In the era of digital transformation, businesses are constantly seeking innovative ways to streamline their operations and enhance productivity. One such innovation that has proven to be a game-changer in various sectors, including manufacturing, is the use of advanced digital checklists. These digital tools, such as those offered by FAT FINGER, are designed to drive quality control by ensuring that tasks are performed correctly every time. FAT FINGER is a digital workflow procedure builder that empowers front-line teams to unlock operational excellence through the creation of checklists, workflows, and digital procedures.

Understanding the Role of Digital Checklists in Quality Control

Quality control is a critical aspect of any business operation. It involves the systematic inspection of products, services, or processes to ensure they meet the specified standards. Traditionally, quality control processes have been manual, time-consuming, and prone to human error. However, the advent of digital checklists has revolutionized these processes.

Digital checklists, like those created with FAT FINGER, provide a structured and standardized approach to quality control. They guide employees through the necessary steps of a process, ensuring that nothing is overlooked and that all tasks are performed correctly. This not only reduces the risk of errors but also enhances efficiency and productivity.

Moreover, digital checklists offer real-time tracking and reporting capabilities. This allows managers to monitor the progress of tasks, identify bottlenecks, and make informed decisions to improve the quality control process. Furthermore, with features such as drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, and artificial intelligence coaching, FAT FINGER takes digital checklists to a whole new level.

The Impact of Advanced Digital Checklists on Manufacturing Quality Control

In the manufacturing sector, quality control is of paramount importance. Any lapse in quality can lead to product recalls, customer dissatisfaction, and significant financial losses. Advanced digital checklists have emerged as a powerful tool to enhance manufacturing quality control.

Digital checklists facilitate the standardization of manufacturing processes. They provide clear, step-by-step instructions for workers, ensuring that every product is manufactured to the same high standards. This not only improves product quality but also reduces waste and increases efficiency.

Furthermore, digital checklists enable real-time data collection and analysis. This allows manufacturers to identify trends, detect anomalies, and take corrective action before minor issues escalate into major problems. For instance, FAT FINGER’s dashboards provide a visual representation of data, making it easier for managers to monitor and improve manufacturing quality control.

Exploring the Benefits of Digital Checklists in Various Sectors

While the benefits of digital checklists in manufacturing are evident, their application extends to various other sectors as well. In healthcare, for example, digital checklists can help ensure that medical procedures are performed correctly, reducing the risk of complications and improving patient outcomes.

In the construction industry, digital checklists can enhance safety by ensuring that all safety protocols are followed. They can also improve project management by providing a clear overview of tasks and their progress.

In the hospitality industry, digital checklists can enhance customer service by ensuring that all aspects of service delivery are up to standard. They can also help manage inventory and streamline operations.

The Future of Quality Control with Digital Checklists

The future of quality control lies in the use of advanced digital checklists. These tools not only drive efficiency and precision but also foster a culture of continuous improvement. They enable businesses to adapt quickly to changes, identify opportunities for improvement, and strive for operational excellence.

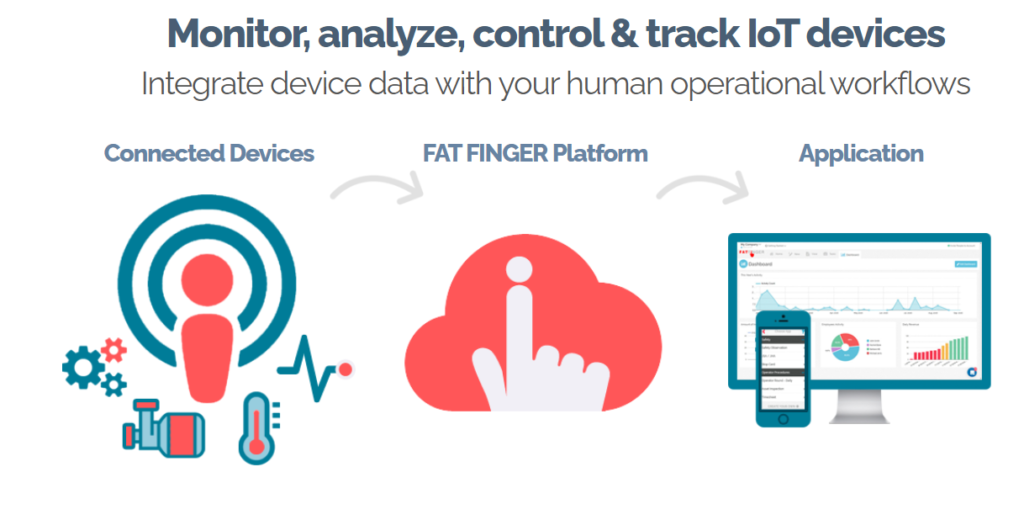

Moreover, with the integration of technologies such as IoT devices and artificial intelligence, digital checklists are becoming even more powerful. For instance, FAT FINGER’s AI coaching feature provides real-time guidance to workers, helping them perform tasks more effectively and efficiently.

Why Use FAT FINGER to build digital procedures and Checklists

FAT FINGER is a leading provider of digital checklist solutions. Its intuitive drag & drop workflow builder allows businesses to create custom checklists that meet their unique needs. With features such as mobile & desktop workflows, dashboards, integrations, augmented reality, and AI coaching, FAT FINGER empowers front-line teams to do their work correctly every time.

In conclusion, advanced digital checklists are transforming quality control processes in various sectors. They are driving efficiency, enhancing precision, and paving the way for operational excellence. To experience the power of digital checklists, sign up for FAT FINGER or request a demo today.

Start Transforming Your Processes Today: Explore how FAT FINGER can empower your transition with digital procedures and unlock new levels of efficiency and cost-effectiveness in your safety, operations and maintenance. Visit FAT FINGER for more information and to schedule a demo.