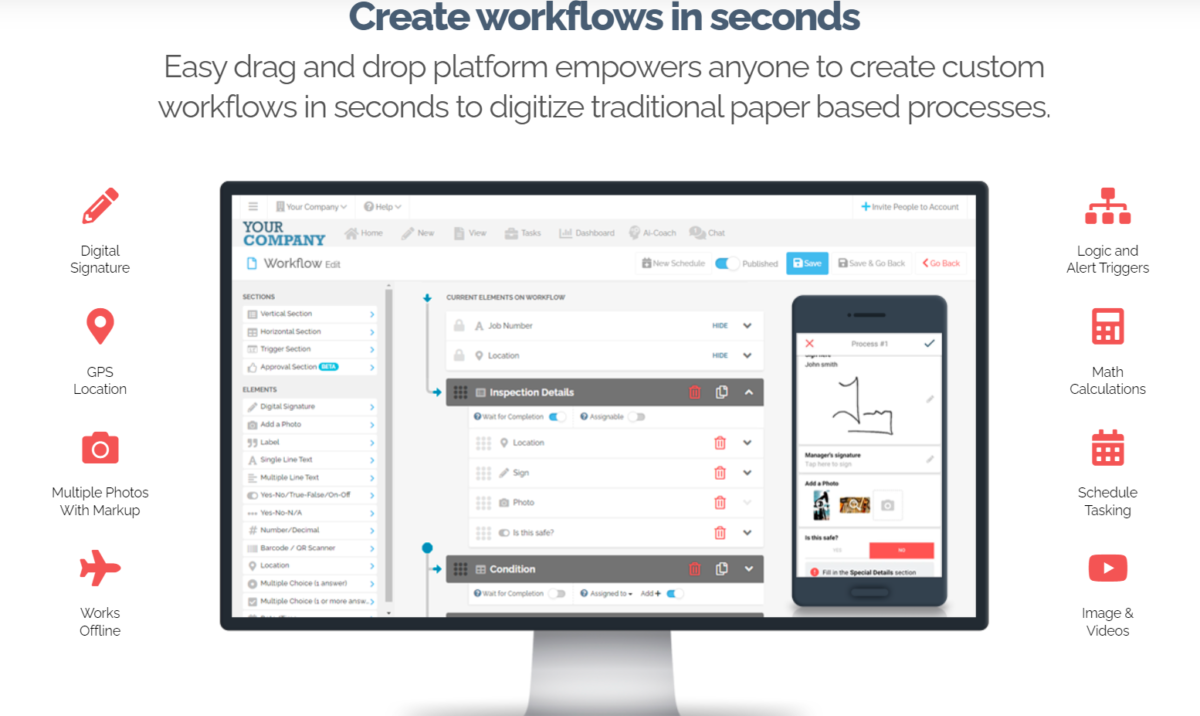

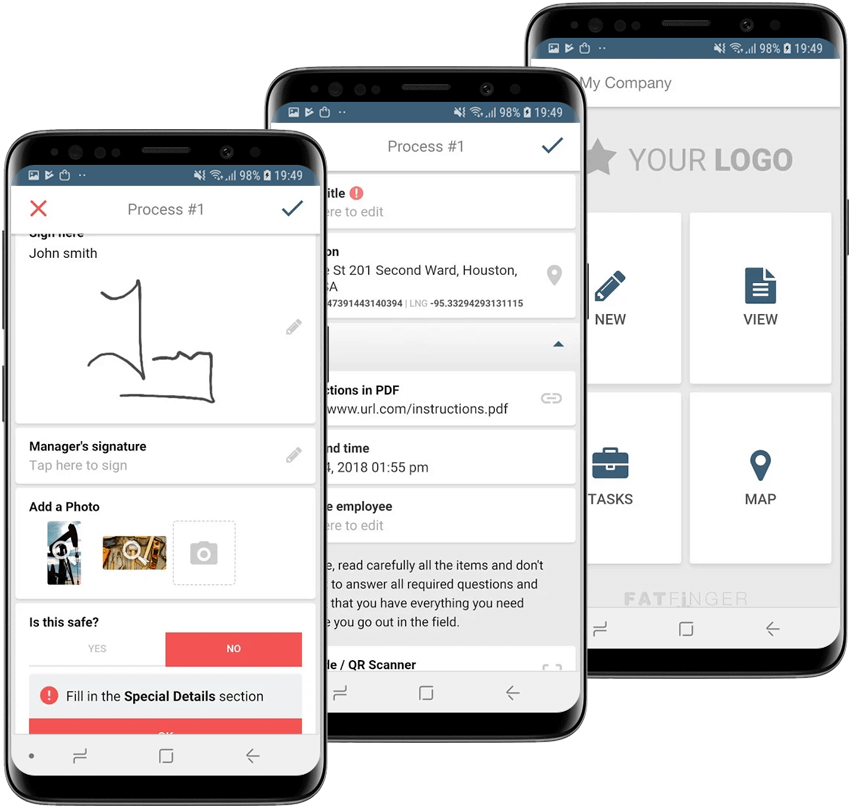

As businesses strive to achieve operational excellence, the role of digital workflows in early anomaly detection cannot be overstated. One such tool that is revolutionizing the way businesses operate is FAT FINGER. This digital workflow procedure builder empowers front-line teams to perform their tasks correctly every time, thereby enhancing efficiency and productivity. With features like Drag & Drop Workflow Builder, Mobile & Desktop Workflows, Dashboards, Integrations, Augmented Reality, Connect IoT Devices, and Artificial Intelligence Coaching, FAT FINGER is unlocking new dimensions of operational excellence.

Understanding Anomaly Detection

Anomaly detection, also known as outlier detection, is the act of identifying data points, items, or events that do not conform to an anticipated pattern within a given dataset. This process is important in various fields, including but not limited to, finance, IT, aerospace, and healthcare, where even a minor anomaly can have significant consequences.

The main objective of anomaly detection is to identify cases that are unusual within data that is seemingly homogeneous. In essence, it is about detecting the ‘exception to the rule’. The identification of these intrusions can lead to the discovery of truly significant, actionable information, from credit card fraud, to system health monitoring, to faults in an industrial manufacturing line.

In a business context, anomaly detection can provide valuable insight into a wide array of situations. For instance, an unexpected drop in the quality of products from a production line may be caused by a fault in the machinery. By identifying this anomaly quickly, a company can undertake corrective measures to mitigate the impact on production, reduce waste, and maintain product quality.

Similarly, in the realm of cybersecurity, anomaly detection plays a pivotal role. Cyber threats are increasingly becoming sophisticated, and traditional methods of securing systems are often insufficient. By tracking normal system behavior and flagging any deviations, anomaly detection systems can identify potential security breaches or attacks, enabling swift action to protect sensitive data and maintain system integrity.

In conclusion, anomaly detection is a critical process that can provide valuable insights for businesses, prevent potential faults or breaches, and even help in identifying new market opportunities. It is an essential tool in today’s data-driven world.

