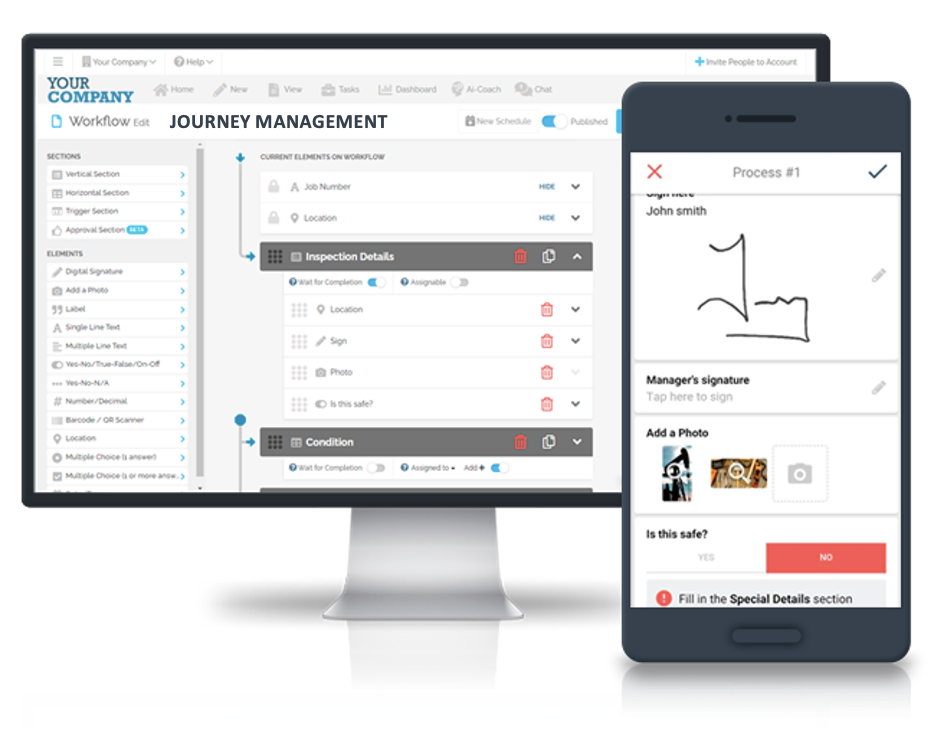

FAT FINGER, with its robust features such as Drag & Drop Workflow Builder, Mobile & Desktop Workflows, Dashboards, Integrations, Augmented Reality, Connect IoT Devices, and Artificial Intelligence Coaching, is a game-changer in the field of FSM. It allows businesses to build checklists, workflows, and digital procedures that unlock operational excellence.

FAT FINGER can be utilized across various safety, maintenance, and operations areas. Here are some of the solutions it offers:

- Safety: Take 5 Safety, Near miss reporting, JSA / JHA, Risk Assessment, Incident reporting, Journey report

- Operations: Material Inspection, Quality Control, Shift Handover, Facility inspection / Production rounds, Line Changeover, Field ticket

- Maintenance: Work Order Checklist, Truck inspection checks, Mobile Asset Inspection, Shutdown / Turnaround form, Preventive maintenance inspection, Predictive Maintenance

Case Study: The Impact of FAT FINGER on FSM

A leading manufacturing company implemented FAT FINGER to streamline its field service operations. The company was able to reduce its paperwork by 60%, improve its first-time fix rate by 30%, and increase its customer satisfaction rate by 20%. This case study clearly demonstrates the transformative potential of FAT FINGER in enhancing FSM.

Conclusion: The Future of FSM with Mobile Technologies

Mobile technologies, particularly digital workflow procedure builders like FAT FINGER, are set to redefine the future of FSM. They offer unprecedented levels of efficiency, flexibility, and control, enabling businesses to deliver superior service and achieve operational excellence. As more companies recognize the benefits of these technologies, their adoption is only set to increase.

Are you ready to transform your Field service management with FAT FINGER? Sign up today or request a demo to see how our solutions can empower your front-line teams to do their work correctly every time.