As the energy sector continues to evolve, the need for innovative safety solutions has never been more critical. One such solution is the use of digital twins in energy systems modeling. This technology, when combined with the power of FAT FINGER, a digital workflow procedure builder, can significantly enhance safety and operational efficiency. FAT FINGER empowers front-line teams to do their work correctly every time, unlocking operational excellence. Request a demo today to see how FAT FINGER can revolutionize your safety procedures.

Understanding Digital Twins in Energy Systems Modeling

Digital twins are virtual replicas of physical systems, processes, or products. They allow for real-time monitoring, simulation, and analysis, providing valuable insights that can enhance safety and efficiency. In the energy sector, digital twins can be used to model complex energy systems, predict potential issues, and develop effective solutions.

The Role of FAT FINGER in Enhancing Safety

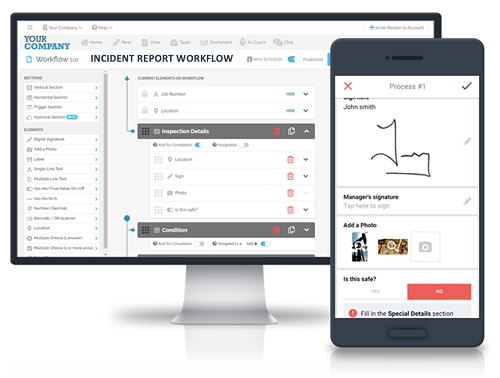

FAT FINGER plays a crucial role in enhancing safety by allowing you to build digital workflow procedures that make safety and preventive measures everyone’s responsibility. With FAT FINGER, you can build six powerful safety checklists:

- Take 5 Safety: Customize your Take 5 safety procedures to suit your site’s potential hazards.

- Near Miss Reporting: Stay ahead of potential issues through proactive monitoring.

- Job Hazard Analysis: Anticipate potential hazards and take preventative action.

- Risk Assessment: Protect yourself from threats with this smart solution.

- Incident Reporting in the Workplace: Ensure a safe and secure workplace with reliable digital workflows.

- Journey Report: Keep your people safe and their journey plans running smoothly with this efficient journey management solution.

Case Study: Enhancing Safety with FAT FINGER and Digital Twins

Consider a case where an energy company used FAT FINGER to build a digital twin of their energy system. The digital twin allowed them to simulate various scenarios, identify potential hazards, and develop effective safety procedures. By integrating these procedures into their FAT FINGER workflows, they were able to significantly enhance safety and operational efficiency.

Statistics Highlighting the Impact of Digital Twins and FAT FINGER

According to a report by Gartner, 75% of organizations implementing Internet of Things (IoT) already use digital twins or plan to within a year. Furthermore, a study by Accenture found that digital twins could unlock $1.3 trillion in economic value globally. When combined with the power of FAT FINGER, the potential for enhancing safety and efficiency is immense.

Conclusion

Enhancing safety in the energy sector is a critical task that requires innovative solutions. Digital twins in energy systems modeling, combined with the power of FAT FINGER, provide a powerful solution. By allowing you to build digital workflow procedures that make safety everyone’s responsibility, FAT FINGER can significantly enhance safety and operational efficiency. Don’t wait to revolutionize your safety procedures. Build a safety checklist with FAT FINGER today.

Discover how to enhance safety in energy systems modeling through digital twins. Learn more about this innovative technology and how it can revolutionize your safety protocols. Click here to get started.