Quality Control is a critical aspect of any manufacturing process, and the electronics sector is no exception. With the increasing demand for high-quality electronic products, manufacturers are constantly seeking innovative ways to ensure their products meet the highest standards. One such innovation is the use of digital workflow procedure builders like FAT FINGER. This powerful tool empowers front-line teams to do their work correctly every time, unlocking operational excellence. In this article, we will explore various quality control techniques in the electronics manufacturing sector and how FAT FINGER can enhance these processes.

Quality Control Techniques in Electronics Manufacturing

Quality control in electronics manufacturing involves a series of checks and balances to ensure that the final product meets the desired specifications. Here are some of the most common techniques:

- Visual Inspection: This is the most basic form of quality control, where the product is visually inspected for any defects.

- Functional Testing: This involves testing the functionality of the electronic device to ensure it operates as intended.

- Automated Optical Inspection (AOI): This is a non-contact testing method that uses a camera to capture images of the product and compare them with the desired specifications.

- X-ray Inspection: This technique is used to inspect the internal components of the product without disassembling it.

Enhancing Quality Control with FAT FINGER

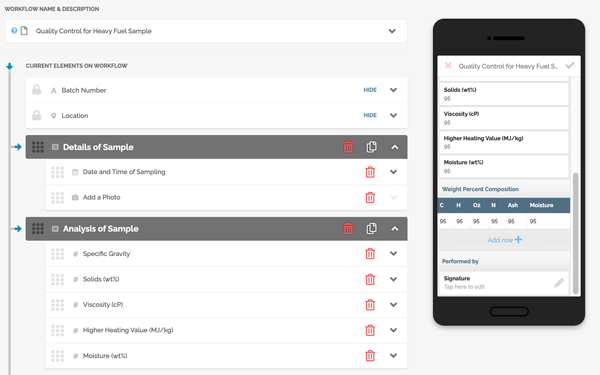

FAT FINGER is a digital workflow procedure builder that can significantly enhance the quality control process in electronics manufacturing. With its drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and artificial intelligence coaching, FAT FINGER can streamline and automate various aspects of quality control. Here’s how:

Material Inspection

With FAT FINGER, you can build a digital material inspection checklist that ensures the highest quality standards of your products. This revolutionary workflow allows for quick and accurate inspection of materials, identifying defects early in the production process.

Quality Control

FAT FINGER enables you to automate your quality control process, ensuring that what your customers get presents the best of your brand. With its smart workflow, you can transition from paperwork processes to digital ones in minutes, generating custom reports that keep everyone on track for operational excellence.

Shift Handover

Modernize your shift transition with FAT FINGER’s checklist that keeps your team moving. Automate tedious tasks and ensure clear communication that maximizes output while saving time.

Facility Inspection

Ensure your facility keeps running without a hitch with FAT FINGER’s effective facility inspection workflow. Streamline your checklists, SOPs, and inspections, generating professional reports in an instant.

Line Changeover

Seamlessly transition between processes with FAT FINGER’s line changeover solution. Cut down tedious tasks like manual reporting and quality monitoring, getting your team synced up in no time with automated recurring scheduling.

Electronic Field Ticket

Upgrade your ticketing system with FAT FINGER’s electronic field ticket solution. Boost your team’s productivity with automated field reporting, workforce scheduling, and invoicing, setting up recurring projects in no time.

Conclusion

Quality control in the electronics manufacturing sector is crucial for ensuring the production of high-quality products. With digital workflow procedure builders like FAT FINGER, manufacturers can streamline and automate their quality control processes, enhancing efficiency and productivity. So why wait? Request a demo today and see how FAT FINGER can revolutionize your quality control process.

Ready to build a safety checklist with FAT FINGER? Get started today and unlock operational excellence in your facility.

Discover the latest Quality Control Techniques in the Electronics Manufacturing Sector. Enhance your production process, reduce errors, and ensure the highest quality of your electronic products. Request A Demo today to see how our solutions can improve your manufacturing operations.