Industrial shutdowns, also known as turnarounds, are critical periods in the lifecycle of industrial operations. They require meticulous planning, coordination, and execution to minimize downtime and maximize efficiency. In this context, connected work solutions like FAT FINGER can play a pivotal role. FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. It allows you to create checklists, workflows, and digital procedures that unlock operational excellence.

Understanding Industrial Shutdown Challenges

Industrial shutdowns are complex operations that involve a multitude of tasks, including safety checks, maintenance work, inspections, and more. These tasks need to be coordinated and executed in a precise sequence to ensure the shutdown is completed efficiently and safely.

- Time constraints: Shutdowns are costly, and every hour of downtime can result in significant financial losses. Therefore, it’s crucial to complete the shutdown as quickly as possible.

- Safety risks: Shutdowns involve high-risk activities, and any safety incident can lead to severe consequences.

- Quality control: Ensuring the quality of work during a shutdown is critical to prevent future operational issues.

How FAT FINGER Can Help

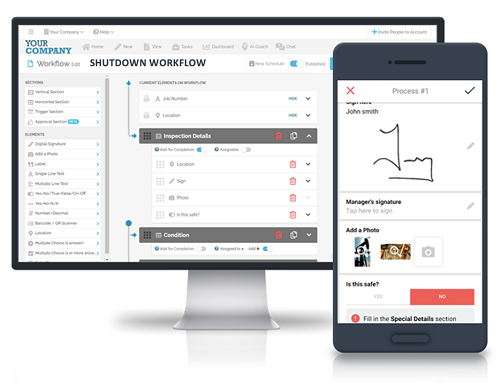

FAT FINGER offers a range of features that can help address these challenges, including a drag & drop workflow builder, mobile & desktop workflows, dashboards, integrations, augmented reality, IoT device connectivity, and artificial intelligence coaching.

Streamlining Shutdown Procedures with FAT FINGER

With FAT FINGER, you can create digital workflows and checklists for various safety, maintenance, and operations areas. These include:

- Safety: Take 5 Safety, Near miss reporting, JSA / JHA, Risk Assessment, Incident reporting, Journey report

- Operations: Material Inspection, Quality Control, Shift Handover, Facility inspection / Production rounds, Line Changeover, Field ticket

- Maintenance: Work Order Checklist, Truck inspection checks, Mobile Asset Inspection, Shutdown / Turnaround form, Preventive maintenance inspection, Predictive Maintenance

Case Study: Improving Shutdown Efficiency with FAT FINGER

Consider a case where a large industrial plant used FAT FINGER to streamline its shutdown procedures. The plant was able to reduce its shutdown time by 20% and improve its safety record by implementing FAT FINGER’s digital workflows and checklists. The plant also reported improved quality control and reduced rework, leading to significant cost savings.

Conclusion

Industrial shutdowns present unique challenges that require precise coordination and execution. Connected work solutions like FAT FINGER can help streamline these processes, reduce downtime, improve safety, and ensure quality control. By leveraging FAT FINGER’s features, industrial operations can overcome the challenges of shutdowns and achieve operational excellence.

Ready to transform your industrial shutdown procedures? Sign up for FAT FINGER or request a demo today to see how our solutions can help you overcome your unique industrial shutdown challenges.