As the manufacturing industry continues to evolve, the need for efficient raw material handling has become more critical than ever. This is where FAT FINGER comes into play. FAT FINGER is a digital workflow procedure builder that allows you to create checklists, workflows, and digital procedures that unlock operational excellence. With its robust features, FAT FINGER provides a comprehensive solution for efficient raw material handling in factories. In this article, we will delve into how FAT FINGER can revolutionize your factory operations.

But first, schedule a demo to see it in action.

Understanding FAT FINGER

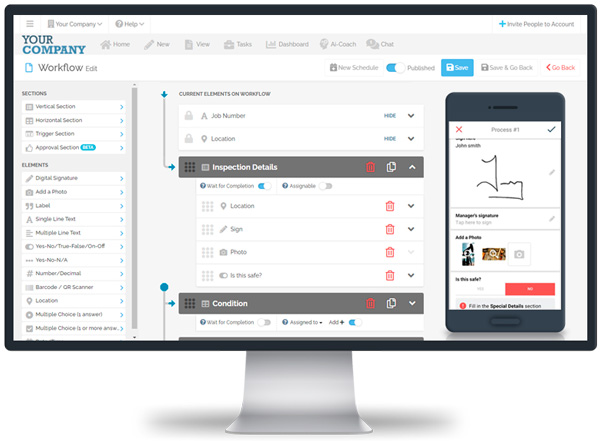

FAT FINGER is a software solution designed to streamline operations in various industries, including manufacturing. It allows users to build custom apps without any coding knowledge, making it a versatile tool for any factory setting. The software is designed to improve efficiency, reduce errors, and enhance overall operational excellence.

Key Features of FAT FINGER

- Easy App Building: FAT FINGER allows you to build custom apps with a simple drag-and-drop interface. No coding knowledge is required.

- Real-Time Analytics: With FAT FINGER, you can track your operations in real-time, allowing you to make data-driven decisions.

- Integration: FAT FINGER seamlessly integrates with other systems, ensuring smooth operations.

How FAT FINGER Enhances Raw Material Handling

Raw material handling is a critical aspect of any manufacturing process. It involves the movement, storage, control, and protection of materials throughout the manufacturing process. Here’s how FAT FINGER can help:

Streamlining Workflow

FAT FINGER allows you to create custom workflows for raw material handling. This means you can design a process that suits your specific needs, ensuring efficiency and accuracy.

Reducing Errors

With FAT FINGER, you can create checklists that ensure every step of the raw material handling process is followed accurately. This reduces the chances of errors and enhances overall productivity.

Improving Traceability

FAT FINGER’s real-time analytics feature allows you to track raw materials throughout the manufacturing process. This improves traceability and allows for better inventory management.

Case Study: Improving Efficiency with FAT FINGER

Let’s take a look at a real-life example of how FAT FINGER can improve raw material handling. One of our manufacturing clients was struggling with inefficiencies in their raw material handling process. They were experiencing delays, errors, and a lack of traceability. After implementing FAT FINGER, they were able to create custom workflows and checklists, which significantly reduced errors. The real-time analytics feature allowed them to track their raw materials in real-time, improving traceability and inventory management. As a result, they saw a significant improvement in their overall efficiency.

Conclusion

In conclusion, FAT FINGER is a powerful tool for improving raw material handling in factories. Its easy app building, real-time analytics, and integration features make it a comprehensive solution for any manufacturing setting. By streamlining workflows, reducing errors, and improving traceability, FAT FINGER can significantly enhance operational excellence.

So why wait? Build a digital workflow for free on FAT FINGER or schedule a demo today to see how it can revolutionize your factory operations.