As businesses strive to achieve operational excellence, the need for efficient and accurate data reporting tools becomes increasingly crucial. One such tool that has been making waves in the industry is FAT FINGER. FAT FINGER is a digital workflow procedure builder that empowers front-line teams to do their work correctly every time. It allows you to build checklists, workflows, and digital procedures that unlock operational excellence.

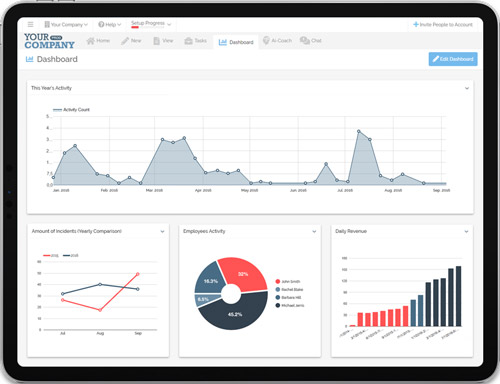

With features like Drag & Drop Workflow Builder, Mobile & Desktop Workflows, Dashboards, Integrations, Augmented Reality, Connect IoT Devices, and Artificial Intelligence Coaching, FAT FINGER is revolutionizing the way businesses operate.

Request a demo today to see how FAT FINGER can transform your business operations.

Developing Custom Reporting Tools for Production Data

Developing custom reporting tools for production data is a process that involves creating bespoke systems to collect, analyze, and present data related to manufacturing or production. This is a crucial process for businesses, as it can provide valuable insights and help in decision-making.

1. Understanding the Needs: The first step in developing custom reporting tools is understanding the needs of the business. What kind of data do they need? How often do they need reports? Who will use these reports? Answering these questions will help in designing the right tool.

2. Designing the Tool: Once the needs are understood, the next step is to design the tool. This may involve deciding on the type of software to use, the features it should have, and how it should present the data. The tool should be user-friendly and intuitive to use.

3. Data Collection: The tool needs to collect relevant data from various sources. This could be from machines in the production line, manual input from employees, or other software systems. The tool should be able to handle large volumes of data and collect it in real-time.

4. Data Analysis: After collecting the data, the tool needs to analyze it. This could involve calculating key performance indicators, identifying trends, or spotting anomalies. The tool should be able to process the data quickly and accurately.

5. Report Generation: Finally, the tool needs to generate reports based on the data analysis. These reports should be easy to understand, visually appealing, and customizable. They should also be available in various formats, such as PDF or Excel, for easy sharing and further analysis.

6. Training and Support: Once the tool is developed, users will need training on how to use it effectively. Ongoing support should also be provided to fix any issues and to make any necessary updates or improvements.

In conclusion, developing custom reporting tools for production data is a complex process that requires careful planning and execution. However, the benefits of having a tool tailored specifically to a business’s needs can be significant.

FAT FINGER: The Cost-Effective Solution To Develop Custom Reporting Tools

Developing a custom reporting tool with FAT FINGER is a cost-effective solution. Instead of investing in expensive standalone software, businesses can leverage the customizable and scalable solutions offered by FAT FINGER.

With the ability to adapt to various industrial domains and specific needs of businesses, FAT FINGER’s solutions can play a crucial role in enhancing operational efficiency and productivity.

Below is how FAT FINGER can improve your custom reporting needs:

1. Utilize the Drag & Drop Workflow Builder

FAT FINGER’s Drag & Drop Workflow Builder allows you to create custom workflows that align with your business processes. You can easily design and implement workflows that capture the necessary production data for your reports.

2. Leverage Mobile & Desktop Workflows

With FAT FINGER, you can create workflows that are accessible on both mobile and desktop platforms. This ensures that your team can input production data from anywhere, at any time, increasing the accuracy and timeliness of your reports.

3. Use Dashboards for Real-Time Reporting

FAT FINGER’s dashboards provide real-time reporting capabilities. You can customize these dashboards to display the most relevant production data, enabling you to make quick and informed decisions.

4. Integrate with Other Systems

FAT FINGER can be integrated with other systems in your business, allowing for seamless data flow. This integration ensures that your production data is always up-to-date and accurate, leading to more reliable reports.

5. Connect IoT Devices for Automated Data Collection

By connecting IoT devices, FAT FINGER can automate data collection from your production processes. This not only saves time but also reduces the chances of human error, resulting in more accurate reports.

6. Use Artificial Intelligence Coaching for Data Analysis

FAT FINGER’s Artificial Intelligence Coaching can help you analyze your production data and generate insightful reports. This feature can identify trends and patterns in your data, providing valuable insights for your business.

Conclusion

Developing custom reporting tools for production data is crucial for businesses to achieve operational excellence. With FAT FINGER, you can easily create these tools and gain valuable insights from your production data.

From designing custom workflows to integrating with other systems, FAT FINGER provides a comprehensive solution for your reporting needs.

So why wait? Build a digital workflow for free on FAT FINGER or schedule a demo today to see how FAT FINGER can transform your business operations.