The Role of Digital Workflows in Anomaly Detection

Digital workflows play a crucial role in anomaly detection. They streamline and automate business processes, making it easier to monitor operations and identify any deviations from the norm. This early detection of anomalies allows businesses to take corrective action promptly, preventing potential issues from escalating into major problems.

How FAT FINGER Facilitates Early Anomaly Detection

FAT FINGER’s digital workflows and checklists are designed to facilitate early anomaly detection across various safety, maintenance, and operations areas. Here’s how:

- Safety: From Take 5 Safety and Near Miss Reporting to Incident Reporting and Journey Report, FAT FINGER ensures that safety procedures are followed to the letter, thereby minimizing the risk of accidents and injuries.

- Operations: Whether it’s Material Inspection, Quality Control, Shift Handover, or Facility Inspection, FAT FINGER’s digital workflows ensure that all operational procedures are carried out efficiently and effectively, thereby enhancing productivity and profitability.

- Maintenance: With features like Work Order Checklist, Mobile Asset Inspection, and Predictive Maintenance, FAT FINGER helps businesses maintain their assets in top condition, thereby minimizing downtime and maximizing operational efficiency.

Case Study: FAT FINGER in Action

A leading manufacturing company implemented FAT FINGER’s digital workflows to streamline its operations. The company was able to detect anomalies in its production line early, thereby preventing potential breakdowns and saving significant costs. The company also reported improved efficiency and productivity, thanks to FAT FINGER’s easy-to-use and customizable digital workflows.

The Bottom Line

Early anomaly detection using digital workflows like FAT FINGER can be a game-changer for businesses. It not only helps in preventing potential issues from escalating into major problems but also enhances efficiency and productivity, thereby driving operational excellence.

Ready to take your business to the next level?

Don’t wait for problems to escalate. Leverage the power of Early Anomaly Detection using digital workflows. Detect, analyze, and resolve issues before they become major problems. Start your journey towards proactive problem-solving today.